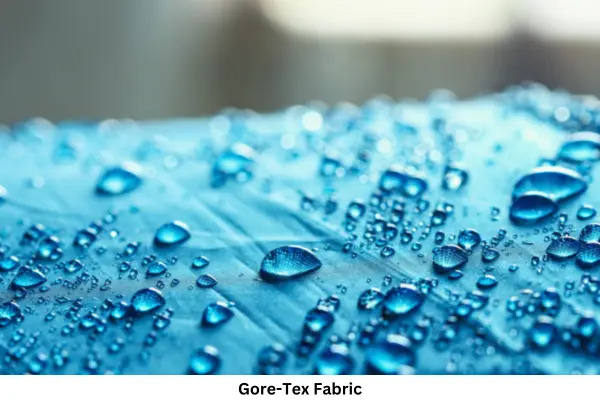

The term ‘Gore-Tex’ is so fascinating, that still it remains unknown to many. Those who like to make outdoor clothing must go through the fabric made of Gore-Tex. Not only the fabric would be highly durable but also the fabric is breathable.

PTFE, polytetrafluoroethylene is the core material that makes Gore-Tex, what we hear in today’s world. Read more to learn about the properties, types, and uses of Gore-Tex as a fabric.

Table Of Contents

What is Gore-Tex Fabric?

Gore-Tex fabric refers to the patented waterproof fabric. It is PTFE-made, more specifically ePTFE-made fabric. ePTFE is Polytetrafluroethylene. The fabric is stretchable after the post-production procedure. It contains tiny holes per inch. Water vapor consists of small particles. This allows vaporized sweat to pass through Gore-Tex. There are around nine billion pores in the Gore-Tex membrane per square inch of fabric.

The fabric remains effective if it goes through the treatment of water repellent (DWR). DWR is a chemical spray that keeps water off the Gore-Tex fabric’s surface. This chemical spray also allows breathability. Without this treatment, Gore-Tex becomes overheating-prone. Making seamless apparel, without DWR or chemical spray, becomes almost impossible.

How does Gore-Tex Fabric work?

Gore-Tex membrane comes into use in two different ways. One of the ways is:

-

Gore-Tex membrane gets bonded with heat and pressure. Durable-repellent coats contribute to the polyester and nylon-made fabric.

-

Garments that are three-layered get bonded to the Gore-Tex membrane to improve durability.

Gore-Tex Fabric Origin

The creator of the Gore-Tex fabric is Wilbert L. Gore. He is the founder of W.L.Gore and Associates. After beginning his career at the DuPont corporation, he became a noticeable individual with technological advancements. The last patent of W. L. Gore and Associates got approval in 1980.

It is four years after the Gore-Tex garments. After four years of getting approval, Gore-Tex appeared as the most popular fabric in the market. The Gore-SEAM tape helped W. L. Gore and Associates improve the waterproof properties of the Gore-Tex material.

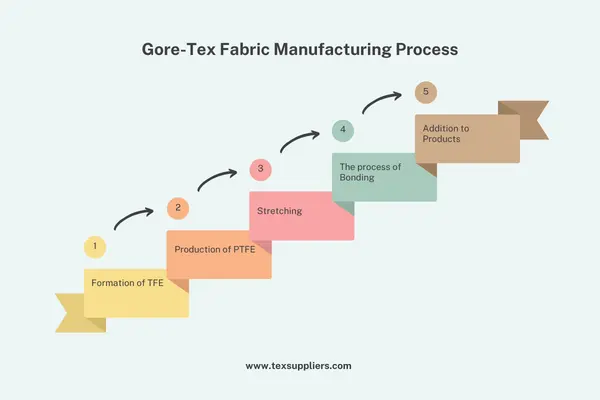

Gore-Tex Fabric Manufacturing Process

The manufacturing process of the Gore-Tex fabric is given below in steps:

-

Step 1: Formation of TFE: To form TFE, requires the combination of fluorspar, hydrofluoric acid, and chloroform. After taking the mixture to the heat exposure, these substances get combined.

-

Step 2: Production of PTFE: Next, TFE gets exposed to the initiator substance. To get the result in PTFE, the combination of water gets added.

-

Step 3: Stretching: PTFE goes through the heat exposure again. This time, it stretches quickly intending to form a thin filament.

-

Step 4: The process of Bonding: ePTFE and Polyurethane get bonded together when PTFE turns into a stretched ePTFE.

-

Step 5: Addition to Products: Gore-Tex fabric gets sewn underneath the garment's uppermost layer.

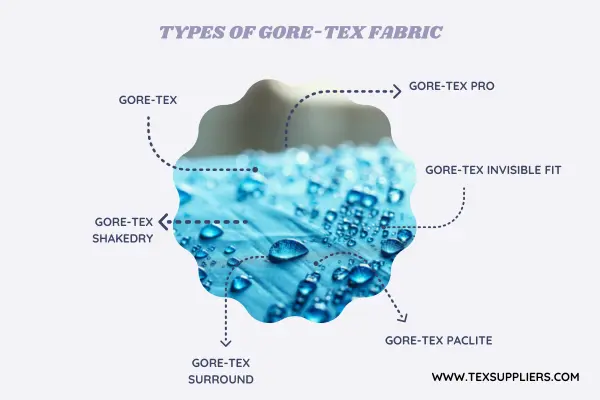

Types of Gore-Tex Fabric

Gore-Tex fabric comes in a variety of types. This fabric has several competitors too. For instance:

-

Gore-Tex: Gore-Tex, which we are discussing here, started to flourish in the decade of 1960s. The original Gore-Tex is widely used in a couple of applications. They are rain shells, jackets, and others. Gore-Tex is durable and highly versatile.

-

Gore-Tex Pro: Gore-Tex Pro is durable. It has uses in heavy-duty applications for outdoor use. Rock climbing equipment is one of them. Gore-Tex has an enhanced performance. It is popular in cold weather garments.

-

Gore-Tex Shakedry: This type of Gore-Tex is waterproof, lightweight, and breathable. It is ideal for athletic applications. For instance: Running and Cycling.

-

Gore-Tex Invisible Fit: Gore-Tex has developed this invisible fit. It directly bonds to the outer footwear surface. Besides, this invisible fit prevents water entry and other subsequent waterlogging.

-

Gore-Tex Surround: Gore-Tex is also useful as a footwear technology. It focuses on breathability. It provides significant waterproofing benefits.

-

Gore-Tex Paclite: Gore-Tex Paclite has development traced back to the late 1990s. It is lightweight, flexible, and trending.

-

Gore-Tex Infinium: Gore-Tex consists of materials that would benefit more in other areas except for waterproofing. Besides, materials in the Infinium line have enhanced breathability, insulation, and other benefits.

-

Columbia OutDry: OutDry type of Gore-tex solves one of the core issues. That is, waterproofing without providing any seams. Besides, this type is very breathable. It does not have any DWR coatings. DWR coatings offer a slightly less waterproof coating.

Gore-Tex Fabric Properties

|

Fabric Known As |

Waterproof Fabric |

|

Fabric Composition |

ePTFE fabric (Teflon made) |

|

Fabric Breathability |

High |

|

Moisture Wicking Abilities |

Medium |

|

Stretchability |

Low |

|

Prone to Pilling |

Low |

|

Washing Temperature |

Cold water; Machine wash is preferable |

|

Fabric Thickness |

0.01 mm |

|

Fabric GSM |

49 GSM in Side Panels |

|

Used in |

Jackets, Gloves, Medical Implants, Book Protectors. |

Characteristics of Gore-Tex Fabric

Here are some of the features of Gore-Tex Fabric:

-

Gore-Tex Membrane: The Gore-Tex membrane is a microporous material with breathability, windproof, and waterproof properties. It is made out of stretching PTFE (Polymer Polytetrafluoroethylene). The membrane is thin and ranges only 0.01 mm.

-

Availability of Production: W. L. Gore and Associates offers manufacturing facilities. However, the corporation hardly discloses any facilities related to the production of the fabric. Different countries are the United States, The United Kingdom, Japan, China, Germany, and of course the United States.

-

Impact on the Environment: Gore-Tex fabric has a negative impact when it comes to the environment. The production of PTFE is harmful to the environment. PTFE emits a variety of gases. It is available in powder form. If PTFE is inhaled, gases and powders can be significantly harmful. The fabric is breathable if Gore-tex is sprayed with DWR. DWR is a toxic substance for the environment.

-

Cost: Gore-Tex is a synthetic fabric. Sourcing from W.L. Gore Corporation causes expensive pricing. After getting Gore-Tex fabric, you will send the completed garments back to the corporation for certification.

What is Gore-Tex Fabric Used for?

Gore-Tex has uses in a variety of applications. For instance:

-

Apparel: Shells, Winter Jackets, Cycling Jackets

-

Accessories: Backpacks, Hats, Footwear

-

Industry: Vascular grafts, Space Suits, Sealing Batteries

-

Making of High-performance Fabrics

-

Medical Implants

-

Gaskets

-

Filter Media

-

Sealants

-

Protective rainwear

Gore-Tex fabric-made products can be both waterproof and not waterproof. Original Gore-Tex product technology has applications in jackets, gloves, and shoes.

Gore-Tex Fabric Care

Gore-tex fabric can last longer if it goes through convenient care procedures. Besides, regular care ensures excellent performance, continued coverage, and useful life. Detergents can reduce the product's breathability.

Gore-Tex garments require the following care procedures, they are

-

Machine wash on the 40 degrees Celsius cycle.

-

Use a small amount of detergent. Liquid is preferable to powder.

-

Any other detergents containing fabric softeners affect the performance of the garment

-

Avoid using bleach

-

Rinse twice on the low spin cycle.

-

Avoid dry cleaning

-

Avoid washing with heavily soiled clothing.

Conclusion

Gore-Tex became popular all because of its ability to be water-proof. Thanks to PTFE, polytetrafluoroethylene made the membrane of Gore-Tex thin, and breathable. As a fabric, Gore-Tex is pretty lightweight. It has uses in apparel, accessories, and industry, and many other areas.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.