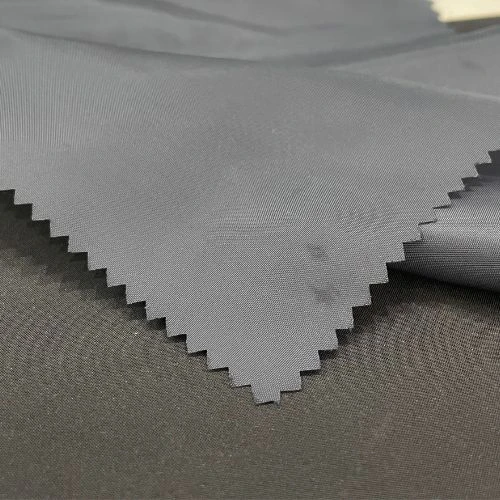

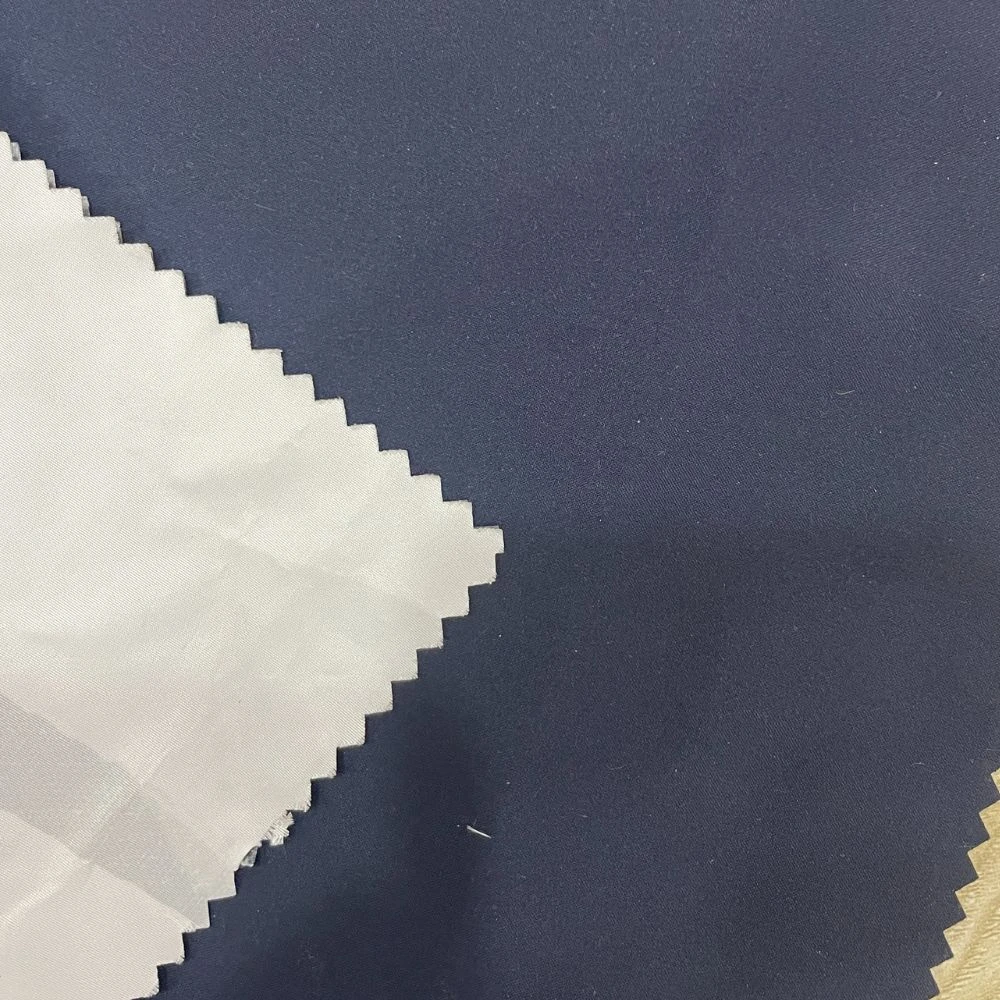

230T Taffeta fabric is a lightweight, tightly woven textile made from polyester or nylon. It’s known for its crisp texture, shiny surface, and excellent wind and water resistance. But don't let the softness fool you—this fabric is tough. It’s used where durability meets performance.

|

Parameter |

Details |

|

Also Known As |

High-density Taffeta, 230T Lining Fabric, 230T Polyester Taffeta |

|

“230T” Definition |

230 threads per square inch (Thread Count) |

|

Manufacturing Process |

Plain weave → Dyeing → Coating (PU/PA/AC) → Finishing |

|

Appearance |

Smooth, glossy surface; slightly stiff; lightweight |

|

GSM Range |

55–75 GSM |

|

Composition Range |

100% Polyester (PES) or 100% Nylon (PA6/PA66) |

|

Construction (Weaving) |

Plain weave |

|

Functionality Coatings |

PU (Polyurethane), PA (Polyamide), PVC, AC (Acrylic), WR (Water-Repellent), TPU (Thermoplastic Polyurethane), Silver Coating |

|

Possible Yarn Count |

70D/68F, 75D/72F, 210D/72F |

|

Full Width Options |

57/58”, 59/60”, 71/73” |

|

Fabric Breathability |

Moderate (depends on coating, PU is more breathable than PVC) |

|

Stretchability |

No (unless spandex is added) |

|

Prone to Pilling/Bubbling |

Low if coated; medium if uncoated |

|

Country of First Production |

France (approx. mid-19th century for taffeta; 230T spec modernized ~1980s) |

|

Biggest Exporter (by volume) |

China – Over 400 million meters/year (Global Textile Trade, 2023) |

|

Recommended Washing Temperature |

Cold to warm wash (30–40°C), do not bleach or tumble dry |

|

Finishing Treatments |

Anti-UV, Anti-static, Flame retardant, Down-proof, Silver/Aluminum coating |

|

Tensile Strength |

Warp: ~180–220 N / Weft: ~130–160 N (depending on coating and fiber) |

|

Tear Strength |

7–12 N (coated), higher with PU or TPU finishes |

|

Shrinkage |

Minimal (≤ 2%) |

|

Water Column (Waterproof Rating) |

600–3000 mm (varies by coating type) |

|

Color Fastness (to Light) |

3–4 (ISO 105 standard) |

|

Color Fastness (to Washing) |

4–5 (ISO 105 C06 standard) |

|

Eco-Variants Available? |

Yes (Recycled Polyester, GRS certified versions) |

|

Applications |

Outerwear lining, Raincoats, Windbreakers, Tent linings, Umbrellas, Sleeping bags, Parachutes, Drawstring bags, Kite fabric, Car covers |

|

Printability |

Excellent with digital and sublimation printing |

|

UV Resistance |

Moderate to High (better in PA-coated or UV-finished variants) |

|

Drying Speed |

Fast drying due to synthetic fiber base |

Table Of Contents

Understanding the “230T” in 230T Taffeta

Thread Count Demystified

So what does the “230T” mean? “T” stands for threads per inch. A 230T fabric has 230 threads woven into every square inch. That’s higher than your average T-shirt and just under what’s used in some premium down-proof linings.

More threads mean denser fabric, better barrier properties, and higher tear strength, without making it too heavy.

Why 230T Matters in Fabric Strength

Compared to 190T taffeta fabric (which has 190 threads per inch), 230T offers better abrasion resistance and slightly higher moisture protection. It’s the sweet spot between flexibility and performance.

Composition and Construction

What Materials Are Used?

230T taffeta is usually made from polyester (PES) or nylon (PA6 or PA66). Polyester is more affordable and UV resistant, while nylon offers more softness and stretch.

Common fiber deniers:

- 70D or 75D polyester

- 210D nylon

These values show the fiber’s thickness. For 230T, 70D–75D is the norm.

Weaving Technique Behind the Gloss

Taffeta is a plain-woven fabric. That means the yarns crisscross over and under each other—nothing fancy, but very effective. The tight weaving pattern, combined with finishing treatments, gives taffeta its signature silky sheen.

GSM Range and Physical Properties

GSM stands for grams per square meter, or how heavy the fabric is.

- GSM Range: 55–75 GSM

- Width: Usually 57/58"

- Stretchability: None (unless blended)

- Pilling: Low if coated

- Shrinkage: Minimal

Key Characteristics of 230T Taffeta

Waterproof, Windproof, and Wrinkle-Resistant

Many 230T fabrics get a PU (polyurethane) or PA (polyamide) coating to make them water-repellent or fully waterproof. Great for windbreakers and tent flysheets.

It also doesn’t wrinkle easily. If you hate ironing (who doesn’t?), taffeta’s on your side.

Fabric Breathability and Coatings (PU, PA, PVC)

- PU Coated: Waterproof and breathable

- PA Coated: Glossy finish and UV resistant

- PVC Coated: Best for water resistance, but less breathable

Each coating adds different functionality. Want a quick-drying jacket? Go with PU. Need UV protection? Choose PA.

Color Fastness and Dyeing Behavior

230T polyester taffeta holds dye well and resists fading, even under sun exposure. That’s why it’s a popular pick for vibrant outerwear and outdoor gear.

Where Is 230T Taffeta Fabric Used?

In Outerwear and Rain Jackets

Lightweight yet protective, it’s ideal for windcheaters and raincoats. The coating ensures no water leaks through during sudden downpours.

In Tent Linings, Sleeping Bags, and Backpacks

Many tents use 230T for inner linings, offering moisture control while keeping things light. It’s also seen in drawstring bags and ultralight backpacks where every gram counts.

Industrial and Home Applications

From car covers to parachutes and umbrella canopies, this fabric is more versatile than it looks.

Pros and Cons of 230T Taffeta

Advantages

- Lightweight (approx. 60 GSM)

- Water- and wind-resistant

- Affordable

- Strong for its weight

- Easy to dye and print on

- Doesn’t wrinkle much

Limitations to Watch Out For

- Not naturally breathable

- Can feel stiff without softeners

- No stretch (unless blended with spandex)

- Might be noisy (yes, it crinkles!)

Conclusion

230T Taffeta fabric is a quiet performer—lightweight, shiny, and tougher than it looks. It handles rain, wind, and wear like a champ. Whether you’re hiking a mountain or biking in the city, chances are this fabric is somewhere on you, working in silence.

For textile makers, it’s a reliable base. For everyday users, it’s comfort wrapped in durability. Don’t overlook it next time you check a product tag—230T might just be the unsung hero in your gear.

FAQs About 230T Taffeta Fabric

1. Is 230T Taffeta good for rainwear?

Yes! Especially when PU or PA coated, it’s highly water-repellent and wind-resistant.

2. How does it compare with 190T or 300T?

230T is denser than 190T (better durability) but lighter than 300T (more breathable).

3. Can I use it for outdoor tents?

Definitely, it’s used in tent linings and flysheets for moisture control and wind protection.

4. Does it stretch?

No, unless blended with spandex or similar elastic fibers.

5. How long does it last?

With proper coating and care, 230T taffeta can last 3–5 years or more in regular use.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.