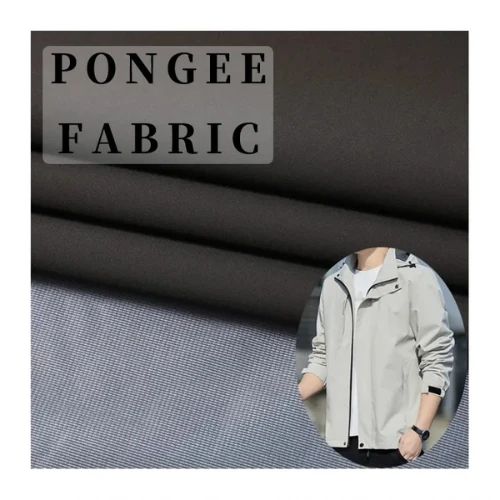

210T Pongee is a lightweight, smooth, tightly woven polyester fabric made of DTY Yarn. Pongee Fabric is often used for umbrellas, linings, and outdoor covers. The “210T” refers to the thread count per square inch—specifically, 210 threads. That high count gives the fabric a denser, more durable build compared to lower-T variants like 190T Pongee Fabric.

|

Category |

Details |

|

Also Known As |

210T Polyester Pongee, 210T Taffeta Pongee, Umbrella Fabric, Lining Pongee |

|

Manufacturing Process |

Woven (Plain weave), Continuous filament yarn, Jet dyeing, Coating (PU, AC, etc.) |

|

Appearance |

Smooth surface, semi-glossy, tightly woven, fine texture |

|

GSM Range |

56 – 70 GSM |

|

Composition Range |

100% Polyester (most common); blends rare |

|

Construction Range |

210 Threads per inch, Commonly 75D × 75D or 75D × 100D |

|

Functionality / Coating Options |

PU (Polyurethane), TPU (Thermoplastic Polyurethane), AC (Acrylic), WR (Water Repellent), PVC (Polyvinyl Chloride), PA (Polyamide) |

|

Possible Yarn Count |

75D, 100D polyester filament |

|

Full Widths |

57/58" |

|

Fabric Breathability |

Moderate to Low (depends on coating) |

|

Stretchability |

Non-stretch unless blended or mechanically finished |

|

Prone to Pilling/Bubbling |

Low (when coated); uncoated versions may show mild wear after prolonged use |

|

Country of Origin (Year) |

Japan, late 1960s – during the rise of synthetic fiber tech |

|

Biggest Exporter (Volume) |

China – Over 500 million meters/year exported globally |

|

Recommended Washing Temperature |

30°C – 40°C, gentle cycle, do not bleach, do not wring |

|

Finishing Options to Enhance |

UV coating, Anti-static finish, Flame-retardant (FR) treatment, Anti-bacterial coating, Silver coating for thermal control |

|

Water Resistance (Post Finish) |

Up to 5000 mm Hâ‚‚O with PU/TPU coating |

|

Tear Strength (ASTM D2261) |

Approx. 8–12 N (warp), 7–10 N (weft), depending on yarn size and coating |

|

Colorfastness to Light |

Grade 3–4 (on a scale of 5) |

|

Shrinkage Rate |

<2% (with proper heat setting and finishing) |

|

UV Protection (Post Finish) |

UPF 30–50+ depending on the finish |

|

Drying Time |

Fast-drying (due to polyester base) |

|

Ironing Instructions |

Low heat, preferably steam only |

|

Biodegradability |

Non-biodegradable (polyester base), but recyclable |

|

Applications |

Umbrellas, Tent Linings, Car Covers, Bag Linings, Promotional Banners, Raincoats, Windbreakers, Flags, Paragliding Equipment |

|

Pricing Range (Bulk FOB) |

$0.35 – $0.65 USD per yard (depending on GSM, coating, MOQ, country) |

|

MOQ in B2B Market |

1000–3000 meters (varies by supplier and finish) |

|

Lead Time (Bulk Production) |

10–25 days depending on order volume and finishing |

Table Of Contents

Key Specifications of 210T Pongee

Let’s get into the numbers and specs. If you’re sourcing fabric, you don’t want fluff. You want data.

Thread Count and GSM Range

- Thread Count: 210 threads per square inch (hence the name)

- GSM Range: Typically 60–90 GSM

This makes it light enough for portability, but sturdy enough to resist tearing under light stress.

Yarn Composition and Construction

- Yarn Type: Usually 75D or 100D polyester filament

- Weave Type: Plain weave

- Warp/Weft Ratio: Generally 75D x 75D or 75D x 100D, depending on the end-use.

The yarn is continuous filament, which adds strength and smoothness, making it great for printing.

Common Coatings and Functional Finishes

Most manufacturers add:

- PU Coating: Adds water resistance

- WR (Water Repellent): For umbrellas or tents

- AC Coating: For silky smooth finish

- PVC or PA Coating: For enhanced weatherproofing

That’s where the magic happens—coatings take this fabric from “meh” to “ready-for-the-outdoors.”

Where is 210T Pongee Fabric Used?

This fabric shows up in more places than you'd expect.

Outdoor Gear and Equipment

Think of your pop-up tent, windbreaker jacket, or car cover—there’s a high chance they use 210T Pongee. With a PU or PVC coating, it resists rain and UV rays well.

Apparel Industry Applications

Fashion? Absolutely.

- Jacket linings

- Raincoats

- Windcheaters

Why? Because it’s ultra-light, doesn’t add bulk, and still provides that subtle structure.

Promotional and Custom Products

Ever got one of those free branded umbrellas or drawstring bags? That’s often 210T Pongee. It’s cheap to print on, lightweight to ship, and gives decent durability for short-term use.

Advantages of 210T Pongee Fabric

No marketing fluff—just solid benefits.

Durability and Weather Resistance

Even at a lower GSM, the tight weave and coating make it resistant to water, wind, and UV exposure. Not bulletproof, but pretty darn tough for the weight.

Lightweight and Easy Storage

A square meter weighs less than 90g. That’s perfect for products like:

- Packable jackets

- Compact rain covers

- Foldable bags

You won’t need a gym session just to carry your umbrella.

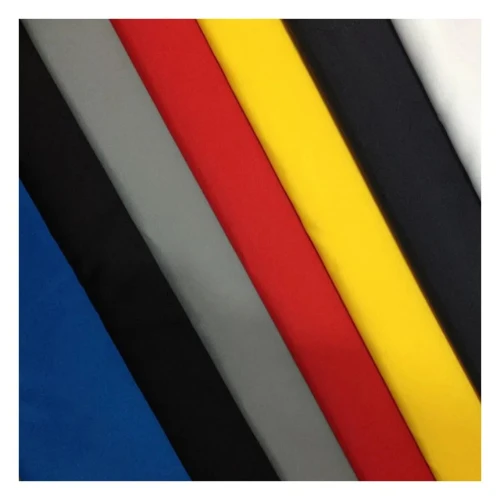

Printing and Color Retention

With high dye affinity, 210T Pongee prints crisp graphics and logos. That’s why it’s everywhere in corporate giveaways and event merch. The coating also helps retain color even after some exposure to the sun or rain.

Limitations to Consider

Nothing’s perfect. And yes, 210T Pongee has its limits.

Not Ideal for Heavy-Duty Loads

Trying to carry bricks or a laptop in a 210T pongee bag? Not smart. It’s built for light usage, not heavy hauling.

Moderate Breathability

This fabric doesn’t breathe like cotton or mesh. So, it’s fine for linings or rain protection, but not ideal as a standalone fabric for warm-weather wear.

Final Thoughts: Is 210T Pongee Right for Your Project?

If you want a fabric that’s affordable, lightweight, printable, and weather-resistant, 210T Pongee hits the mark. It’s not for industrial strength needs, but for everyday covers, linings, and promotional items? It’s almost unbeatable.

When performance meets affordability, 210T Pongee stands tall.

FAQs on 210T Pongee Fabric

1. Is 210T Pongee waterproof?

Not by itself. But with PU or PVC coating, it becomes water-resistant enough for umbrellas or tents.

2. How strong is 210T Pongee fabric?

It’s strong for its weight. With 75D polyester yarn, it handles daily wear and tear but isn’t meant for heavy loads.

3. Can I print on 210T Pongee?

Absolutely. It holds colors well, especially with dye-sublimation or screen printing methods.

4. What is the difference between 190T and 210T Pongee?

The 210T has a higher thread count, making it smoother, slightly heavier, and more durable than 190T Pongee Fabric.

5. What is the GSM of 210T Pongee fabric?

Typically, it ranges between 60 and 90 GSM, depending on coating and construction.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.