Ever wonder why some umbrellas feel smoother, some jackets lighter, yet stronger? That’s usually 350T Pongee fabric doing the magic. It’s a fine, plain-woven polyester or nylon fabric with a thread density of 350 threads per square inch—yep, that’s where the “350T” comes from. It feels soft but handles outdoor challenges like a champ.

|

Parameter |

Details |

|

Also Known As |

High-density pongee, 350T polyester pongee, Micro-pongee |

|

Manufacturing Process |

Weaving (Plain weave) → Scouring → Dyeing (Disperse) → Finishing → Coating (optional: PU, TPU, AC, PVC) |

|

Appearance |

Smooth, fine, matte or semi-gloss finish; tightly woven surface |

|

GSM Range |

90 – 120 GSM |

|

Composition Range |

100% Polyester (commonly), Blends with Nylon (optional) |

|

Construction Range |

350 threads/inch (e.g., 75D×75D or 100D×100D) |

|

Functionality (Post-Finishes) |

✅ TPU (Waterproof & Breathable) |

|

Possible Yarn Count |

75D/72F, 100D/144F (both filament-based) |

|

Full Width (Usable Width) |

57/58", 59/60" (occasionally 71/73" for coated variants) |

|

Fabric Breathability |

Moderate without coating; Low if PU/PVC coated |

|

Stretchability |

Non-stretch unless blended with spandex or crimped yarn |

|

Prone to Pilling/Bubbling |

Low pilling risk; bubbling possible with poor coating or excess heat exposure |

|

Country of Origin (Year) |

Japan, circa 1950s – First developed for lightweight kimonos and lining |

|

Biggest Exporter Country (2023) |

China – Over 65,000 tons/year exported globally |

|

Recommended Washing Temp |

30–40°C (hand or machine wash); avoid hot ironing (max 110°C) |

|

Finishing Uses to Enhance Functionality |

- Calendering (smooth finish) - Coating (PU/TPU for waterproofing) - Antistatic, UV, or FR treatment - Cire finishing (shiny look) |

|

Common Applications |

- Jacket linings - Windbreakers - Umbrellas - Bags/backpacks - Tent inner layers - Promotional products - Raincoats & ponchos |

|

Color Fastness to Light |

4–5 (Good) |

|

Abrasion Resistance |

Moderate to High (Martindale: ~20,000 cycles) |

|

Shrinkage (%) |

≤ 2% after washing (if pre-set properly) |

|

UV Resistance |

Good when UV-coated; standard polyester provides basic protection |

|

Flame Retardant (Optional) |

Achievable via FR coating for EN 531/ISO standards |

|

Cost Range (Wholesale) |

$0.80 – $1.50 per meter (varies by finish and MOQ) |

|

Dyeing Process |

High-temp disperse dyeing (suits polyester filaments) |

|

Print Compatibility |

Excellent for sublimation and pigment printing |

|

Sustainability Option |

Available in rPET (Recycled Polyester) versions |

Pongee fabrics have been around for decades, but the 350T version brings in tighter weaving, better durability, and a cleaner finish. Think of it as a step up from 210T or 190T—more refined and reliable.

Table Of Contents

Technical Specs and Composition

Thread Count Explained (Why 350T Matters)

The 350T simply means 350 threads are woven per inch of fabric. More threads = tighter weave = stronger fabric. Compared to a 190T or 210T pongee, 350T resists water, wind, and wear more effectively.

If 190T is your everyday sedan, 350T is the SUV with all-wheel drive. It just handles things better.

GSM Range of 350T Pongee

- Typical GSM: 90–120 GSM

That’s the sweet spot. It’s light enough for jackets and linings but dense enough for windbreakers and tents. Lower GSM = more breathable. Higher GSM = better insulation.

Yarn Types and Construction

Mostly made from 75D or 100D polyester filaments, occasionally blended with nylon for stretch or strength. Construction is usually:

- Plain weave

- Tight filaments

- Anti-fray edges (thanks to warp/weft balance)

Functional Characteristics

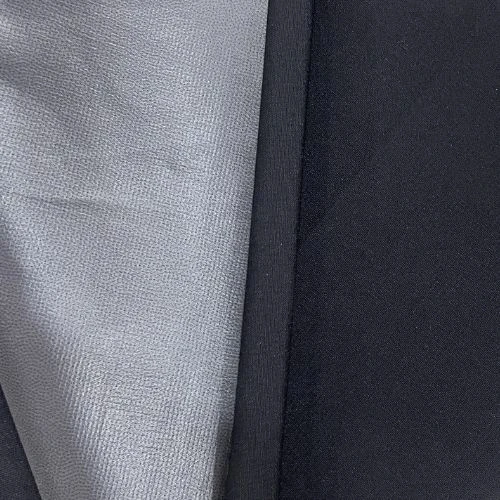

Waterproof Coatings (TPU, PU, AC, PVC)

350T Pongee is the go-to fabric for coatings like:

- TPU: Great for flexibility and waterproofing

- PU: Makes it more breathable and soft

- AC (Acrylic): Cheaper but less durable

- PVC: Adds stiffness and weather resistance

The base fabric gets laminated or dipped in these coatings. That’s how it turns into windproof, rainproof, or even UV-resistant versions.

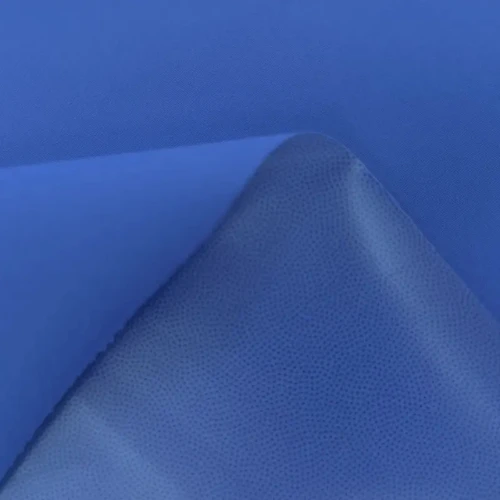

Fabric Width & Color Options

- Full Widths: Usually 57/58" or 59/60"

- Colors: From solid blacks and blues to camo and neon—suitable for everything from tents to totes.

The dyeing process uses disperse dyeing with high colorfastness (4.5 to 5).

Stretchability & Breathability

350T Pongee is non-stretch unless blended with spandex or crimped yarns. As for breathability, the tighter weave slightly reduces airflow. But that’s the trade-off for wind and water resistance.

If coated with PU or TPU, expect limited breathability but better waterproofing. Uncoated? Much more breathable.

Common Uses of 350T Pongee Fabric

Outdoor & Sports Applications

From raincoats to lightweight tents, 350T is often used because it’s:

- Water-resistant

- Rip-resistant

- Packable

It shows up in sportswear, ponchos, and camping hammocks. The military and trekking brands love it.

Everyday Fashion and Lining Use

Lining for jackets? Check. Inside bags and backpacks? Check. It's light, soft, and cost-effective—perfect for mass production.

Some travel jackets even use it as the outer shell with a TPU coating.

Promotional & Umbrella Fabric Market

Ever receive a branded umbrella that didn’t fall apart in the first storm? Probably 350T Pongee. This fabric holds its shape, prints well, and stays sleek for years. Ideal for:

- Umbrellas

- Parasol tops

- Banners and giveaways

Advantages and Drawbacks

What Makes It Popular

- Durability: Outlasts cotton linings or nylon taffeta

- Lightweight: Doesn’t bulk up your jacket or bag

- Water-resistant: Especially when coated

- Affordable: Cost-effective compared to nylon ripstop or Oxford

What You Should Watch Out For

- Low Breathability: Especially with thick coatings

- Not Biodegradable: It’s polyester-based

- Can Wrinkle: If not finished properly

Manufacturers sometimes try to pass off 280T or 300T Pongee Fabric as 350T. So always check the specs.

Conclusion

350T Pongee fabric sits at the sweet spot of performance and price. It's sleek enough for fashion, tough enough for outdoor gear, and cheap enough for bulk production. It doesn’t scream luxury, but it gets the job done—quietly and reliably.

Whether you're sewing jackets, sourcing umbrellas, or building your textile brand, understanding this fabric could save you a ton of time and money. Next time someone mentions "350T Pongee," you won’t just nod—you’ll know.

FAQs

1. Is 350T pongee better than 210T pongee?

Yes. 350T has a tighter weave, making it more durable, water-resistant, and windproof than 210T.

2. Can I dye 350T pongee fabric at home?

You can, but it's tricky. You'll need disperse dyes and high heat—definitely not a regular kitchen project.

3. Is 350T pongee waterproof without coating?

Not fully. It’s water-repellent to some extent but needs a TPU or PU coating to be truly waterproof.

4. What’s the price per meter of 350T pongee?

Usually ranges between $0.80–$1.50/meter depending on finish, coating, and quantity.

5. Can it be used for eco-friendly products?

Not naturally, since it's polyester-based. But using recycled polyester (rPET) versions makes it more sustainable.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.