Let’s cut through the fluff—400T Taffeta fabric isn’t some mysterious textile from a luxury catalog. It's a high-density woven fabric, mostly made of polyester or nylon, widely used in outdoor gear, linings, jackets, tents, and more.

|

Category |

Details |

|

Also Known As |

High-density Taffeta, 400 Thread Count Taffeta, Lightweight Ripstop Taffeta |

|

Manufacturing Process |

Woven using plain weave on water-jet or air-jet looms, followed by heat setting & coating |

|

Appearance |

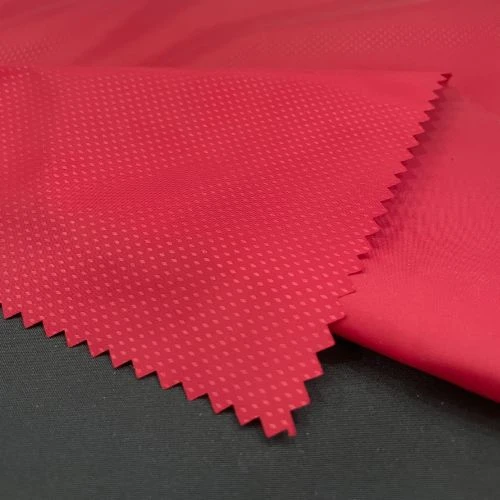

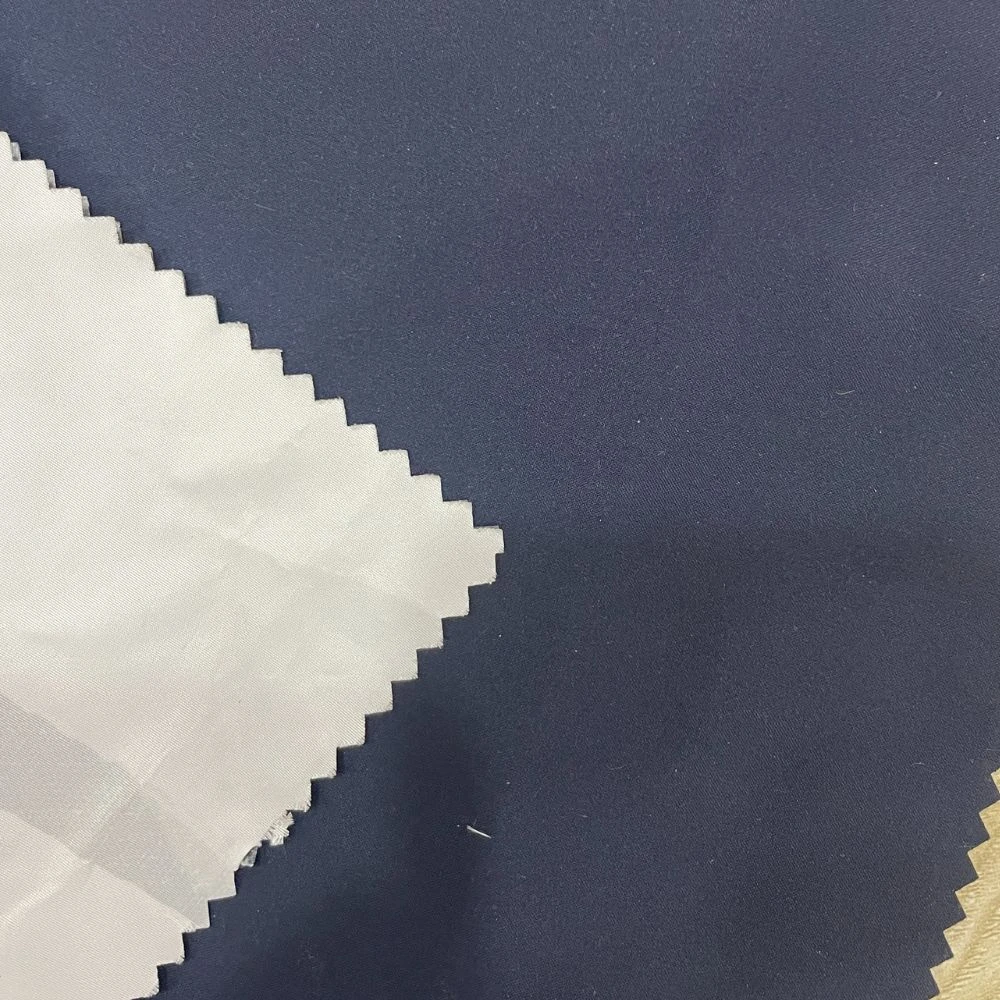

Smooth, crisp, semi-gloss or matte finish |

|

GSM Range |

35–55 GSM |

|

Composition Range |

100% Polyester / 100% Nylon |

|

Construction Range |

20D×20D, 30D×30D, 40D×40D; 400 Threads/Inch |

|

Functionality (Finish Options) |

PU, TPU, AC, W/R (Water Repellent), PVC, PV, IR Coating, FR (Flame Retardant), UV Resistant |

|

Possible Yarn Count |

20D/1, 30D/1, 40D/1 (both in warp and weft) |

|

Full Widths Available |

57/58", 59/60", 71/73" |

|

Fabric Breathability |

Low to Moderate (depends on coating) |

|

Stretchability |

Low (non-stretch); can be laminated with spandex backing if required |

|

Prone to Pilling/Bubbling |

Low (especially after heat-setting and with PU coating) |

|

Country of Origin (First Produced) |

Japan, circa 1965 (originated during high-density weave innovation for synthetic fibers) |

|

Biggest Exporter Country |

China – Over 5,000+ tons/year exported globally (as per 2023 customs data) |

|

Recommended Washing Temperatures |

Cold to 30°C (avoid hot water for coated variants) |

|

Finishing Uses to Increase Functionality |

Heat-setting, calendaring, anti-static, flame-retardant, antimicrobial, UV-resist |

|

Coating Thickness Range |

0.015 mm – 0.04 mm (depending on intended waterproofing level) |

|

Air Permeability Rate |

<5 cm³/cm²/sec (for PU-coated) |

|

Water Column Resistance |

800 mm – 3000 mm (with TPU or PU coatings) |

|

Tear Strength (ASTM D2261) |

2.5–4.5 N (depending on yarn and coating) |

|

Abrasion Resistance (Martindale) |

10,000 – 20,000 cycles (varies with coating and yarn) |

|

UV Resistance (ASTM G154) |

Up to 400 hrs with UV coating |

|

Shrinkage Rate |

<2% after washing when heat-set |

|

Color Fastness to Washing |

4–5 Grade (ISO 105-C06 standard) |

|

Applications |

Jackets, sleeping bags, tent linings, kites, car covers, umbrellas, backpacks, down-proof linings |

|

Sustainability Consideration |

Available in recycled polyester (rPET) and bio-based nylon variants |

|

Storage Tips |

Store rolled, away from sunlight and moisture; avoid sharp folds to prevent crease marks |

The “400T” stands for 400 threads per square inch, combining warp and weft. That’s dense. We’re talking about a fabric that doesn’t just look sleek but holds up under pressure—literally.

Table Of Contents

Construction Details of 400T Taffeta

What Does “400T” Really Mean?

Think of it like counting the grains of sugar in your tea. 400T = 400 threads per square inch. Higher thread count = tighter weave = better performance. You’ll find:

- Warp threads: Typically 200

- Weft threads: Typically 200

This means fewer pinholes, better barrier properties, and stronger fabric integrity.

Common Yarn Count Used

The standard yarns used in 400T Taffeta range from:

- 20D to 40D (Denier)

- Occasionally 20D × 20D, or 30D × 30D

Lower deniers keep it light and thin, which is great for windbreakers or tent linings.

Key Technical Specifications

|

Property |

400T Taffeta Value |

|

GSM Range |

35–55 GSM |

|

Thread Count |

400 per square inch |

|

Yarn Size |

20D, 30D, 40D |

|

Composition |

100% Polyester or Nylon |

|

Construction Type |

Plain weave |

|

Common Coatings |

PU, TPU, AC, PVC, W/R (Water Repellent) |

|

Width Options |

57/58", 59/60", 71/73" |

|

Stretchability |

Low (Non-stretch) |

|

Breathability |

Moderate to Low |

|

Pilling Resistance |

High (especially in coated versions) |

Where Is 400T Taffeta Fabric Used?

This is the kind of fabric that doesn't just sit pretty. It works.

Fashion Industry

- Jacket linings

- Raincoats

- Lightweight sportswear

It's water-resistant, crisp, and rustles just right. That "swish-swish" sound? That's taffeta drama.

Outdoor Gear

- Tent walls and flysheets

- Sleeping bag linings

- Waterproof backpack covers

Thanks to TPU or PU coatings, 400T Taffeta can resist water up to 2,000 mm Hâ‚‚O or more—basically rainproof.

Home Textiles

- Umbrellas

- Shower curtains

- Decorative pillow covers

Because it’s shiny and smooth, it adds a touch of sophistication even in low-cost home décor.

Functionality Add-Ons

Not all 400T Taffeta is created equal. A lot depends on its finish.

Coating Types and Their Uses

- PU Coated: Makes it waterproof, still breathable

- TPU Coated: Offers elasticity + water resistance

- PVC Coated: For heavier-duty waterproofing (less breathable)

- AC Coated: For anti-static or UV resistance

- W/R (Water Repellent): Protects against light rain

Think of these like software upgrades—you add what you need based on the job the fabric has to do.

Color Options & Finish

- Dyed with disperse dyes (for polyester)

- Glossy, matte, or dull finish

- Heat-set for dimensional stability

Why Choose 400T Taffeta?

Let’s be honest. You could go for a 190T or 210T fabric. It’s cheaper. But if you’re looking for durability with lightness, 400T is a sweet spot.

Pros

- High tear strength

- Lightweight (important for packable gear)

- Water and wind resistant

- No pilling

- Compact and foldable

Cons

- Not very breathable

- Less flexible unless blended

- Slightly noisy when moving

Still, it gets the job done. And more.

Market Stats & Use Cases

Here’s where numbers speak louder than adjectives.

- Global use: 400T Taffeta makes up 18% of high-density fabric sales in Asia.

- Export volume: China exports over 5,000 tons/year of 400T taffeta alone.

- Price range: Between $0.60–$1.20/meter, depending on coating and yarn quality.

That’s a solid return for a versatile material.

How to Choose the Right 400T Taffeta?

For Jackets & Apparel

Opt for:

- 100% polyester

- 20D × 20D yarn

- PU or W/R coating

For Outdoor Use

Go for:

- Nylon version

- TPU coating

- GSM above 45 for added strength

For Decor Use

Pick:

- Matte finish

- AC coating for colorfastness

Always ask for lab test results—especially for water resistance, colorfastness, and GSM.

Conclusion: The Real Deal With 400T Taffeta Fabric

You don’t need to be a textile engineer (though I happen to be one) to appreciate 400T Taffeta fabric. It’s functional, sleek, and widely trusted in industries that demand performance and durability. Whether you’re manufacturing outerwear, sewing tents, or lining bags, this fabric holds its own.

No bells. No whistles. Just pure fabric power, woven tight and built to last.

FAQs

Q1. Is 400T Taffeta better than 210T Taffeta?

Yes. 400T is denser, more durable, and usually performs better under tension and wear.

Q2. What’s the best coating for waterproof 400T Taffeta?

TPU or PU coatings are best. TPU is more elastic and durable, while PU is cost-effective and breathable.

Q3. Can 400T Taffeta be used for sleeping bags?

Absolutely. Its smooth surface, light weight, and moisture resistance make it ideal.

Q4. Is 400T Taffeta breathable?

It’s moderately breathable, especially with PU coating. However, it’s not as breathable as cotton or mesh fabrics.

Q5. Can I dye 400T Taffeta at home?

Not easily. It requires dispersed dyes and high-temperature dyeing, which is best left to professionals.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.