210T Taffeta fabric is a tightly woven, smooth, and slightly shiny textile commonly used for linings, windbreakers, tents, and backpacks. The “210T” isn’t a fancy model number—it tells us something important. 210T Taffeta stands for 210 threads per square inch. Wrap has 120, and weft has 90 FDY yarn. Often it has a GSM of 55-58. 150Dx48F is used to produce 210T Taffeta fabric. It indicates its density and durability.

|

Specification |

Details |

|

Also Known As |

Lightweight Taffeta, 210 Thread Count Taffeta, Mid-Density Taffeta |

|

Manufacturing Process |

Woven – Plain Weave (1x1 interlacing) |

|

Appearance |

Smooth, slightly shiny, crisp texture |

|

GSM Range |

55-58 GSM |

|

Composition Range |

100% Polyester or 100% Nylon (some blends may exist) |

|

Construction Range |

210T (Thread Count), ~63D × 63D yarns |

|

Functionality (Finishings) |

PU, PVC, TPU, AC (Acrylic), W/R (Water Repellent), Silver/Aluminum Coating |

|

Yarn Count |

FDY 63D, 65D |

|

Full Width Options |

57/58” |

|

Fabric Breathability |

Low (non-breathable unless perforated) |

|

Stretchability |

No stretch unless blended with spandex |

|

Prone to Pilling/Bubbling |

No (resistant to pilling under normal use) |

|

First Produced |

Japan, approx. 1950s (synthetic taffeta evolution) |

|

Biggest Exporter (2023) |

China – Over 180,000 metric tons/year |

|

Recommended Washing Temperature |

30°C – Gentle cycle with mild detergent |

|

Ironing Temperature |

Max 110°C – Always use a pressing cloth |

|

Drying Method |

Line dry recommended; low tumble if coated |

|

Shrinkage Rate |

<2% when washed properly |

|

Color Fastness (Dry Rubbing) |

4–5 (Good to Excellent) |

|

Tear Strength (Warp/Weft) |

10–15 N |

|

Tensile Strength (Warp/Weft) |

200–350 N |

|

Finishing Uses to Increase Functionality |

Antistatic, UV-Resistant, Flame Retardant, Breathable Lamination |

|

Common Applications |

Tent walls, sleeping bags, windbreakers, rainwear, umbrellas, bag linings, dress linings |

|

Environmental Notes |

Recyclable (PET-based), but coatings may limit biodegradability |

|

Dyeing Method |

Disperse dye (for polyester) or acid dye (for nylon) |

|

Abrasion Resistance |

Moderate (Martindale ~10,000–20,000 cycles depending on finish) |

|

Air Permeability (uncoated) |

5–15 mm/s (very low due to tight weave) |

|

Coating Thickness (if PU/PVC applied) |

0.02–0.05 mm additional layer thickness |

Table Of Contents

Composition and Manufacturing

What Does 210T Stand For?

The “T” in 210T refers to thread count, a unit used to measure fabric density. With 210 threads per square inch. 210T Taffeta lands in the mid-weight category, ideal for both durability and flexibility. It’s more rugged than 190T but lighter than 300T Tafetta fabric or higher.

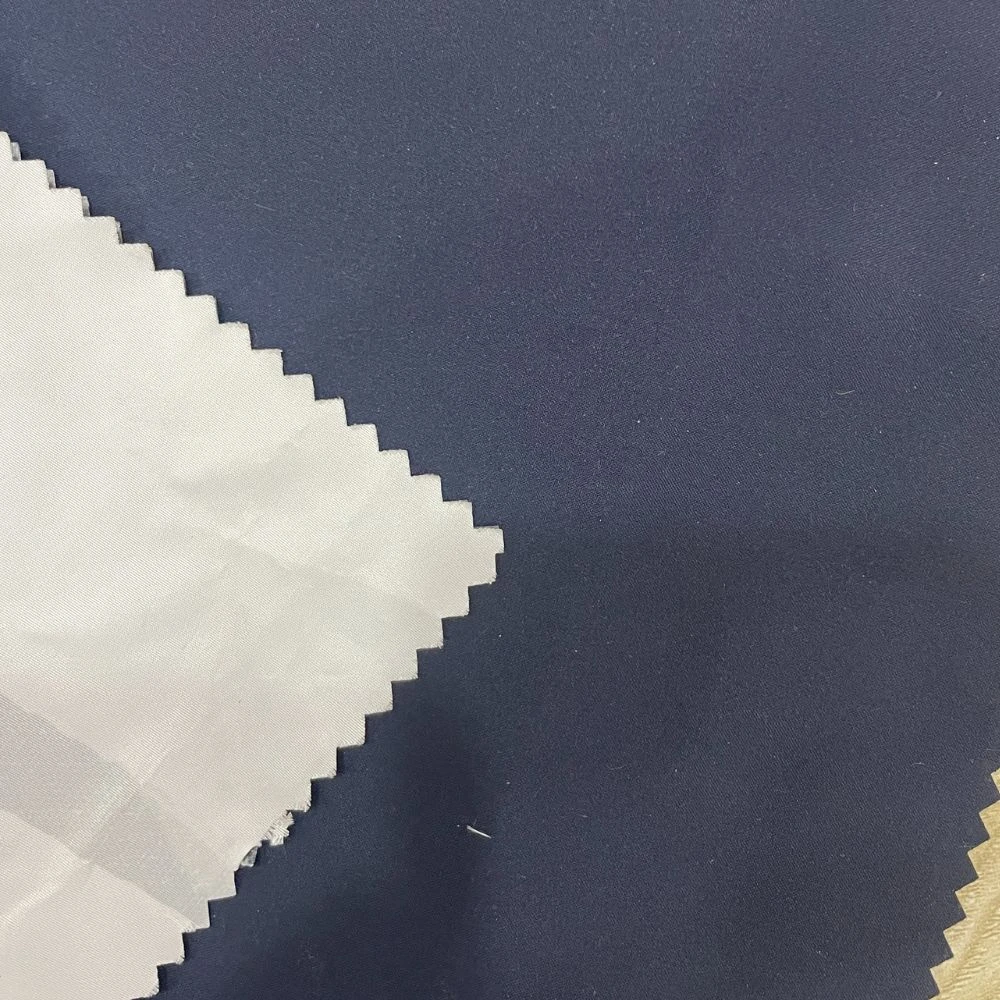

Fiber Types Used in 210T Taffeta

You’ll usually find 210T made from polyester or nylon. Here’s how they compare:

- Polyester: Strong, UV-resistant, cost-effective

- Nylon: Softer, stronger tear resistance, a bit more expensive

Both fibers are synthetic, giving the fabric resistance to mildew, quick drying time, and lower water absorption.

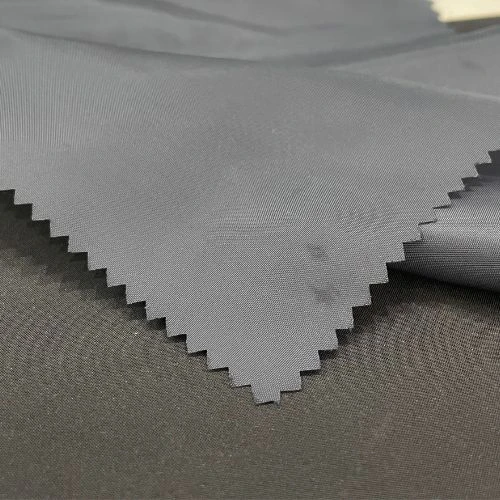

How It’s Woven

210T Taffeta uses a plain weave, meaning each weft yarn crosses over and under every warp yarn. This tight structure contributes to its smooth surface and wind-blocking ability. It’s also easier to coat or laminate for waterproofing.

Key Features of 210T Taffeta Fabric

Durability and Strength

Don’t judge by its silky touch—this stuff holds its ground. With tensile strength ranging from 200–350 N (Newton) depending on coating, it’s used in rugged gear that goes through real wear and tear.

- Tear strength: ~10–15 N

- Weight: Around 55-58 GSM (grams per square meter)

- Thickness: Typically 0.10–0.15 mm

Water Resistance and Coating Options

210T on its own isn’t waterproof, but it’s often coated with:

- PU (Polyurethane): Light, flexible, and water-repellent

- PVC (Polyvinyl Chloride): Strong, waterproof, heavier

- Cire Finish: Shiny outwear finish

- Silver or Aluminum coatings: Reflective for thermal insulation

- W/R (Water Repellent) treatment: For quick-drying outerwear

These coatings can raise the hydrostatic head rating up to 800–1500 mm, making it suitable for tents and raincoats.

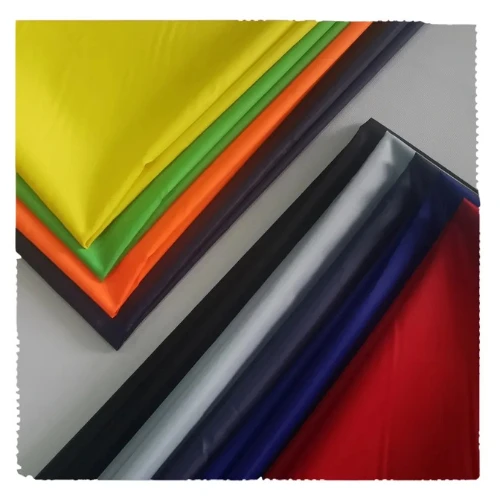

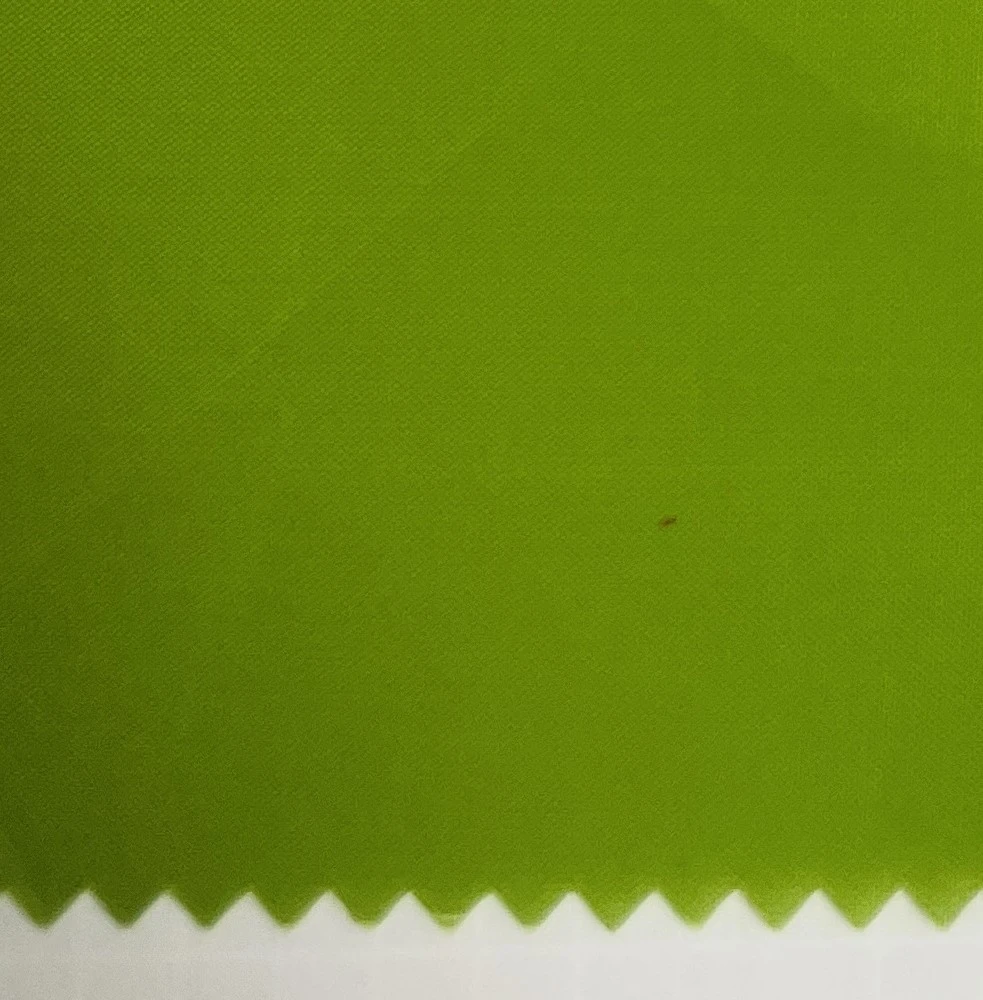

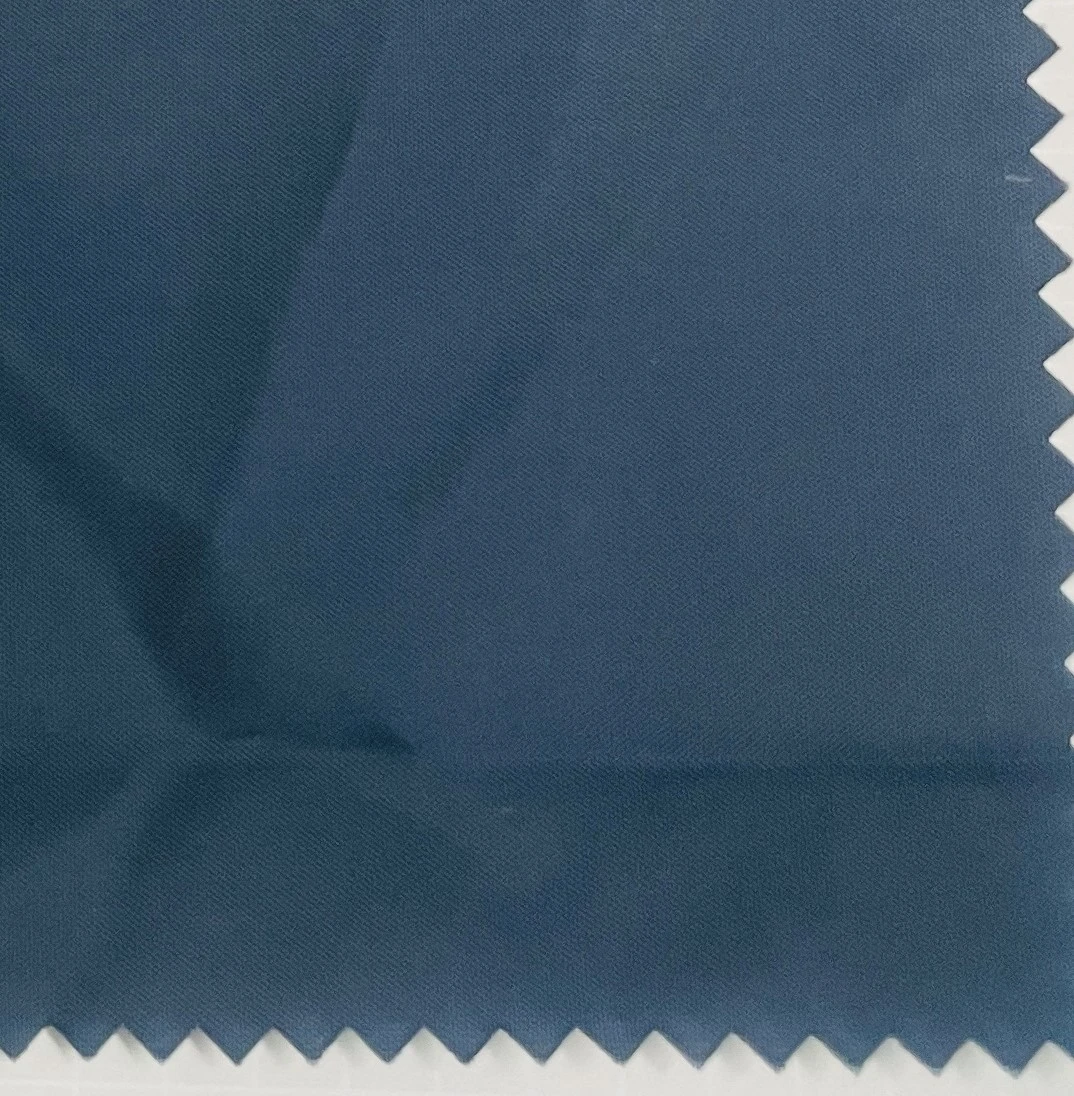

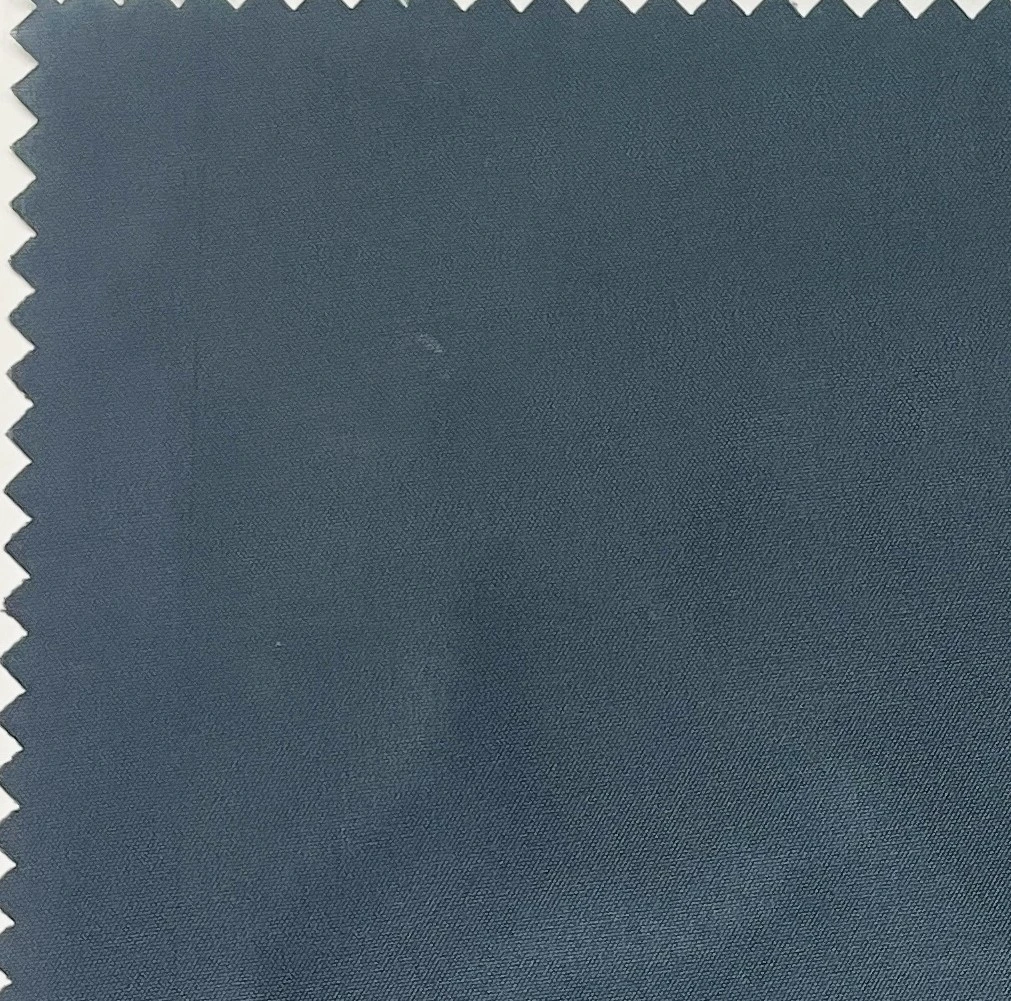

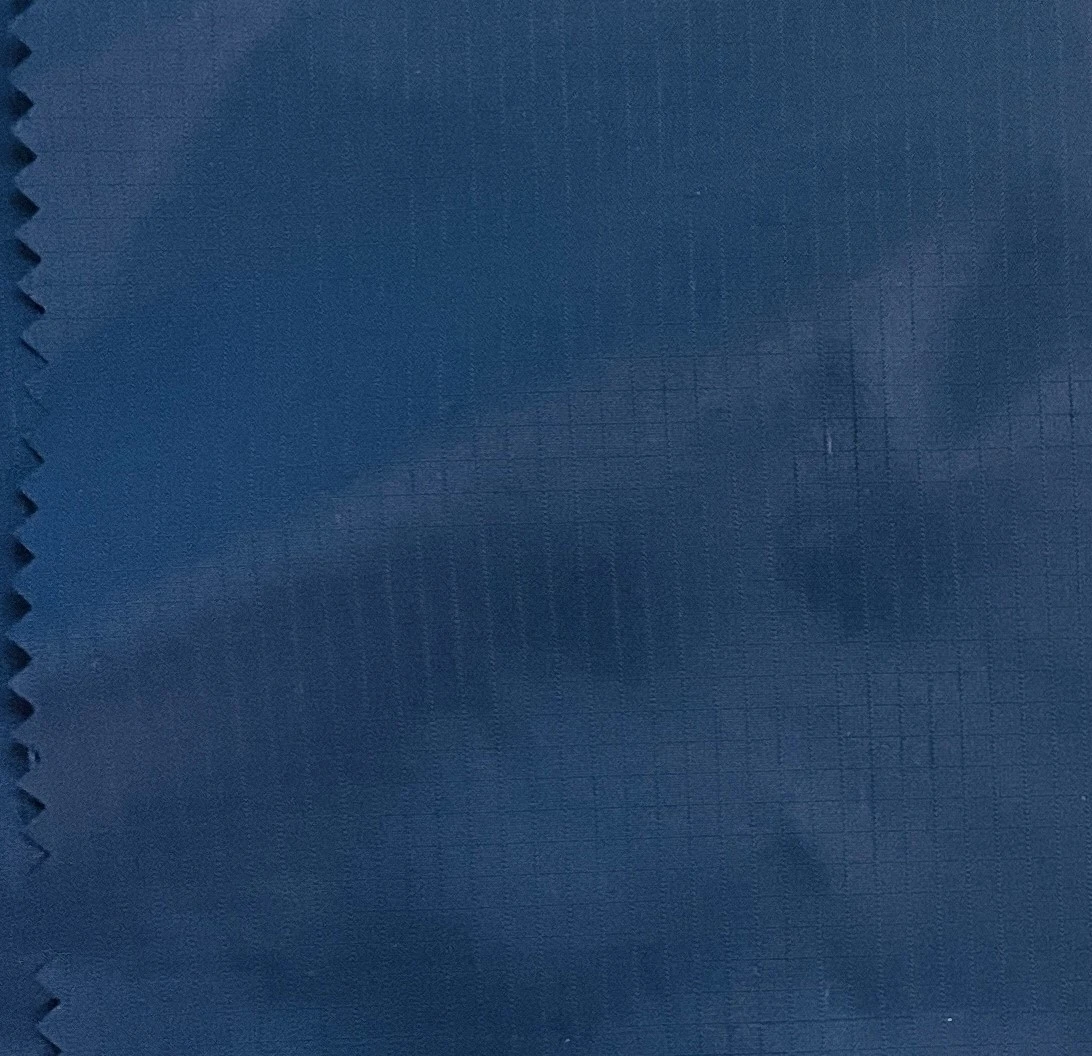

Texture, Appearance, and Color Variety

It has a crisp texture, slight sheen, and high color retention, making it visually appealing. It’s dyed in vibrant tones and often used in contrasting linings or shells for fashion-forward designs.

Common Applications of 210T Taffeta

Outdoor and Technical Gear

- Tents and sleeping bags: Lightweight yet tough

- Raincoats and ponchos: With PU coating, they resist rain

- Windbreakers and jackets: Because wind shouldn’t win

Fashion and Apparel

Designers often use it for:

- Dress linings

- Wind-resistant shells

- Formal wear accessories like ties and sashes

Industrial and Lining Uses

Its affordability and weight make it perfect for:

- Umbrella canopies

- Bag and backpack linings

- Protective covers for machinery

Advantage and Disadvantage of 210T Taffeta

Benefits You Should Know

- Lightweight yet strong

- Water-resistant with coating

- Budget-friendly

- Fast drying

- Available in bulk globally

Limitations to Consider

- Not naturally breathable

- Wrinkles easily

- Melts under high heat

- No stretch (unless blended)

Conclusion

210T Taffeta fabric proves that you don’t need a heavyweight textile to do heavyweight jobs. Whether it’s keeping you dry in the rain or making your gear last longer, this mid-range marvel balances function and affordability like a pro. So next time you touch that silky tent lining or glossy raincoat, you’ll know exactly what’s behind the fabric.

FAQs About 210T Taffeta Fabric

1. Is 210T Taffeta waterproof by itself?

No, but when coated with PU or PVC, it becomes highly water-resistant or waterproof.

2. What’s the difference between 210T and 190T Taffeta?

210T has a higher thread count, meaning it’s denser and more durable than 190T taffeta fabric.

3. Can I use 210T Taffeta for tents?

Yes! Especially when coated, it offers good waterproofing and tear resistance for tent walls or fly sheets.

4. How long does 210T Taffeta last?

With proper care and use, it can last 2–5 years. Mainly depends on the coating and usage conditions.

5. Is 210T Taffeta breathable?

Not naturally. It’s a tight weave. So, airflow is limited unless it’s perforated or blended with breathable fabrics.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.