Ever held a windbreaker that felt ultra-smooth but didn’t know what made it that way? Chances are, it was made from 350T Taffeta Fabric—a quiet powerhouse in the textile world. Let’s unravel this fabric layer by layer.

|

Category |

Details |

|

Also Known As |

High-density Taffeta, 350 Thread Count Taffeta |

|

Manufacturing Process |

Plain weave on water-jet or air-jet loom; dyed or greige → coated/finished |

|

Appearance |

Smooth, slightly glossy or matte finish, crisp handle |

|

GSM Range |

60 – 90 GSM |

|

Composition Range |

100% Polyester / 100% Nylon |

|

Construction Range |

50D × 50D / 100D × 100D – 350T Thread Count |

|

Functionality |

TPU, PU, PVC, AC (Anti-static), W/R (Water Repellent), PV (Polyurethane Vapor) |

|

Possible Yarn Count |

20D, 30D, 50D, 70D, 100D (both FDY & DTY) |

|

Full Width Options |

57/58", 59/60", 71/73" |

|

Fabric Breathability |

Low to Medium (depends on coating) |

|

Stretchability |

Non-stretch (unless elastomeric blended or mechanical stretch added) |

|

Prone to Pilling/Bubbling |

No (if finished properly); PU-coated fabrics may bubble over time with heat/humidity |

|

Country of First Production |

France, approx. 1950s (commercial polyester taffeta) |

|

Biggest Exporter Country |

China (~72% global export share in 2023; ~880,000 tons) |

|

Recommended Washing Temp. |

30–40°C (cold to lukewarm); hand/machine gentle cycle |

|

Finishing Uses to Increase Functionality |

UV coating, Antimicrobial, Flame retardant (FR), Antistatic, Down-proof coating |

|

Environmental Concerns |

Microfiber shedding, Petrochemical-based; use RPET or bio-based versions to reduce impact |

|

Color Fastness |

4–5 (Good to Excellent, with correct dyeing & fixatives) |

|

Tear Strength |

12–18 N (ISO 13937-1) depending on denier and coating |

|

Air Permeability |

<5 mm/s (ASTM D737, coated) → Low airflow for wind-resistance |

|

Water Resistance (PU coated) |

1000–3000 mm Hâ‚‚O (Hydrostatic Head Rating) |

|

UV Resistance (if treated) |

Up to 95% UV blocking |

|

Shrinkage Rate |

<3% (if heat-set and pre-shrunk) |

|

Applications |

Tents, Raincoats, Jacket linings, Sleeping bags, Umbrellas, Banners, Medical PPE covers, Duffel bags, Parachutes |

|

Lifecycle Expectancy |

2–5 years (depends on exposure & coating quality) |

|

Printing Compatibility |

Suitable for sublimation (polyester), screen, and digital printing |

|

Certifications (when eco-friendly) |

OEKO-TEX®, GRS (for RPET), Bluesign®, REACH compliant |

|

MOQ in Export Markets |

Usually 1000–3000 meters per color/design |

|

Avg. Price per Meter (Bulk) |

$0.70 – $1.20 USD (depends on coating, yarn type, and origin) |

Table Of Contents

What Does “350T” Really Mean in Fabrics?

Understanding Fabric Thread Count

"350T" stands for 350 threads per square inch. Higher thread counts mean a denser weave. For comparison:

- 210T = more breathable, lighter, but less durable

- 300T = good middle ground

- 350T = tighter, smoother, more water-resistant

In simple terms, the higher the T, the silkier the touch and the stronger the shield.

350T vs 300T vs 210T – What’s the Difference?

|

Feature |

210T |

300T |

350T |

|

Feel |

Light, papery |

Medium smooth |

Smooth, slick |

|

Weight |

Low GSM |

Mid GSM |

Higher GSM |

|

Water Resistance |

Moderate |

Good |

Very Good |

|

Price Point |

Low |

Mid |

Slightly higher |

Manufacturing Process of 350T Taffeta

Weaving Method

350T Taffeta uses a plain weave structure. The warp and weft crisscross tightly, producing a crisp, firm fabric. This uniform weave keeps it lightweight but strong, ideal for both apparel and industrial use.

Finishing Options (PU, WR, AC, etc.)

Finishes matter—a lot. Here’s what 350T Taffeta can come with:

- PU coating: For waterproofing

- WR (Water Repellent): Light rain resistance

- AC (Anti-static Coating): Keeps shocks away

- PVC or TPU: Extra strength for tarps and covers

Key Characteristics of 350T Taffeta

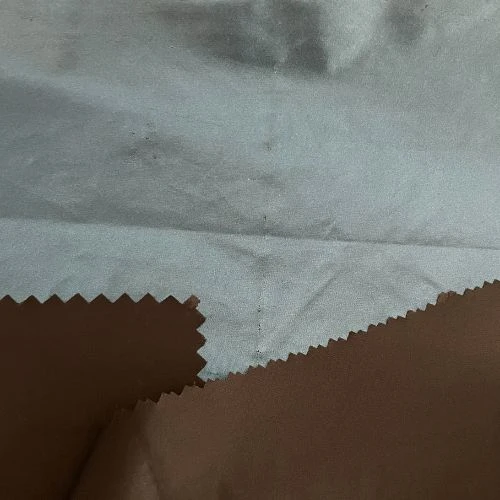

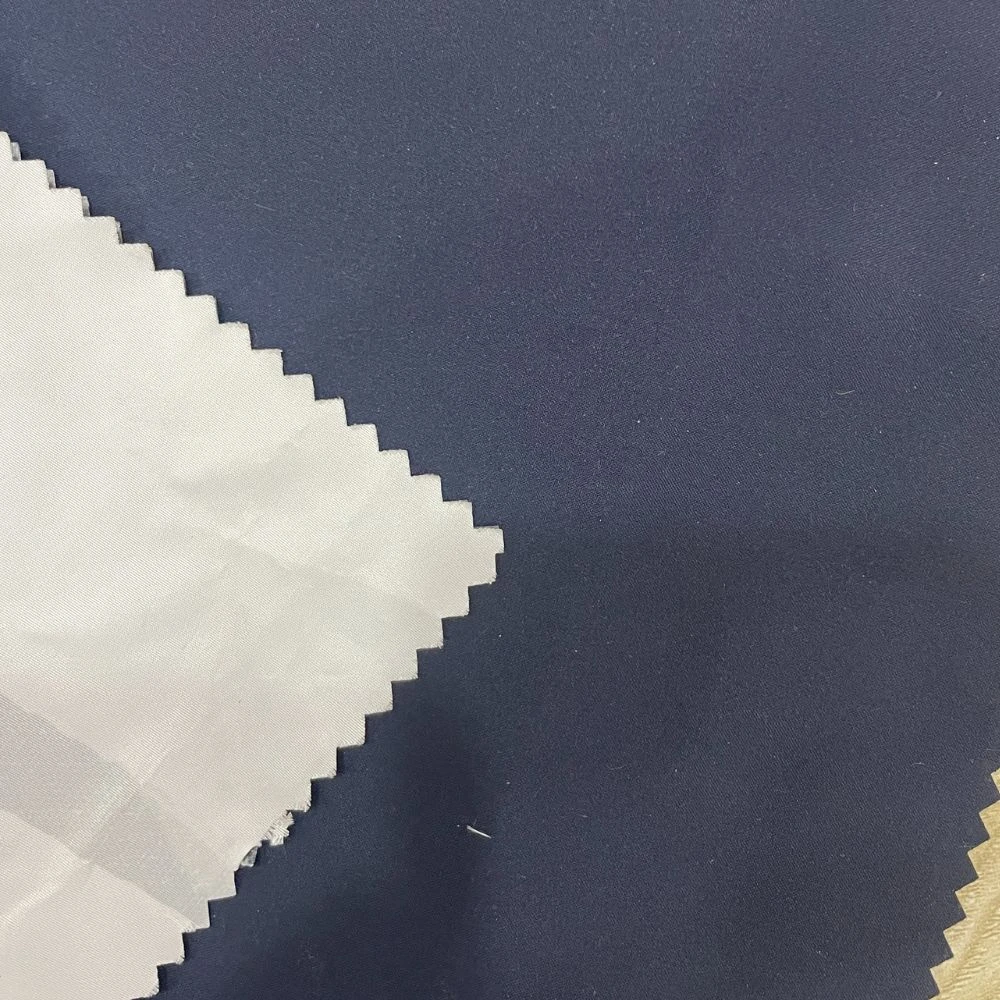

Appearance and Texture

Think: matte or semi-glossy surface that feels slightly slippery. You can dye it into deep, rich shades that don’t fade easily.

GSM Range and Fabric Weight

Typically, 350T Taffeta lands around 60–90 GSM depending on the yarn and finish. Not heavy—but not featherlight either.

Durability and Usage

It doesn’t tear easily. Despite being lightweight, the high thread count gives it high tensile strength. That’s why it often ends up in camping gear or umbrellas.

Technical Specifications of 350T Taffeta Fabric

Possible Yarn Count

Usually spun from 20D–50D polyester or nylon fabric. Lower denier means smoother texture and lighter weight.

Construction Range

Examples include:

- 100D x 100D, 350T

- 50D x 50D, 350T

You’ll typically find plain weave in these specs.

Standard Width and Composition

- Width: 57/58", 59/60", or sometimes up to 71/73"

- Composition: 100% polyester or 100% nylon

Polyester versions resist wrinkles better, while nylon gives better softness.

Breathability and Stretchability

- Breathability: Low to medium

- Stretchability: Not stretchy unless blended with spandex

Great for windbreaking, not for yoga pants.

Common Uses of 350T Taffeta

Outdoor and Waterproof Applications

- Tents

- Backpacks

- Sleeping bag liners

- Umbrellas

- Raincoats

Thanks to its finish compatibility, this fabric stands tall against water and wind.

Fashion and Functional Clothing

350T isn’t just brawn—it’s beauty too:

- Lining material in jackets

- Windbreakers

- Formal dress linings

- Costume fabrics

Final Thoughts

350T Taffeta is like that quiet student in class who ends up becoming CEO. It’s subtle, smooth, and seriously strong. Whether you’re designing rainwear or backpacking tents, this fabric ticks the right boxes.

FAQs

Q1: Is 350T Taffeta waterproof?

Not by itself. It becomes waterproof with PU or TPU coating.

Q2: Is 350T better than 300T Taffeta?

It depends on your use. For stronger, smoother output, yes—350T wins.

Q3: Can 350T Taffeta be used for clothing?

Absolutely. It's perfect for jacket linings and outerwear.

Q4: What’s the GSM of 350T Taffeta?

Typically ranges from 60 to 90 GSM, depending on yarn and coating.

Q5: Is 350T made of polyester or nylon?

Both versions exist. Polyester is more common; nylon is softer and pricier.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.