Ever held a sleek windbreaker or set up a rustle-free tent and thought, “What fabric is this?” Chances are, it’s 300T taffeta. This fabric doesn't just sound fancy. It blends technical performance with a smooth touch. Let's peel back the layers and make it simple.

|

Property |

Details |

|

Also Known As |

High-density taffeta, Fine polyester taffeta, 300-thread count taffeta |

|

Manufacturing Process |

Woven using plain weave on water-jet or air-jet looms |

|

Appearance |

Smooth, crisp, slightly shiny or matte (depending on finishing) |

|

GSM Range |

55 – 75 GSM |

|

Composition Range |

100% Polyester, 100% Nylon, or blends (usually 90/10 or 80/20) |

|

Construction Range |

300T (typically 150D x 150D, or 75D x 75D) |

|

Functionality (Coatings/Finishes) |

TPU, PU, AC, W/R (Water Repellent), PV (Polyvinyl), PVC, Silver-coated, Anti-UV |

|

Possible Yarn Count |

75D/72F, 50D/72F, 150D/96F, depending on finish and application |

|

Full Width |

Commonly 57/58", 59/60", 71/73" |

|

Fabric Breathability |

Low to Moderate (Improved with microporous or perforated coatings) |

|

Stretchability |

Non-stretch (unless blended with spandex/elastane) |

|

Prone to Pilling/Bubbling |

Very low due to smooth surface and tightly woven structure |

|

Country of Origin (Year) |

France, ~18th Century (used historically for dresses and linings) |

|

Biggest Exporter Country |

China (Exports over 50% of global polyester taffeta fabric annually) |

|

Recommended Washing Temp. |

30°C to 40°C (cold to warm), no bleach, gentle cycle |

|

Finishing Uses for Functionality |

Calendering (for shine), Coating (for water/UV resistance), Heat setting (for shape retention) |

|

Shrink Resistance |

High (due to synthetic nature and heat setting) |

|

UV Resistance |

Moderate (Polyester is better than Nylon for UV) |

|

Color Fastness |

High, especially with disperse dyeing in polyester variants |

|

Abrasion Resistance |

Moderate to high (enhanced with PU or PA coatings) |

|

Mildew Resistance |

High (synthetic fiber + water-repellent coatings) |

|

Tear Strength |

High (especially with 300T weave and reinforced yarns) |

|

Applications |

Outdoor tents, sleeping bags, windbreakers, jackets, linings, flags, hospital garments, gear bags |

Table Of Contents

What Does 300T Mean in Fabric?

Thread Count Demystified

First things first—300T stands for 300 threads per square inch. In the textile world, that’s a pretty tight weave. For reference, 190T fabric only squeezes in 190 threads in the same space. More threads mean a denser, stronger fabric.

How It Affects Fabric Performance

Here’s the impact:

- Better water resistance (less space between threads)

- Higher tensile strength—harder to tear

- Smoother feel—like a gentle rub of silk

Manufacturers love it for gear that must be both tough and light.

Key Features of 300T Taffeta Fabric

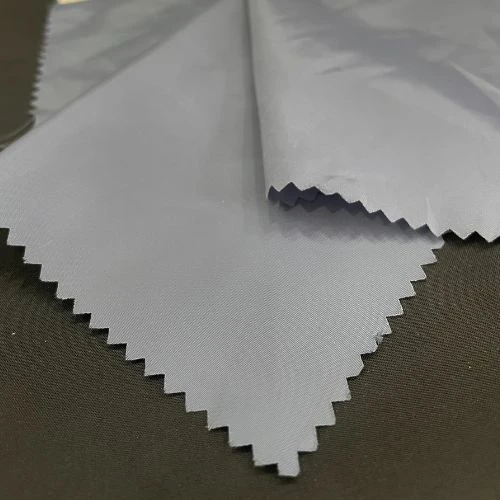

Texture and Finish

300T taffeta feels soft but not fuzzy. It’s crisp, often with a subtle shine. Depending on the fiber—polyester or Nylon Taffeta fabric, it can be matte or glossy. You’ll notice it’s slippery to the touch, ideal for linings and shells.

Strength and Durability

Thanks to the high thread count, this fabric stands strong. Tensile strength tests often show polyester 300T taffeta resisting over 250 N (newtons) before tearing. That’s serious resilience in something so thin.

Common Coatings (PU, PA)

A big reason 300T taffeta excels outdoors? Coatings.

- PU (Polyurethane): Adds waterproofing. Think tents, ponchos, or covers.

- PA (Polyamide): Boosts durability and abrasion resistance.

Some versions even use silver coatings for thermal insulation. Fancy, right?

Popular Uses of 300T Taffeta Fabric

Outdoor Gear and Equipment

You’ll see this fabric in:

- Sleeping bags (both shells and linings)

- Lightweight tents

- Windbreakers

- Raincoats

Why? It’s water-resistant, lightweight, and packs down small.

Fashion and Lining Materials

In clothing, 300T taffeta works well as a lining. It helps jackets glide over your sweater rather than bunch up. Designers also use it for skirts and dresses where they want a bit of structure.

Medical and Protective Applications

Thanks to its coating options, 300T taffeta also shows up in:

- Hospital gowns

- Surgical covers

- Protective liners

The fabric forms a barrier, which makes it great for sterility and cleanliness.

How 300T Taffeta Compares to Other Fabrics

190T vs 300T Taffeta

Here’s a quick face-off:

|

Feature |

190T Taffeta |

300T Taffeta |

|

Thread Count |

190 |

300 |

|

Feel |

Slightly rougher |

Smoother |

|

Water Resistance |

Basic |

Higher |

|

Durability |

Moderate |

Strong |

Verdict: 300T wins for performance, but 190T is cheaper.

Nylon vs Polyester Taffeta

- Nylon: More flexible, slightly stronger, absorbs more water.

- Polyester: Resists UV better, dries faster, more common in 300T fabric.

Polyester 300T taffeta is the go-to choice for outdoor gear. Nylon versions exist, but they tend to cost more.

Caring for 300T Taffeta Fabric

Washing Tips

Use cold water. Gentle cycle. No bleach. Harsh detergents may strip coatings. Always check the label.

Drying and Ironing Advice

Air drying is best. If you must use a dryer, low heat only. Iron? Avoid it unless absolutely necessary—and only on the lowest heat setting with a cloth barrier.

Conclusion

300T taffeta fabric isn’t just a high-tech term thrown around in catalogs. It delivers performance where it counts—durability, smoothness, water resistance. Whether it’s keeping you dry in a sudden downpour or giving your jacket a silky lining, it works behind the scenes without fuss.

Want fabric that performs but doesn’t weigh you down? You’re looking at it.

FAQs

1. Is 300T taffeta waterproof?

Not by itself, but add a PU or PA coating, and it can resist light to moderate rain.

2. Can I sew 300T taffeta at home?

Yes, but use a fine needle and polyester thread. A walking foot helps with the slippery texture.

3. Is polyester 300T taffeta better than nylon?

For UV resistance and quick drying, yes. But nylon may offer slightly higher strength.

4. Does 300T mean it’s better quality?

Not always. It’s tighter woven than 190T, but coatings and fiber type also affect performance.

5. What’s the weight of 300T taffeta?

Usually between 55–70 GSM (grams per square meter), depending on coatings.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.