Definition and Basic Structure

190T Pongee is a finely woven polyester fabric made of DTY filament yarn. Smooth, Thin, Lightweight. But tough as nails. You’ve likely touched it before — think umbrella linings, windbreaker jackets, or that rustle of a tent in the breeze.

|

Parameter |

Details |

|

Also Known As |

Polyester Pongee, 190T Polyester, Lightweight Lining Fabric |

|

Manufacturing Process |

Plain Weave, Warp and Weft Polyester Yarns, Dyeing, Finishing (Coating or Lamination as per use) |

|

Appearance |

Smooth, Slightly Glossy, Lightweight, Crisp Texture |

|

GSM Range |

60–85 GSM |

|

Composition Range |

100% Polyester (Common); Rarely with <5% Nylon or Viscose Blend |

|

Construction Range |

190 Threads per inch (TPI); Plain Weave (1:1) |

|

Functionality Options |

TPU Coated, PU Coated, AC Coated, W/R (Water Repellent), PVC Laminated, PA Coated |

|

Possible Yarn Count |

Warp: 75D/72F; Weft: 75D/72F or 50D/36F (depending on softness requirement) |

|

Full Width Options |

57/58”, 59/60” (most common); Wider versions available up to 71/73” for tent/furniture applications |

|

Fabric Breathability |

Low (unless modified with breathable coating like AC or microporous PU) |

|

Stretchability |

Very Low (Non-Stretch unless blended with spandex, which is rare) |

|

Prone to Pilling/Bubbling |

Low; Resistant to pilling and bubbling under normal use |

|

Country First Produced (with Year) |

Japan, Late 1950s (adapted during post-war polyester fabric development) |

|

Biggest Exporter Country |

China – Approx. 210,000+ tons/year (Used heavily in umbrella and tent industries globally) |

|

Recommended Washing Temp. |

30°C–40°C (Cold to warm water); Do not bleach; Tumble dry on low; Avoid high heat ironing |

|

Finishing Uses |

- PU/TPU Coating for waterproofing- AC Coating for breathability- WR Finish for water repellency- UV and Fire Retardant Treatments |

|

UV Resistance |

Moderate to High (Polyester has natural UV resistance, enhanced with UV stabilizers) |

|

Colorfastness |

Excellent (4–5 Grade, AATCC Standard) |

|

Shrinkage Resistance |

High (Dimensional stability due to polyester structure) |

|

Abrasion Resistance |

Moderate (Better with coatings like PU or TPU) |

|

Eco-Friendliness |

Not biodegradable; Recyclable polyester versions available |

|

Applications |

- Umbrellas- Tent Linings- Windbreakers- Sportswear Lining- Bags & Pouches- Car Covers- Raincoats |

Thread Count - What Does 190T Mean?

Here's where numbers matter. "190T" means 190 threads per square inch. A higher "T" usually means denser fabric. So, 190T sits in the sweet spot — not too dense, not too flimsy. Perfect for outdoor use and lightweight garments.

Table Of Contents

Characteristics of 190T Pongee Fabric

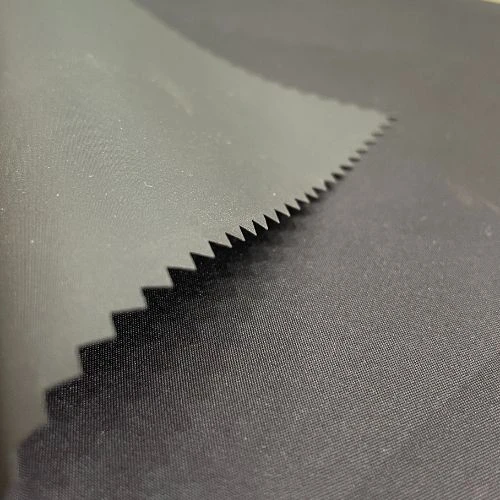

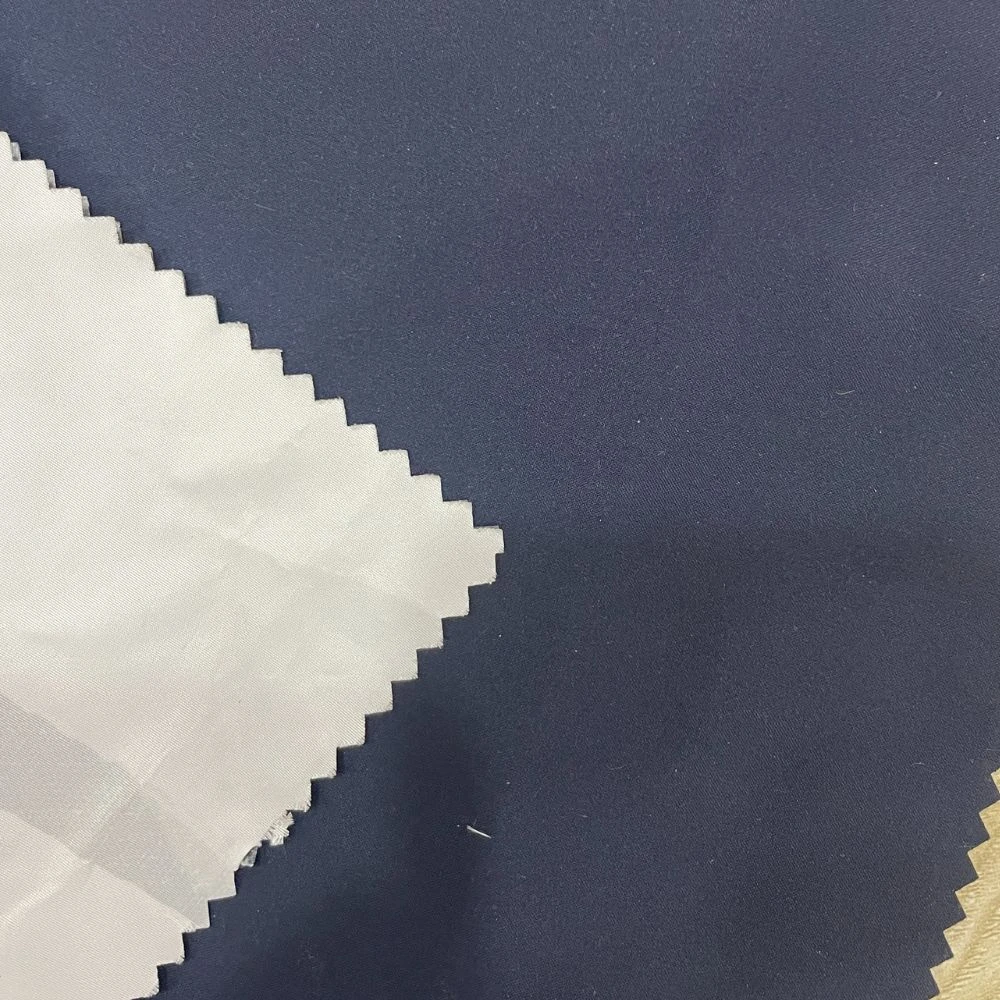

Texture and Appearance

This fabric has a slightly glossy surface. It’s not too shiny, just enough to look sleek. The touch? Smooth and slick — almost silk-like but with the performance of synthetic fiber.

Composition and Weight

Most 190T Pongee fabrics are made of 100% polyester. Some blends do exist, but polyester rules the roost. Why? It’s cheaper, weather-resistant, and holds color well.

GSM Range and Thickness

Typically, it ranges between 60 and 85 GSM (grams per square meter). That’s thin, yet functional. You won’t find it acting bulky. But don’t confuse lightweight with weak — this fabric can take a beating.

Functional Features

Waterproof and Windproof Qualities

It shines when treated with coatings. Apply a PU or PVC layer, and this baby becomes a rain shield. Add water-resistant finishes, and it blocks moisture like a champ. Wind? It slides right off. Not to mention, it dries super fast.

Durability and Tear Resistance

Don't judge it by weight. 190T Pongee can resist moderate abrasion and tearing. Its tight weave gives it strength. Great for gear that gets folded, stretched, or squished regularly — like bags and canopies.

Manufacturing Process of 190T Pongee Fabric

Weaving Technique

It’s woven using a plain weave technique — the simplest of all. But it works. Warp and weft yarns cross over one another at right angles. The result? A tight, balanced structure.

Dyeing and Finishing Process

This fabric takes dye like a sponge. That means vibrant colors that don’t fade fast. Depending on use, it might also go through finishing treatments:

- PU coating (for waterproofing)

- AC coating (for breathability)

- WR finish (for water repellency)

Common Applications of 190T Pongee Fabric

Use in Outdoor Products

Umbrellas, Tents, and Raincoats

Most umbrellas use 190T Pongee. Why? It repels water, dries quickly, and folds down neatly. Tents and raincoats also benefit from its low weight and solid protection. It’s a go-to for camping gear and weatherwear.

Everyday Apparel and Accessories

Linings, Windbreakers, and Bags

Inside jackets, in travel pouches, under thin coats — that’s 190T at work. Its slick surface makes it ideal for linings. You’ll also find it in foldable bags, budget backpacks, and promotional items.

Advantages and Disadvantages of 190T Pongee Fabric

Advantages You’ll Appreciate

- Lightweight and portable

- Affordable and easy to source

- Takes color well and stays vibrant

- Versatile: great for umbrellas, jackets, or gear

- Quick-drying and mold-resistant

Disadvantages You Should Know

- Not super breathable without coatings

- Can feel plasticky when untreated

- Limited stretch (non-elastic)

- Not as strong as heavier deniers like 210D or 420D

Conclusion: Is 190T Pongee Fabric Right for You?

If you need something light, cheap, weather-ready, and reliable, then yes — 190T Pongee is your friend. It’s not the fanciest fabric out there. But it’s practical, widely used, and works where it counts. Whether you’re sewing outdoor wear, crafting custom umbrellas, or just making affordable lining — this polyester champ has you covered.

FAQs About 190T Pongee Fabric

1. Is 190T Pongee fabric waterproof by default?

Not exactly. It needs a coating like PU or PVC to become waterproof. On its own, it resists water lightly but won’t handle heavy rain.

2. What’s the GSM of typical 190T Pongee?

It usually ranges from 60 to 85 GSM, depending on coating and finish.

3. Can I use 190T Pongee for sewing jackets?

Yes, especially for linings or lightweight windbreakers. Just don’t expect thermal insulation.

4. Is it more durable than nylon?

Polyester 190T is durable for its weight, but nylon is generally stronger. However, polyester resists UV better and is more affordable.

5. What coating options are available for 190T Pongee?

Common coatings include PU, PVC, PA (polyamide), and AC. You can also get it with WR (Water Repellent) treatments for extra weather resistance.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.