Even a tiny performance problem in the thread can ruin investments in raw materials, machinery, garment engineering, and people's work. As a result, doing proper research on your thread is essential. Understanding thread, analyzing its properties in depth, using a suitable selection method, and making the best use of thread are all crucial parts of getting the sewing performance and seam quality you need. Therefore, in this article we will discuss different types of sewing thread and their properties.

Table Of Contents

What Are Sewing Threads?

Sewing thread is an important raw material that is used to give a garment its shape and make seams that hold the different parts of the body together. This item is important to the work of industrial garment makers, fashion companies, and tailoring shops.

Types of Sewing Threads

More than 90% of all sewing threads are produced for use in industrial and commercial settings. These days, producers are making threads in various categories according to the end purposes for which they are intended, with lots of color options and improved quality.

There are several different kinds of thread used for sewing, but the three most typical types are described as follows:

- The substrate

- The construction;

- Finish

Different Types of Sewing Threads Based on Their Substrates

Threads may be divided into two primary types, natural and synthetic, determined by the substrate they are made from.

i. Natural thread

In the industrial sector, they are sometimes utilized in relatively modest quantities. Cotton, silk, wool, linen, and other materials can be used to make it.

Silk

The price of silk thread is significantly higher compared to cotton thread. The majority of silk threads fall into one of these three categories. There are three weight categories: lightweight, medium-weight, and heavy. Due to its versatility, silk thread is most commonly used for embroidery, but it may also be found in items made of silk and woolen materials.

Because it is highly flexible and does not leave any holes in the seams of the items it sews, it makes an excellent sewing thread. It may be double or triple-ply, depending on your needs.

Cotton is the most common natural sewing thread and an excellent choice for beginner sewing projects. Sewing is more accessible with less kinking and dropped stitches thanks to its improved capabilities. When sewing machines are left running for extended periods, the needles produce heat, which cotton thread may readily absorb.

It is simple to color, and it also forms an excellent seam when it is molded. Natural threads have lower strength and lower resistance to abrasion than synthetic threads. The cotton may be divided into the following three groups according to its characteristics:

- Soft

- Glace

- Mercerized

Cotton threads that have already been finished are just bleached before being colored. Wax and other specialized chemicals are applied to the cotton threads used in lacemaking to give them a firm and glossy appearance.

They are superior to all other types of cotton threads in terms of their abrasion resistance. An acidic solution is applied to the surface of mercerized cotton threads to make them smoother, glossy, and more durable.

Wool

Woolen threads are used for embroidery projects because they are stronger than cotton and linen threads. Woolen cables are also used for creating stitches on blankets. There are three distinct types of woolen threads.

They are referred to as crewel, tapestry, and Persian. The weight of Persian woolen threads is heavy, whereas the importance of tapestry threads is medium, and the weight of crewel threads is light.

The oldest kind of textile thread is made from linen. It may be used for seams that require a lock stitch. It is simple to color, and it expands as it gets wet. A seam stitched with linen thread improves the aesthetic qualities of an article of clothing by giving it a more natural appearance.

ii. Sewing threads made of synthetic materials

Polyester and nylon are the two most prevalent synthetic materials used to create sewing thread. Natural fiber threads are more resistant to abrasion, whereas synthetic fibers are more robust, shrink less, and maintain their color well.

Synthetic fiber threads also have high colorfastness. Manufacturers developed synthetic fiber threads as a solution to the restrictions inherent in natural fiber threads.

Thread made of nylon.

This synthetic thread for stitching is superior in strength, fineness, and durability. It can handle the stitching of garments ranging from light to medium weight. Sometimes it is oiled explicitly to withstand high temperatures, improve performance without breaking or staining, and make it last longer.

Threads made of polyester

Polyester threads are superior in terms of their strength and capacity to be sewn. Lubrication is used to make them ready to easily travel through the cloth or leather with little resistance, which is accomplished by reducing the amount of friction they encounter.

The construction and finish of the item determine if these are ideal for stitching knitted, woven, or leather items. These are more attractive to the eye than regular cotton threads would be.

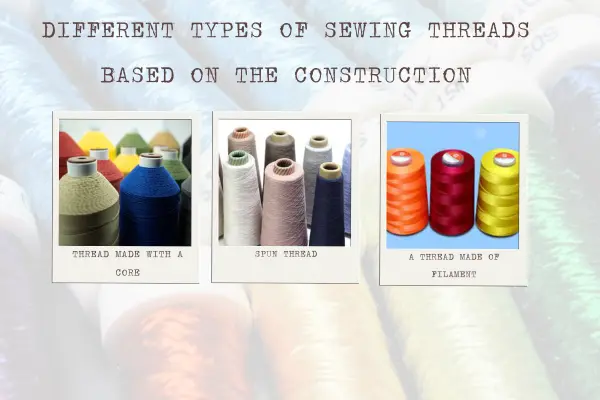

Different Types of Sewing Threads Based on The Construction

i. Thread made with a core

It is a thread used in industrial applications. When something is core-spun, it indicates that a continuous filament runs through the middle, and staple fibers are tangled up around it.

Regular spun the thread of the same weight is only around 40% to 50% as strong as this one. When sewing seams or hems on high-weight fabric like denim, using core-spun thread can help reduce the number of broken lines.

ii. Spun thread

Both natural and synthetic fibers can be used to create the spun thread. The natural fiber is often used more frequently. Polyester is by far the most popular choice for spun yarn. Short-length fibers are used in the production of staple or spun thread.

Natural staple fibers include cotton, wool, and flax, among others. Spun thread and staple thread are created by cutting synthetic fibers such as polyester or acrylic into short lengths and then twisting those lengths together. Staple or spun yarn can be used to create long-lasting and durable seams.

iii. A thread made of filament

It is possible to make it out of a single filament by twisting together more than one filament or giving bulk filaments a tiny bit of a twist. In general, there are three different kinds of filament threads, which are as follows:

a.Monofilament thread

It is constructed with a single strand of fiber throughout. It is less costly and has higher strength, but its use is restricted since it is less flexible and more rigid. One example of a natural monofilament thread that is continuous throughout is silk.

b. Multifilament thread

It is constructed from many continuous threads twisted into one another. This thread is often made from nylon or polyester fibers, both artificial materials. It is utilized in circumstances that call for increased tenacity.

c. Bulk filament

This thread is made up of several strands that are linked together and then given a very slight twist. Typically, polyester filaments are utilized in the manufacturing process. It is used for cover stitch seams and is skin safe, soft, and fluffy. It provides possible edge coverage.

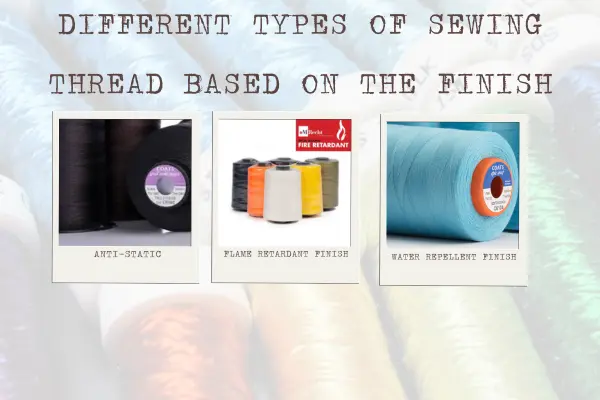

Different Types of Sewing Thread Based on The Finish

Finishes are applied to sewing threads at the finishing sections of the companies that manufacture sewing thread. These finishes are intended to increase the thread's ability to be sewn and to meet any particular functional need.

Anti-static

A specialized finish is applied to the thread to make it resistant to the accumulation of static charge.

Flame retardant finish

A finish of this kind is applied to the sewing thread to increase its flame resistance.

Water repellent finish

A hydrophobic finish is applied to make the thread water-repellent, which is then used to construct water-resistant seams.

Some Properties of Sewing Thread

- Possess a high tensile strength, so the seam doesn't come undone even after many pieces of washing. The tensile strength ought to be greater than the fabric so that the seams don't burst under the strain of the stretch. There would be less thread breakage, too, which is always a plus when sewing.

- Minimum friction between needle and thread while sewing quickly is achieved by using a line with a smooth surface and no irregularities.

- Threads with a higher initial modulus will flex less under stress loads encountered when sewing. The sewing thread should be relatively firm for the loops to be formed in the stitching process.

- The uniform diameter of the sewing thread makes it easy to thread the needle and glide through the cloth. Because of this, the line is less likely to jiggle as it's being processed.

- Using a shade-matching cabinet as a viewing background minimizes metamerism. The color phenomenon known as metamerism occurs when the same thread color seems to be different under various lighting.

- With high elasticity, the thread may quickly return to its standard length once the stress is removed. It must match the type of fabric you're sewing. Thus knits and wolves have distinct specifications. In addition, it has a significant impact on the durability and quality of the seam.

- A higher abrasion resistance improves the thread's stitching ability and makes it more durable to retain its physical qualities even after the tension has been released. The best abrasion resistance may be found in nylon and polyester.

- Stronger resistance to chemicals, as the thread is often washed, bleached, dry cleaned, and exposed to other chemicals.

Conclusion

The thread used makes all the difference when it comes to a seam's aesthetics and durability. In particular, the choice of sewing thread significantly impacts the final product quality of a garment.

The outward look and quality of the seam are affected by factors such as the structure of the sewing thread, the fiber types in the line, the finishing substance in the thread, etc.

So, are you looking for some excellent sewing thread? Ping us to get the best sewing thread and accessories. We are waiting with some exciting collection for you!

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.