Table Of Contents

What is tricot fabric?

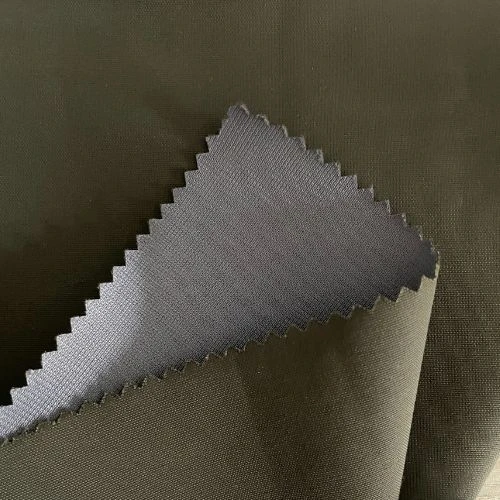

Tricot is a woven-like warp-knitted fabric with a tight texture on both sides. Warp-knitted tricot is produced by forming loops in the warp direction which makes tricot fabric look like woven fabric. The word Tricot is derived from the French word ‘tricoter' (in pronunciation the-ko), which refers to knit.

Tricot fabric is used to produce special clothing such as underwear, sportswear, and lingerie products. It has a unique weave that makes it smooth on one side while sporting texture on the other.

In this article, we will discover some basic facts about tricot fabric, what is made of, and what material is used, and so on.

Tricot Fabric Types

Heavy Weight Back Brushed Tricot:

Normally it is a wrapped knitted fabric with a texturizing effect on the back which is passed on to the brushing rollers in the finishing stage, raising a nap or strabs produces a fuzzy or downy surface. That's why brushed back tricot has a very good soft hand feel. This kind of tricot comes with a heavy weight between 180 and 250 GSM. Heavy-weight brushed tricot fabric is widely used in making tracksuits, trousers, shorts, and sports jackets. That's why brushed fabrics have a softer feel.

This novelty of inside brush textured tricot is good to use in the automotive industry.

Lightweight Back BrushedTricot:

This kind of tricot fabric is lightweight around 100 - 130 GSM and meant for liner and lining materials. Inside brushed Tricot offers numerous advantages including lightweight and soft hand feel. Lightweight brushed-back tricot fabric is widely used in pocketing.

Inside Brush Lightweight Tricot is Use as Lining - Light GSM.

Non-Brush Stretchy Tricot:

Non-brush Tricot is mostly made of poly/spandex and nylon/spandex. Usually, non-brushed tricot has a higher percentage of spandex to make it stretchy and suitable for sportswear and activewear. The weight varies from 170 to 240 GSM. This kind of tricot is more expensive than others but offers a great deal of advantages in terms of softness, stretchability, and other functionalities including UV protection and quick dry.

What is Tricot Fabric Made of?

Tricot fabric is a special warp-knit fabric made from filament yarn with a close inelastic knit. It’s made with fine or single yarns. Tricots could be produced from natural and synthetic fibres. Tricot fabric is made from a combination of fibres and fiber blends. Often it is produced from a blend of natural and synthetic fabrics.

Tricot fabric is commonly made from synthetic fibres such as acetate, nylon, polyester, and tri-acetate. Though the base fiber is mixed up for stability and flexibility, with nylon and spandex, respectively. Elastane could be mixed in the fiber blend to add stretch. Natural fibers such as cotton, wool, and silk are less preferable. But Tricot could produce a natural fiber blend with other synthetic materials to create wonderful tricot fabrics.

How is Tricot manufactured?

Tricot is a special plain warp-knit fabric. It is produced with a close-knit design, with the fibers running lengthwise. It forms vertical whales on the surface and crosswise ribs on the back of the fabric. Its unique zigzag weave texture allows the fabric to be very comfortable and soft for innerwear. These tricot productions are executed in the tricot knitting machine. This tricot knitting process produces a soft and flexible fabric that doesn’t snag or run easily.

In the tricot knit, two parallel lines of yarn are interloped. As the loops have been formed in roughly the warp direction. That produces a lightweight run-resistant tricot with a remarkable amount of stretch. This special method of construction ultimately creates a tricot fabric with several unique characteristics.

Tricot Fabric Characteristics

- Strong and lightweight.

- Makes light fabric weighing less than 4 ounces per square yard.

- Renowned for being a stable textile.

- Soft, wrinkle-resistant, and has good drapability.

- Doesn’t unravel or ladder, it’s normally stretchy and comfortable.

- Used for a wide variety of fabric designs and weights.

- Very low-cost fabric due to its production strategies.

- Tricot knitting technology is more practical that can be made with different sizes, shapes, and patterns.

- Stable in shape, no need for any special treatment.

- The manufacturer could be using different thicknesses of yarn. Through tricot, weft insertion machines to form simple patterns alternate and different styles of eyelet texture.

- High production efficiency about 98%

- The highest production speed could reach 3600rpm and the fabric width 210 inches.

- Good property to avoid loops knocking over and straggling.

- Using different constructions reduces the knocking-over phenomenon caused by yarn breaking and holes.

- Smaller extension compared with weft fabric.

- Doesn’t build up a static charge or cling to the body. Therefore, tricot-made apparel ensured comfortability to the wearer. such as Underwear, pantyhose, seamless tights, and gloves could be produced with tricot fabric.

Tricot Fabric Uses:

Tricots are made with different fibres including a blend of synthetic and natural. Therefore, it has countless options for apparel made with tricots. Tricot warp knitted construction and close-knit, provide a sturdy fabric property, hard-wearing, though comfortable to handle. It’s helpful to produce closely fitting comfort stretch items, such as

- Sportswear, swimwear, lingerie, inner garments, and even some special types of outerwear.

- Combination with its stability and stretch makes the tricot the best choice for backing fabrics for different kinds of laminate fabrics, lining, and pocketing.

- Tricot fabrics came with a good level of day-to-day wear and tear during any activity. This makes tricot a unique fabric for close-fitting comfort stretch clothing, such as different undergarments as well as outerwear.

- Comes in a variety of colours and patterns. Comforting finishes and supportive tricots make them a good choice for use in the making of lingerie and underwear, especially for women.

Dimensionally stable and not running. Consequently, it has numerous industrial applications, including base material for coating and laminating, automotive seating, and so on.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.