Concerning high-quality, durable fabrics, 300T Taffeta stands out as a reliable option. It is known for its fine texture, durability, and versatility. 300T taffeta fabric is commonly used in both fashion and outdoor gear. This article will explore everything about 300T taffeta, from its key properties to its various applications.

Table Of Contents

What is 300T Taffeta Fabric?

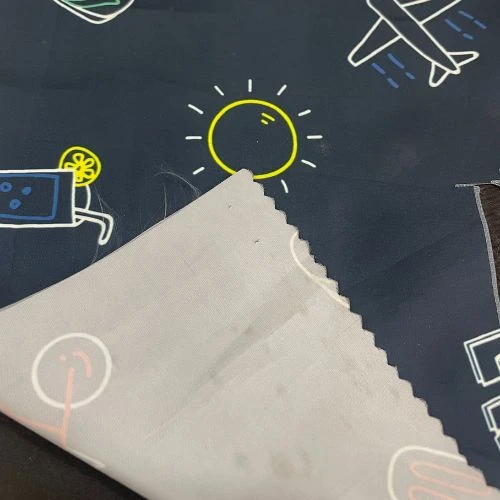

300T Taffeta Fabric refers to a specific type of taffeta with a thread count of 300 threads per inch (TPI). The higher the thread count, the smoother and stronger the fabric. This particular variant of taffeta is made using a plain weave, giving it a distinct texture that’s soft yet firm.

The "T" in 300T stands for the thread count per square inch. And 300 stands for 300 threads. This fabric offers a fine, dense weave, which results in increased strength, smoothness, and resistance to wear and tear. Typically made from synthetic fibers like nylon or polyester, 300T taffeta is widely used in many industries.

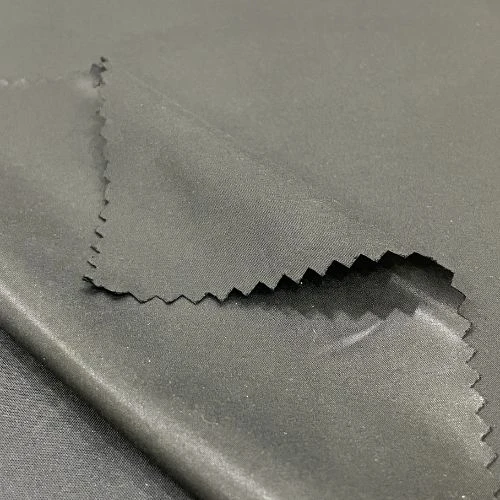

Figure: 100% Polyester 300T Taffeta Fabric

|

Attribute |

Description |

|

Fabric Name |

300T Taffeta Fabric |

|

Fabric Also Known As |

High-Thread-Count Taffeta |

|

GSM Range |

60-80 GSM |

|

Composition Range |

100% Nylon, 100% Polyester |

|

Construction Range |

Plain Weave |

|

Manufacturing Process |

Weaving, Dyeing, Coating (if required) |

|

Possible Thread Count Variations |

300 threads per inch (TPI) |

|

Full Width |

57/58 inches, 59/60 inches |

|

Cuttable Width |

Typically 56-58 inches |

|

Fabric Breathability |

Low breathability (due to dense weave) |

|

Additional Coating Variation |

PU, PVC, Cire, Flame-Retardant |

|

Moisture-Wicking Abilities |

Moderate (depends on coating) |

|

Heat Retention Abilities |

Moderate (varies with down-proof and additional coatings) |

|

Stretchability |

No inherent stretch (non-stretch fabric) |

|

Prone to Pilling/Bubbling |

Low (durable and smooth finish) |

|

Country Where Fabric Was First Produced |

It likely originated from Europe or Asia |

|

Biggest Exporting Country Today |

China |

|

Recommended Washing Temperatures |

Cold to warm water, around 30-40°C (86-104°F) |

|

Common Applications |

Tents, Jackets, Umbrellas, Sleeping Bags, Backpacks, Event Decorations |

Types of 300T Taffeta Fabric

When it comes to 300T taffeta fabric, there are several types, each designed to meet specific needs and applications. The variations in coatings, treatments, printing and fiber compositions give this fabric different properties, making it adaptable for diverse industries.

1. 300T PU-Coated Taffeta Fabric

This type of 300T taffeta is treated with a polyurethane (PU) coating, which enhances its water resistance. The coating forms a protective layer on the surface of the fabric, preventing water from penetrating the material. It also increases the fabric’s durability, making it more resistant to wear and tear.

Applications:

PU-coated 300T taffeta is widely used in outdoor gear, such as tents, rain jackets, and backpacks. The water-resistant feature makes it suitable for products exposed to rain or moisture.

2. 300T PVC-Coated Taffeta Fabric

This variant features a polyvinyl chloride (PVC) coating that provides an even higher level of water resistance and durability than PU coatings. PVC coatings are thicker and more robust, making the fabric nearly waterproof.

Applications:

PVC-coated 300T taffeta is commonly used in heavy-duty outdoor equipment, such as tarps, ground sheets, and industrial covers. The extra layer of protection ensures that the fabric can withstand prolonged exposure to harsh environments.

3. Flame-Retardant 300T Taffeta Fabric

Flame-retardant 300T taffeta has been treated with chemicals to reduce flammability. This treatment allows the fabric to resist ignition or slow down the spread of flames. This type of fabric is essential for safety-conscious applications.

Applications:

This fabric is frequently used in fire-resistant clothing, tents for events, and safety gear. It is particularly important in industries where fire hazards are a concern, such as industrial workplaces or outdoor settings.

4. 300T Ripstop Taffeta Fabric

Ripstop taffeta is a special type of taffeta that features a reinforced weave, with thicker threads integrated into the fabric in a grid pattern. This structure prevents tears from spreading, offering enhanced durability without significantly increasing weight.

Applications:

Ripstop 300T taffeta is ideal for parachutes, kites, outdoor tents, and sports gear, where strength and tear resistance are critical. The fabric’s lightweight nature makes it popular for camping gear as well.

5. 300T Downproof Taffeta Fabric

Downproof taffeta is tightly woven to prevent the escape of feathers and down filling. The high thread count of 300T ensures that the fabric is dense enough to hold even the smallest down feathers securely inside the material.

Applications:

This type of 300T taffeta is mainly used in down jackets, sleeping bags, and pillows. The fabric helps maintain insulation by keeping the down inside, ensuring warmth and comfort.

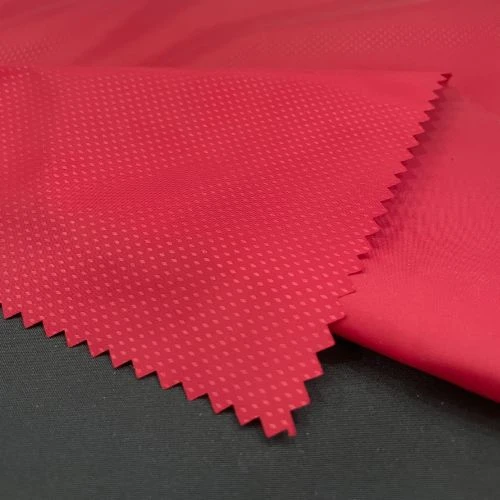

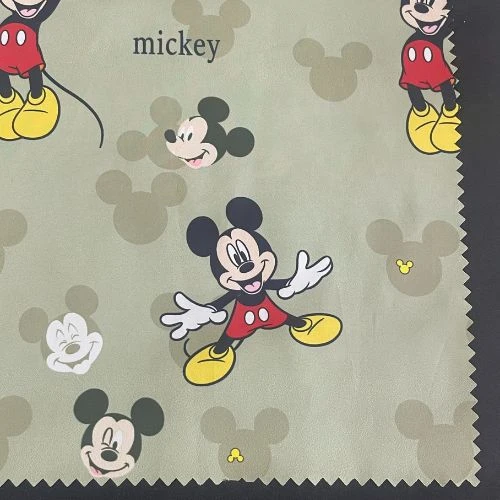

6. 300T Printed Taffeta Fabric

Printed 300T taffeta is customized with various patterns or designs through digital or screen printing techniques. e.g: 300T embossed printed taffeta fabric. The base fabric is the same smooth, but with added visual texture is different.

Figure: Emboss Print 300T Taffeta Fabric

Applications: Printed 300T taffeta is often used in event decorations, fashion garments, and bags. The fabric’s smooth surface allows for high-quality printing that adds a touch of style and personalization.

7. Cire-Finished 300T Taffeta Fabric

Cire (or "waxed") taffeta fabric has a glossy, shiny finish that is achieved through a heated calendaring process. This gives the fabric a polished, reflective surface, enhancing its appearance and making it more resistant to water.

Applications: Cire-finished 300T taffeta is popular in fashion, particularly for high-gloss jackets, bags, and accessories. The glossy finish also makes it a great choice for decorative purposes, such as drapes and backdrops.

Key Characteristics of 300T Taffeta Fabric

What makes 300T taffeta so popular? Let’s look at its defining features:

- High Thread Count: With 300 threads per inch, this fabric is stronger and more durable than lower-thread-count versions, such as 190T or 210T taffeta.

- Smooth Surface: The high thread count ensures a smooth, sleek finish, making the fabric feel more premium and polished.

- Water Resistance: Many 300T taffeta fabrics are treated with coatings, such as PU (polyurethane) or PVC (polyvinyl chloride), to enhance water resistance, making them ideal for outdoor gear.

- Lightweight Yet Strong: Despite its strength, the fabric remains lightweight, with an average weight of 60-80 grams per square meter (GSM), which makes it perfect for applications where both strength and portability are needed.

- Low Air Permeability: Thanks to its tight weave, 300T taffeta offers excellent wind resistance, making it a top choice for jackets, windbreakers, and other outerwear.

Applications of 300T Taffeta Fabric

300T taffeta’s unique combination of strength, smoothness, and lightweight properties makes it suitable for a wide range of applications. Let’s look at the most common uses:

1. Outdoor Gear

Because of its durability and water resistance, 300T taffeta is commonly used in tents, sleeping bags, and backpacks. Its lightweight nature makes it easy to carry during outdoor activities, while its strength ensures it can withstand harsh conditions like rain and wind.

2. Fashion Industry

In the fashion world, 300T taffeta is favored for jackets, raincoats, and windbreakers. Its smooth surface gives clothing a sleek appearance, while its strength ensures the fabric won’t easily tear. It's also used in making lining for bags and garments due to its soft and breathable nature.

3. Umbrellas

300T taffeta is an excellent material for umbrellas. Its tight weave and water-resistant coatings help keep the rain out while offering enough flexibility to open and close the umbrella easily. Plus, the fabric’s durability makes umbrellas last longer under regular use.

4. Event Decorations

Because of its shiny appearance and smooth texture, 300T taffeta is often used for decorative purposes in events, such as backdrops, tablecloths, and drapes. Its luxurious look adds a touch of elegance to events like weddings and banquets.

Advantages of Using 300T Taffeta Fabric

Now that we know where 300T taffeta is used, let’s explore why it’s preferred over other fabrics.

Strength and Durability

300T taffeta's high thread count makes it extremely durable. The fabric holds up well in rough conditions, making it perfect for outdoor activities. It resists tearing and maintains its structure even after extended use.

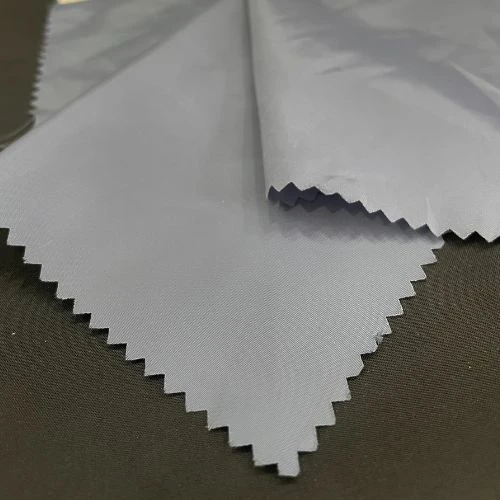

Water Resistance

Figure: 300T Taffeta Printing with Water Resistant Finishing

Many versions of 300T taffeta are coated to be water-resistant or waterproof. The fabric repels water and dries quickly, making it ideal for rainy weather and wet environments. Its water resistance is further enhanced by polyurethane coatings, which can protect up to 99% of water exposure.

Lightweight and Portable

Despite its high strength, 300T taffeta remains lightweight. This combination of durability and low weight is a major advantage for products like tents and sleeping bags, where portability is crucial. At 60-80 GSM, it offers excellent strength-to-weight ratio.

Care Instructions for 300T Taffeta Fabric

Taking care of 300T taffeta is simple but essential to maintain its durability and performance. Here’s a quick guide on how to properly care for this fabric:

- Washing: Machine wash in cold water on a gentle cycle. Avoid using harsh detergents, which may wear down coatings like PU or PVC.

- Drying: Air dry whenever possible. If using a dryer, set it to low heat to prevent any damage to the fabric.

- Ironing: If needed, iron on a low heat setting. High heat can damage the fabric’s synthetic fibers or melt the water-resistant coating.

- Storage: Store the fabric in a cool, dry place away from direct sunlight. UV exposure may weaken the fabric over time.

Conclusion

300T Taffeta Fabric is a versatile material known for its strength, smooth texture, and lightweight properties. With applications ranging from outdoor gear to fashion, this fabric offers a unique blend of performance and aesthetics. Whether you're crafting a raincoat or designing a tent, 300T taffeta is an excellent choice for projects that demand durability, water resistance, and style.

Frequently Asked Questions (FAQs)

1. Is 300T taffeta fabric waterproof?

Many 300T taffeta fabrics come with water-resistant coatings, but not all versions are fully waterproof. Look for fabrics with PU or PVC coatings for added protection against water.

2. How does 300T taffeta compare to 210T taffeta?

300T taffeta has a higher thread count than 210T, making it smoother and more durable. However, 210T taffeta is lighter and may be preferred for applications where weight is a concern.

3. Can 300T taffeta be used for everyday clothing?

Yes, 300T taffeta is commonly used in jackets, raincoats, and windbreakers. Its smooth texture and water-resistant properties make it suitable for outerwear.

4. Does 300T taffeta stretch?

No, 300T taffeta is not a stretchable fabric. It is a non-stretch material that retains its shape well under stress.

5. Can you dye 300T taffeta?

Yes, 300T taffeta can be dyed, but it requires special dyes designed for synthetic fabrics like nylon or polyester. The dyeing process may vary depending on the fiber composition and coatings used.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.