Synthetic yarns play an important role in the fabric manufacturing. Whether for sportswear, or fashion apparel, the right yarn can make or break a fabric's performance. The three most commonly used polyester yarns are DTY (Draw Textured Yarn), FDY (Fully Drawn Yarn), and ATY (Air Textured Yarn). Each type has unique properties that determine its best use. Let's discuss the specifics and compare DTY, FDY, and ATY.

Table Of Contents

DTY vs FDY vs ATY

|

Feature |

DTY (Draw Textured Yarn) |

FDY (Fully Drawn Yarn) |

ATY (Air Textured Yarn) |

|

Texture |

Soft, crimped |

Smooth, glossy |

Cotton-like, fluffy |

|

Elasticity |

High |

Low |

Moderate |

|

Strength |

Medium |

High |

Medium |

|

Appearance |

Matte/Semi-dull |

Glossy |

Dull, natural look |

|

Common Uses |

Stretchable fabrics, home textiles |

Silk-like textiles, lingerie |

Outdoor fabrics, upholstery |

Which Yarn Should You Choose?

- Need stretch and comfort? → Go for DTY (best for activewear and home textiles).

- Want a glossy, silky finish? → Choose FDY (perfect for luxurious fabrics).

- Looking for a cotton-like feel? → Pick ATY (ideal for upholstery and durable applications).

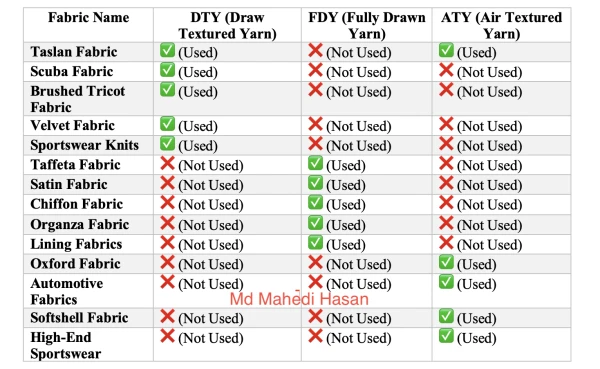

Figure: Types of Yarn used in Different Types of Fabric

Figure: Types of Yarn used in Different Types of Fabric

Fabrics Made from DTY:

- Taslan Fabric – Uses DTY & ATY

- Scuba Fabric – Uses DTY

- Brushed Tricot Fabric – Uses DTY

- Velvet Fabric – Uses DTY

- Sportswear Knitted Fabrics – Use DTY

Fabrics Made from FDY:

- Taffeta Fabric – Uses FDY

- Satin Fabric – Uses FDY

- Chiffon Fabric – Uses FDY

- Organza Fabric – Uses FDY

- Shiny Woven Fabrics (Lining Fabrics, Umbrellas, Flags) – Use FDY

Fabrics Made from ATY:

- Taslan Fabric – Uses ATY & DTY

- Oxford Fabric – Uses ATY

- Upholstery & Automotive Fabrics – Use ATY

- Softshell Fabric – Uses ATY

- High-End Sportswear Fabrics – Use ATY

DTY (Draw Textured Yarn)

DTY stands for Drawn Textured Yarn. It is a type of yarn twisted and drawn to create a textured appearance. It is often made from polyester chips. DTY is used in various applications, including clothing, home furnishings, seat covers, and bags. It is also used in sportswear, activewear, and technical uses. DTY is known for its elasticity, wrinkle resistance, and soft feel.

Types

DTY can be semi-dull, bright, or trilobal bright. It can also be made with different combinations of intermingle points.

Common DTY Denier Filament Options:

- 50D/36F – Very fine, soft for luxury textiles

- 75D/72F – Balance of softness and durability (sportswear)

- 150D/48F – Medium weight (curtains, upholstery)

- 300D/96F – Heavy-duty applications (bags, industrial use)

DTY Manufacturing Process

DTY is produced by twisting and texturing partially oriented yarn (POY). It is processed through a texturing process by using heat and mechanical processes. This creates a yarn with crimped and elastic properties. This process involves stretching, twisting, and texturing the yarn. The texturizing process gives DTY bulk and stretch properties.

Characteristics of DTY

- Texture: Soft, slightly fluffy, and elastic.

- Elasticity: High stretchability, making it perfect for flexible applications.

- Appearance: Matte or semi-dull, depending on the raw material used.

- Strength: Moderate but sufficient for most apparel applications.

- Common Denier Filament Options: 50D/36F, 75D/72F, 150D/48F, 300D/96F.

Best Uses of DTY

✔ Sportswear & Activewear (leggings, yoga pants).

✔ Home textiles (bedsheets, curtains, cushions).

✔ Stretch fabrics for fashion & casual wear.

✔ Automotive upholstery (car seats, headliners).

FDY (Fully Drawn Yarn)

FDY stands for Fully Drawn Yarn. It is a type of synthetic yarn that is fully stretched and used to make strong fabrics and textiles. It is a multi-filament yarn.

FDY Manufacturing Process

FDY uses a high-speed spinning process in which the yarn is drawn fully and wound onto cones without additional texturing. This process stabilizes the yarn through molecular orientation and crystallization. FDY is similar to POY (pre-oriented yarn), but it is fully oriented and has a lower remaining elongation.

Common Denier Filament Options:

- 40D/24F – Fine, silky texture for sheer fabrics

- 75D/36F – Slightly thicker, used in woven applications

- 150D/48F – Strong and smooth for upholstery

- 300D/96F – Used in industrial applications

Characteristics of FDY

- Texture: Smooth, glossy, and silky.

- Elasticity: Low; lacks the stretchability of DTY.

- Appearance: Glossy or semi-glossy.

- Strength: High tensile strength, making it durable.

- Common Denier Filament Options: 40D/24F, 75D/36F, 150D/48F, 300D/96F.

Best Uses of FDY

✔ Silk-like fabrics (sarees, chiffon, blouses).

✔ High-quality woven textiles.

✔ Lingerie & undergarments.

✔ Satin and glossy apparel fabrics.

ATY (Air Textured Yarn)

ATY is an acronym for Air Textured Yarn. It is a type of yarn that's used in many fabrics. ATY is also known as spun-like yarn.

Common Denier Filament Options:

- 75D/72F – Soft and lightweight

- 150D/96F – Medium weight, widely used

- 300D/192F – Heavy-duty applications

ATY Manufacturing Process

ATY is made from partially oriented yarn (POY). It is made by air-jet texturing of filament yarns.

Flat yarns are transformed into ATY using an air-texturing process that gives the yarn a hairy texture. High-pressure air creates loops and crimps, making the yarn look and feel like natural fibers such as cotton or wool.

Characteristics of ATY

- Texture: Cotton-like, with a natural hand feel.

- Elasticity: Moderate; does not stretch like DTY but has better bulkiness.

- Appearance: Dull, resembling natural fiber.

- Strength: Medium, but softer than FDY and DTY.

- Common Denier Filament Options: 75D/72F, 150D/96F, 300D/192F.

Best Uses of ATY

✔ Outdoor fabrics (awnings, tents).

✔ Automotive textiles (seat covers, headrests).

✔ Upholstery and heavy-duty furniture fabrics.

✔ Sportswear and breathable clothing.

Conclusion

DTY, FDY, and ATY each have unique properties that serve different textile applications.

- DTY offers elasticity.

- FDY brings smoothness and strength.

- ATY provides a natural, cotton-like feel.

Choosing the right yarn depends on the desired fabric texture, stretchability, and end-use application.

FAQs

1. Which is the softest yarn among DTY, FDY, and ATY?

ATY is the softest with air-textured loops. It gives a cotton-like feel.

2. Can FDY be used for making stretchable fabrics?

No, FDY lacks elasticity. If you need stretch, DTY is the better option.

3. What is the most durable yarn among the three?

FDY is the most durable due to its high tensile strength, making it ideal for woven fabrics.

4. Is DTY good for summer clothing?

Yes, DTY is breathable and lightweight, making it suitable for summer wear.

5. Which yarn is best for outdoor applications?

ATY is the best choice for outdoor fabrics. Cause of its durability and cotton-like texture.

.webp)

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.