Textile Suppliers have been receiving lots of inquiries about ‘ taffeta fabric ’ every day. Here, the following article will give a quick summary of taffeta fabric that will help you select the right taffeta fabric to make your favorite clothing and outdoor gear including your coats, jackets, bags, and tents.

Table Of Contents

What Is Taffeta Fabric?

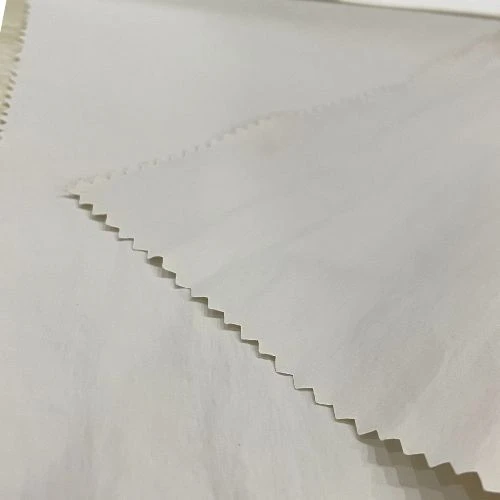

Taffeta is a crisp, smooth, lightweight, shiny, plain/twill-woven fabric. It is also known as Paper Taffeta and Shot-Silk. Although earlier taffeta was made of silk, it is now mostly made of synthetic fiber, particularly polyester and nylon FDY filament. Taffeta is the ideal fabric for creating high-fashion outerwear, particularly jackets. It is ultimately used to create beautiful men's and women's jackets, coats, raincoats, gowns, bags, tents, and curtains.

For a better understanding, you can watch the video of our expert Jahirul Islam.

Types of Taffeta:

Taffeta can also be categorized based on thread density per square inch as follows

- 190T Taffeta

- 210T Taffeta

- 230T Taffeta

- 290T Taffeta

- 300T Taffeta

- 320T Taffeta

- 350T Taffeta

- 380T Taffeta

- 400T Taffeta

- 410T Taffeta

- 430T Taffeta

There are three most common types of taffeta based on their end-use in the garments. They are as below.

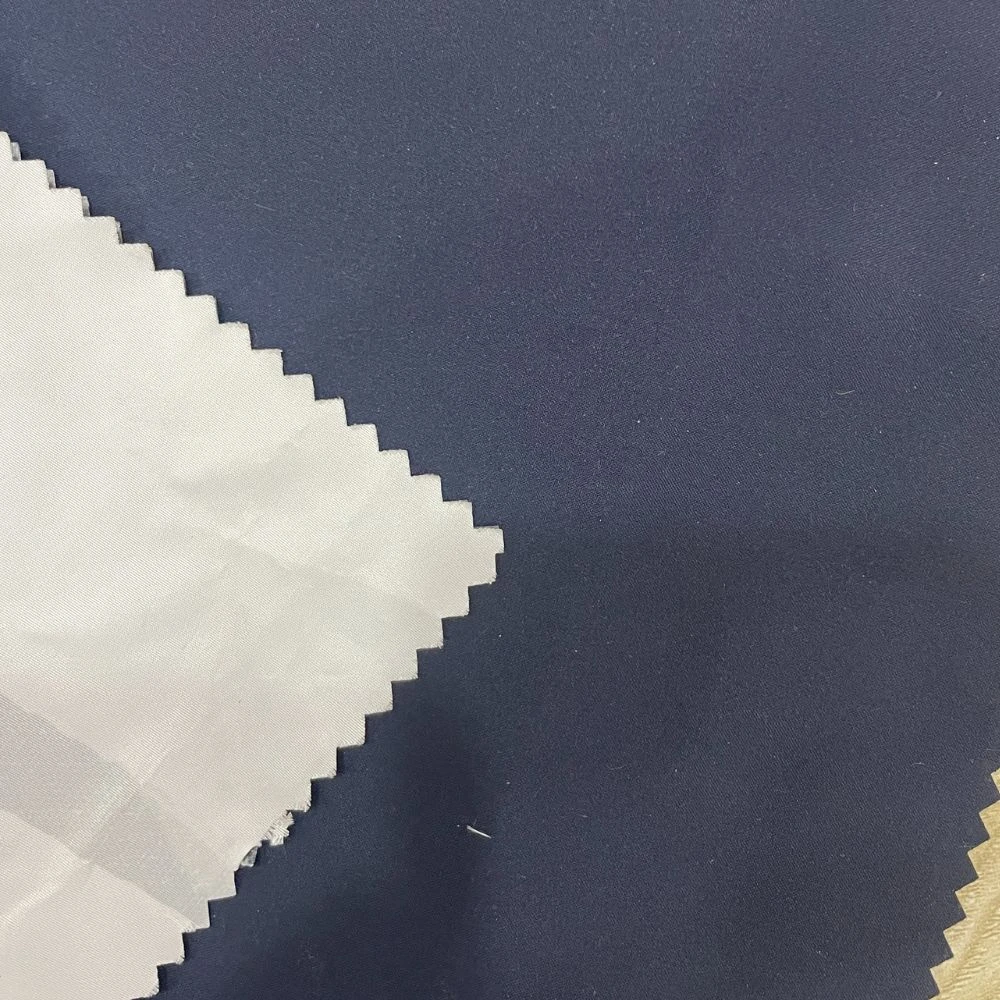

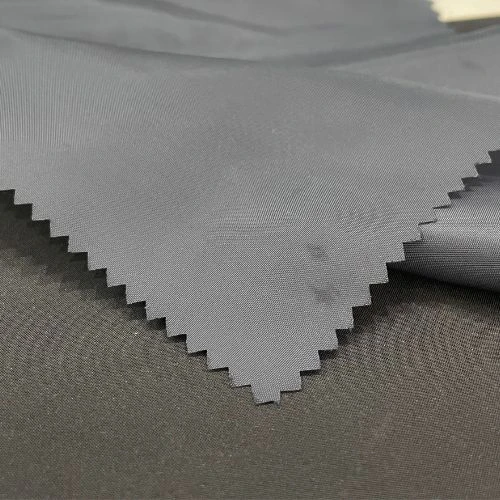

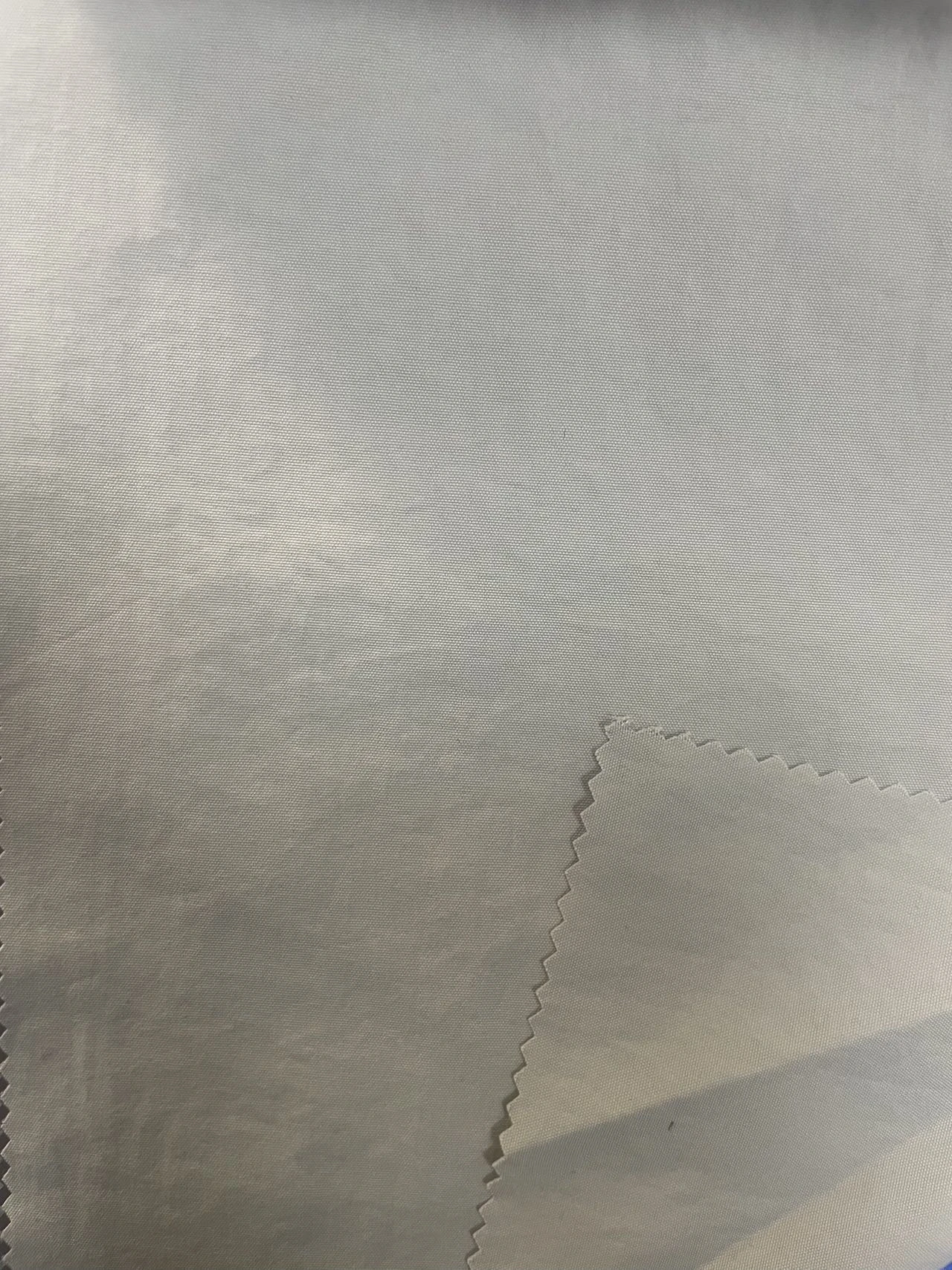

a. Lining Taffeta

Lining taffeta is usually used as lining inside the garments to support the shell or main body fabric. The taffeta used in the lining often has a low density and GSM. The three most common lining taffetas are 190T, 210T, and 230T with GSM between 52 and 65. Here, "T" indicates the number of threads in warp and weft per square inch. The higher the number of "T", the denser the taffeta is. And the yarn count varies from 60D to 65D.

b. Pocketing Taffeta

Pocketing taffeta is very similar to lining taffeta. As the name suggests, this kind of taffeta is used as pocketing fabric. Sometimes pocketing taffeta is lighter than the lining, sometimes higher, depending on your requirements. The most common pocketing taffetas are 170T, 180T,190T, 210T, 220T, and 230T with GSM between 50 and 65.

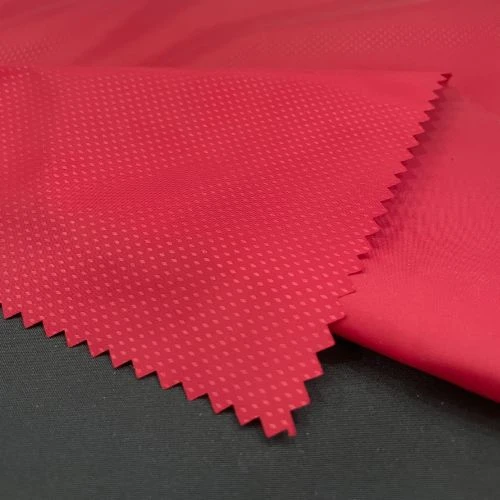

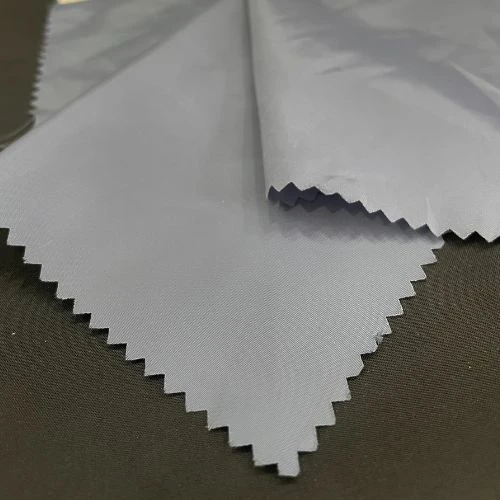

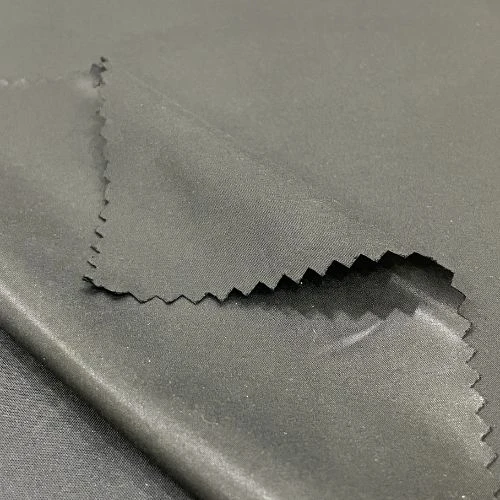

c. Shell/Main Body Taffeta

Unlike lining and pocketing taffeta, shell taffeta is used as the main body fabric. Shell taffeta is often of higher density, starting from 300T to 450T. The two most common shell taffetas are 300T Taffeta Fabric and 380T Taffeta Fabric. And shell taffeta GSM varies between 35 to 70. Shell taffeta is made with high thread density so that the down or padding used inside cannot come out. Most of the time, it's finished with different coating materials like AC, PU, PVC, PA, and Cire to make it waterproof and down-proof.

Based on raw materials, there are mainly three types of taffeta as below

- Silk Taffeta

- Polyester Tafetta

- Nylon Tafetta

Taffeta can be classified into many categories depending on its structure. They are as below

- Plain Taffeta

- Twill Taffeta

There are also some other kinds of taffeta found on the market

- Paper Taffeta

- Crinkle Taffeta

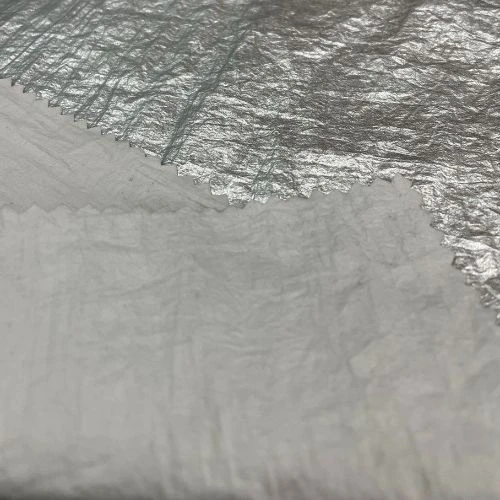

- Foil Coated Taffeta

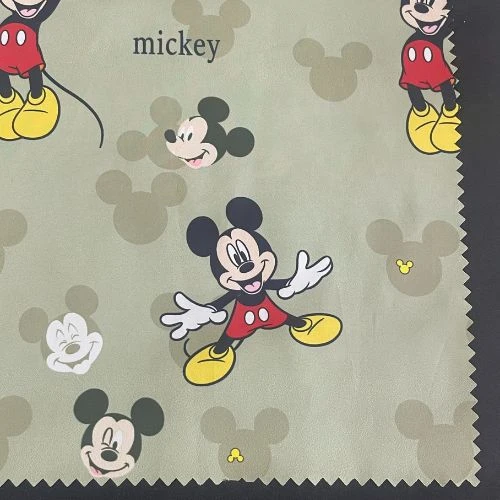

- Printed Taffeta

- Solid Dyed Taffeta

- Embossed Taffeta

How is taffeta made?

The word “Taffeta” is derived from the Persian word, which means "twisted woven.” It is made by twisting silk, polyester, or nylon yarn. Originally, taffeta was made from silk. However, in the twentieth century, semi-synthetic fibers were used to make it. Now, man-made fibers such as nylon, rayon, and acetate are used in the taffeta manufacturing process.

Taffeta fabrics are made using a tightly woven called ‘plain-weave’ technique. It is also known as ‘tabby weave’, with very fine horizontal ribs. This technique has a single weft thread going over and under a single warp thread. The simple criss-cross pattern resembles a checkerboard. Then it creates a checkerboard pattern. Weaving twisted threads create the stiffness and structure of the fabric, which makes taffeta unique fabric.

Flowchart of Taffeta Manufacturing:

- Production of Monomer Alcohol: Ethyl, which is extracted from petroleum oil is reacted with dimethyl terephthalate at a high temperature to produce monomer alcohol.

- Production of Polyester: This monomer is then combined with terephthalic acid to produce the polymer known as polyester.

- Extrusion: This molten substance is then extruded through a slot and allowed to cool into the long ribbons.

- Chipping: These ribbons are then chipped; they are melted again.

- Spinning: Next, this molten polyester is extruded through a spinneret.

- Drawing: The resulting strands of textile fiber are allowed to cool bare before they are stretched.

- Finishing: Lastly, the drawn polyester fibers are dyed or subjected to flame-retardant or anti-static treatments.

- Weaving: Once the raw textile fiber is acquired, taffeta fabric can be formed with either hand weaving or an industrial weaving machine.

Key grey specifications of Taffeta

|

Characteristics |

Properties |

|

i. Warp Count |

15D/20D/30D/40D/50D/ 58D/63D/68D/70D Polyester and Nylon |

|

ii. Weft Count |

15D/20D/30D/40D/50D/ 58D/63D/68D/70D Polyester and Nylon |

|

iii. Width |

60", 63", 67", 71" up to 120” |

|

iv. Density: |

170T/ 180T/ 190T/ 200T/ 210T/ 220T/ 230T/ 240T/ 290T/300T/320T/360T/380T/400T/420T |

|

v. GSM |

35, 50, 55,60, 65,70,80 |

Taffeta Characteristics:

|

Characteristics |

Properties |

|

1. Fabric composition: |

Polyester, Nylon, Silk |

|

2. Fabric breathability: |

Very breathable |

|

3. Moisture-wicking abilities: |

Very good |

|

4. Stretchability: |

Low |

|

5. Prone to pilling/ bubbling: |

None |

|

6. Heat retention abilities: |

Low |

|

7. Other Characteristics: |

Crisp, shimmery, Smooth, produce ‘scroop’ sounds, etc. |

Advantages of Taffeta

- Luxurious: Taffeta is a crisp, shimmery, smooth fabric that has created many iconic looks. The sheen shimmer comes from silk or rayon which is the fiber used to make taffeta.

- Pliable: Taffeta is a stiff fabric. It can create a beautiful, structural silhouette. Taffeta never loses its shape over time. It doesn’t pill and maintains its smooth surface.

- No Pilling: In every fabric, protruding fibers emerge on the surface of the fabric with the time passage. It's called the pilling of the fabric. In the case of taffeta fabric, no pills will arise on its surface.

- Coating: It can be made with various coatings. Such as PA, PUL, PVC, silver, milky coating, waterproof, water repellent affection, etc.

Disadvantages of Taffeta

- Hard to work with.

- Taffeta is slippery and could be hard to maneuver with a sewing machine.

- Need pre-washing fabric to make it softer

- Every time has to use a sharp needle.

- Is very expensive.

- Not breathable.

- Always having stiffness.

- Doesn't have much stretch and flexibility.

- Snag easily and create pulls.

- Prone to creasing.

- Requires more maintenance, and so on.

Application of Taffeta:

- Home Decoration: curtains, insulation, sleeping bags, and used for wallpaper.

- Gowns: wedding gowns, party attire, and fashionable dresses.

- Undergarments: corsets, evening wear, blouses, and lingerie.

- Technical Clothing: parachutes, protective coveralls, medical gowns, and other hospital purposes.

Especially outerwear jackets: rainwear, waterproof and windbreaker jacket, Fake down, and real down jacket

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.