Modern clothes should be comfortable in all weathers, bright, and convenient, in addition to being attractive. This is particularly important for sports and camp gear, where weight and versatility are essential considerations. Innovative manufacturing helps you to build textile fabrics with new features and capabilities. Based on this consideration, Taslan fabric was developed, which gained additional properties after nylon or polyester fibers were processed.

Table Of Contents

What is Taslan Fabric?

Taslan is polyester or nylon plain fabric woven with 70D DTY filament in warp and 160D ATY yarn in the weft direction. Taslan can also be woven with some variations in weft like 160D single weft, 250D double weft, and 160D*3 three weft. It's a modern, high-tech, tough, long-lasting fabric that's perfect for the gear you'll need any day of the week for your outdoor activities. It dries efficiently and effectively, wicking heat away from the skin, so you don't sweat.

However, it's easy to make Taslan very functional by applying coating materials like Teflon, AC, PU, PVC, and TPU. Thanks to the ease of making it functional, such as waterproof, water resistant, oil and dirt resistant, quick dry, and UV protection, Taslan is becoming much more popular in outerwear, sportswear, casual wear, and swimwear.

What is Taslan Fabric Made of?

Taslan is made of polyamide, nylon, polyurethane, and polyester fibers that help to extend the life of items while also offering warmth and coziness.

Simple woven and plain weave (small jacquard) are also available in this 2/2 twill weave. Nylon Taslan and polyester Taslan are two types of Taslan. Aerodynamic thread is used as the raw material in one direction of the warp and weft.

Taslan Fabric Classification

Based on the raw materials used, Taslan can be categorized mainly into

Polyester Taslan: Polyester Taslan is made of 100% polyester DTY filament. Usually, poly Taslan uses polyester 70D DTY in weft and 160D ATY yarn in the warp direction. The only difference between polyester Taslan and nylon Taslan is the raw materials. Other techniques are almost the same. It's mainly used in making swim shorts, joggers, bags, and outdoor tents.

Nylon Taslan: It's made of 100% Nylon DTY and ATY yarn. The main difference between poly Taslan and nylon Taslan is in hand feel and durability. Nylon Taslan is more durable and softer than polyester. It's widely used in swim shorts, rain jackets, windbreakers and lightweight Jackets, joggers, parachutes, bags, tents, and so on.

Stretch Taslan: The other kind of Taslan is a stretchy. The composition is 95% nylon and 5% spandex, and its weight is around 190 GSM. The most common construction is 70D+40D*320D. Spandex Taslan can be both the warp stretch and the weft stretch. Warp stretch Taslan is the most common one, which is widely used in sportswear and activewear.

Based on structure and design, Taslan can be classified into

Taslan Fabric Properties

The synthetic material Taslan is solid, shaped by rep weaves, and leaves a slight scar on the skin, making it rough to touch. The porous construction allows for thermoregulatory and air circulation, a special polymer coating repels soil and water, and the supporting threads keep their form and do not spread.

The product is invaluable in sports apparel, higher, demi-season (warm) clothing for adults and children due to its combination of properties.

Characteristics of the Taslan fabric

- Yarn Counts:70D and 50D filaments for the warp and wefts are made with 160D, 250D, 320D,450D, and 600D. And other nylon air-textured yarns in single, double, and three wefts (160D).

- Thread Density: The three most common densities are 190T, 228T, 240T and 260T Taslan.

- Weight: It varies between 100 and 190 GSM, with the most common weight range being 100 to 110 GSM.

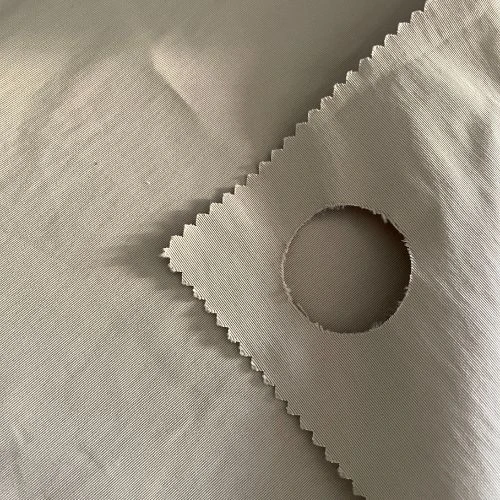

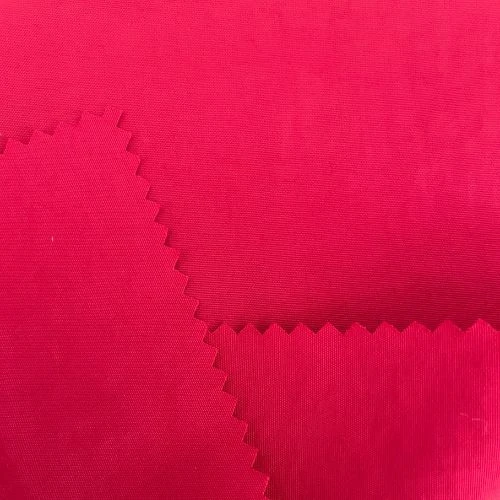

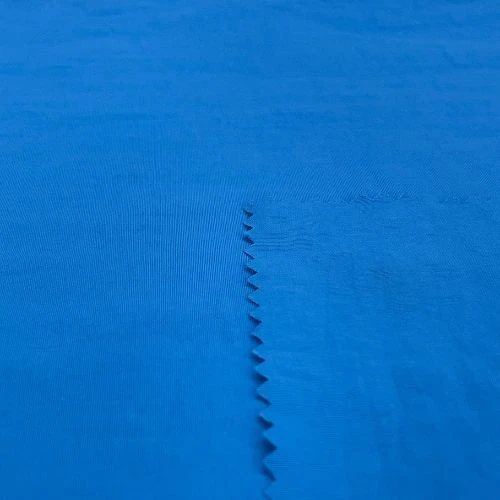

- Appearance: Taslan has a naturally crinkled surface.

- Breathability: The porous surface allows for breathability and produces a microenvironment, making the Fabric hygroscopic and lightweight.

- Functionality: Taslan can be made multi-functional by applying coatings such as PU, AC, PVC, and so on.

- Solubility: Taslan fabric is made of high-density fiber that is light in weight. They're both chemical and natural-solvent-resistant.

- Colors: This Fabric has a pleasing appearance and comes in a variety of colors. It's easy to manage and sew, and the edges don't appear when you open it.

- Sewing Characters: Taslan is a brand of not-so-cheap tissues, and its production necessitates the use of a particular sewing machine. Since there is mild rustling while driving, the area of service is negligible.

What is Taslan fabric used for?

Taslan is suitable for items with certain fillers. It is ideal for casual sportswear, adventure sports, and outdoor activities, as it provides reliable protection from wind, fog, snow, ice, and heat. The material's reinforced inseminated fiber helps you to be outdoors in whatever season and feel safe in the fresh air.

Overalls, gloves, winter clothing, raincoats, and raincoats are sturdy, don't restrict mobility, keep moisture out, and the Taslan creates a microclimate that prevents an active, mobile child from excessive heat or cooling. Dirt, stains, and dust are simple to clean at home.

Taslan is frequently used in furniture production. Sofas, padded stools, and armchairs made of cloth with artificial fabrics that do not lose their form like Taslan are easy to wash and beautify the furniture. The product is impregnated to protect it from stains, debris, and moisture.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.