Meshes are categorized based on material, weave pattern, and application. Some of the most commonly used types include:

Table Of Contents

- 1x1 Mesh –

- 2x2 Mesh –

- 4x4 Mesh –

- Hole Mesh –

- Pin Hole Mesh –

- Knit Air Mesh –

- Power Mesh –

- Mini Mesh –

- Peach Mesh –

- Dobby Mesh

- Pique Mesh

- Woven Wire Mesh –

- Knitted Wire Mesh –

- Hard Mesh –

- Expanded Metal Mesh –

- Fiberglass Mesh –

- Manufacturing Process of Different Mesh Types

- Applications of Various Mesh Types Garments

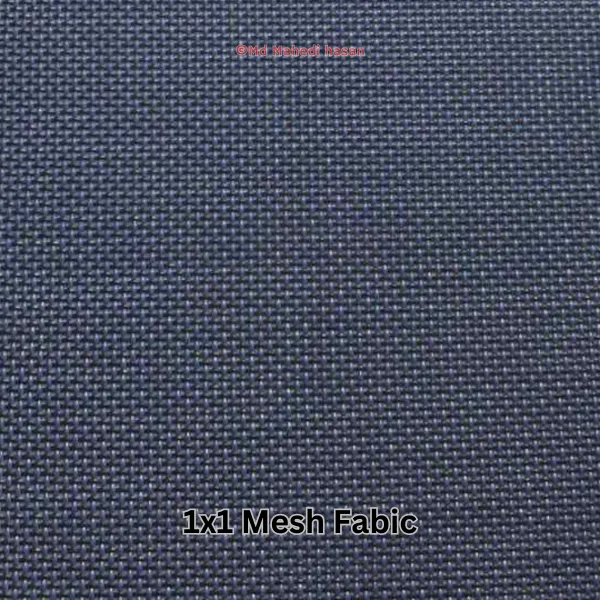

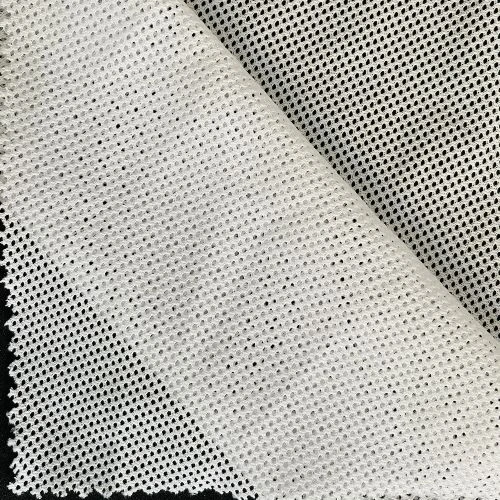

1x1 Mesh –

1x1 mesh fabric features a uniform grid pattern. Each hole is formed by 1 warp and 1 weft yarn, with one opening per linear inch.

GSM: 80-150, HPI: 1, Yarn Count: 30s-40s.

1x1 mesh is commonly used in lining garment reinforcement.

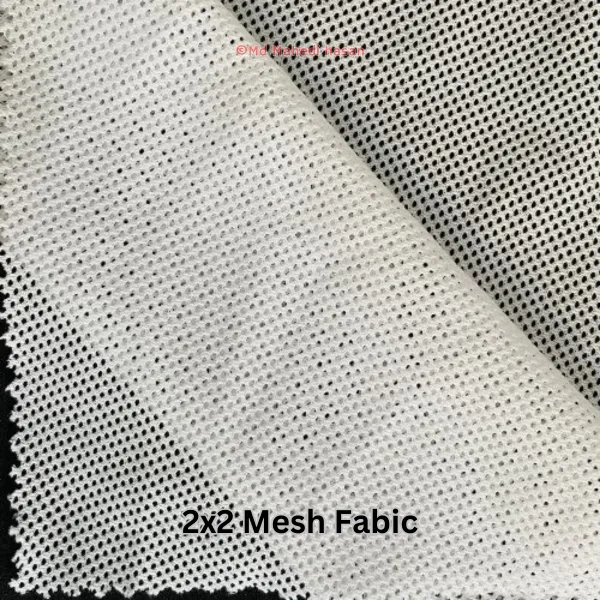

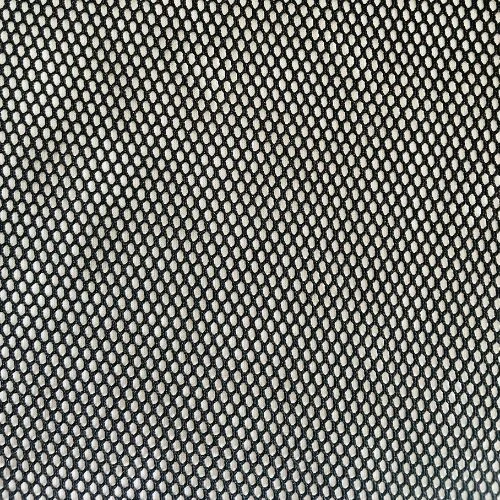

2x2 Mesh –

A strong and durable option with each hole formed by 2 warp and 2 weft yarns. It has two openings per linear inch.

GSM: 100-200, HPI: 2, Yarn Count: 20s-30s.

2x2 mesh fabric is used in sportswear and breathable fashion fabrics.

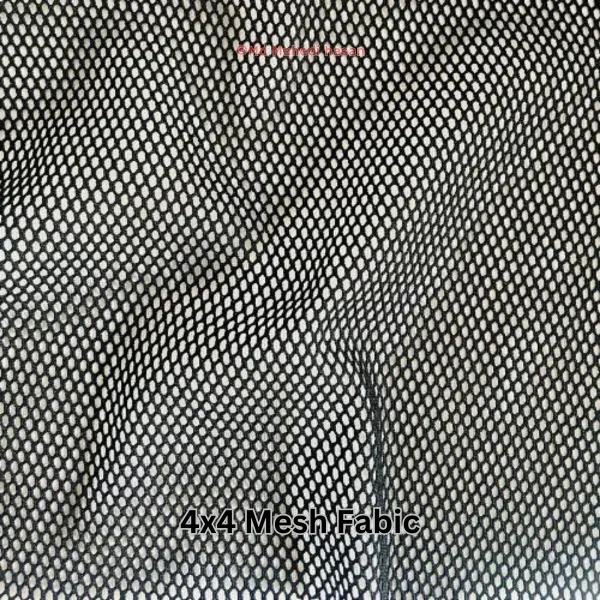

4x4 Mesh –

Features four openings per linear inch, offering a balance of strength and ventilation.

GSM: 120-250, HPI: 8-10, Yarn Count: 10s-20s.

4x4 mesh fabric is used in activewear and lining materials.

Hole Mesh –

A generic term for meshes with various hole sizes.

GSM: 80-180, HPI: Varies, Yarn Count: 30s-50s. Used in breathable clothing and aesthetic fashion elements.

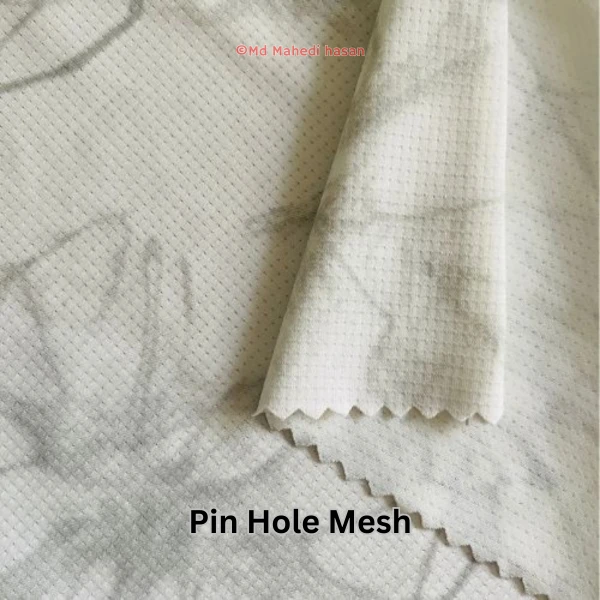

Pin Hole Mesh –

Pinhole features excellent holes for high-precision applications. Its GSM is 60-150, HPI is 10-30, and Yarn Count is 40s-60s. It is used in lightweight and stylish apparel.

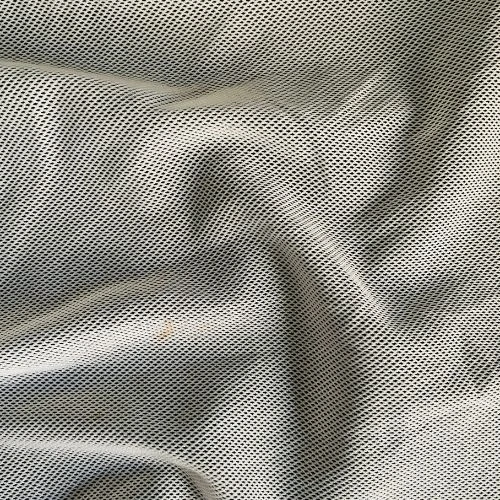

Knit Air Mesh –

A breathable and flexible material. It looks like bonded, but the construction is not bonded.

GSM: 150-300, HPI: 2-5, Yarn Count: 20s-40s.

Knit air mesh fabric is used in sports shoes, performance wear, and mesh paneling.

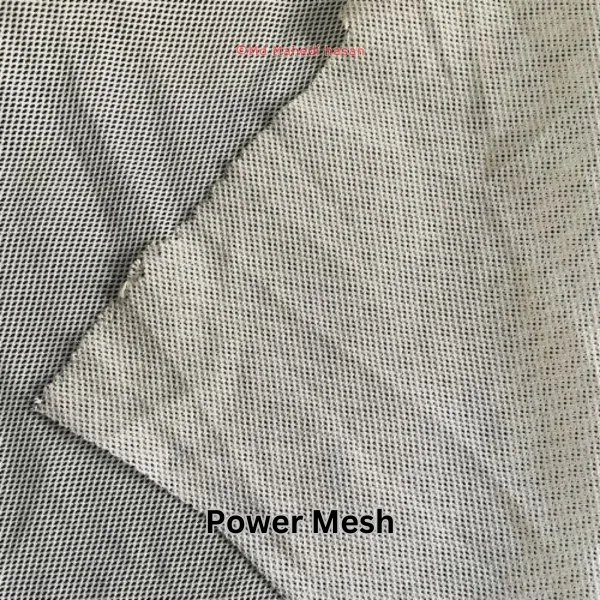

Power Mesh –

A strong, elastic mesh. Has a distinguished rectangular shape. GSM: 60-250, HPI: 6-12, Yarn Count: 30s-50s. Usually, power mesh is in ladies' shapewear, lingerie, and compression garments.

Mini Mesh –

A fine, small-patterned mesh. GSM: 80-160, HPI: 8-16, Yarn Count: 40s-60s. Great for athletic wear, jerseys, and fashion overlays.

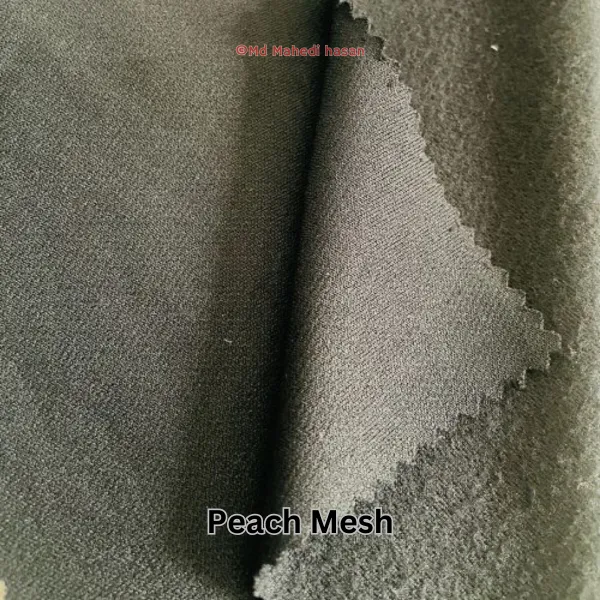

Peach Mesh –

Highly small perpetrated. Soft-textured mesh.

GSM: 140-180,

HPI: 5-12,

Yarn Count: 30s-50s.

Peach Mesh: Used for lingerie, intimate wear, and lightweight fashion apparel.

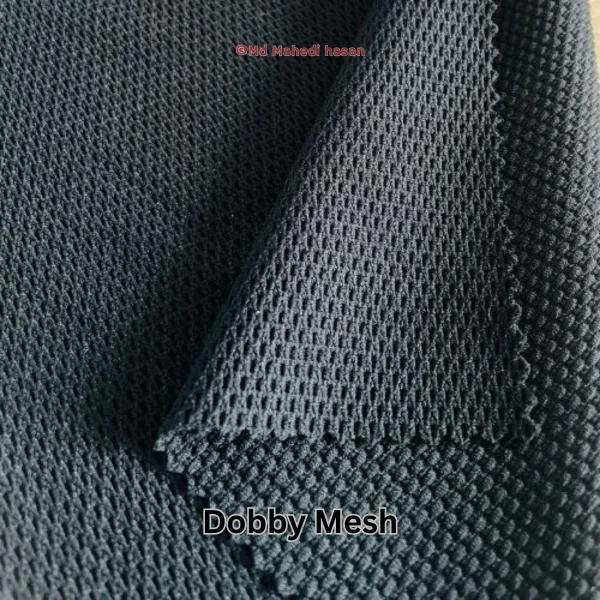

Dobby Mesh

Dobby mesh is woven with intricate patterns. Its GSM is 120-250, HPI is Variable, and the Yarn Count is 20s-40s. It adds aesthetic appeal to high-end garments and casual wear.

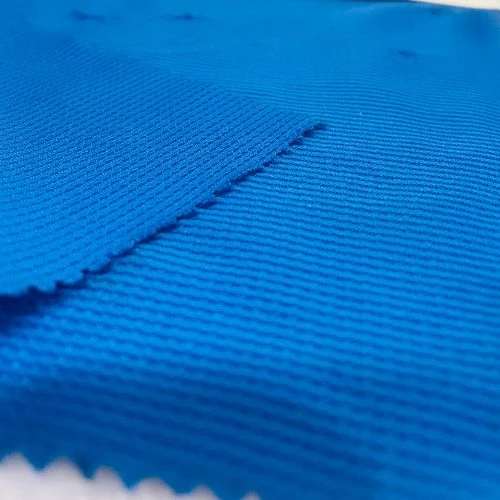

Pique Mesh

– A textured fabric. GSM: 160-280, HPI: 3-8, Yarn Count: 20s-30s. Commonly used in polo shirts, sports jerseys, and breathable summer wear.

Woven Wire Mesh –

Made by interlacing fibers. GSM: 150-350, HPI: Varies, Yarn Count: 10s-20s. Used in innovative fashion designs.

Knitted Wire Mesh –

A flexible and lightweight mesh. GSM: 120-300, HPI: Varies, Yarn Count: 20s-40s. Incorporated in stretchable fabrics for comfort wear.

Hard Mesh –

Made from polyethylene or polypropylene. GSM: 200-500, HPI: Varies, Yarn Count: Not applicable. Used in structured handbags, footwear, and decorative fashion elements.

Expanded Metal Mesh –

Simulated in textiles. GSM: 200-400, HPI: Varies, Yarn Count: 10s-20s. Used for structured fashion designs and futuristic garments.

Fiberglass Mesh –

Occasionally used in fashion accessories. GSM: 250-400, HPI: Varies, Yarn Count: Not applicable. Reinforces textiles without adding bulk.

Manufacturing Process of Different Mesh Types

Mesh manufacturing involves various techniques, including:

- Weaving – Used for woven wire, dobby, and pique mesh.

- Knitting – Utilized for knitting air mesh and power mesh.

- Perforation – Creating holes in fabric sheets for breathable mesh fabrics.

- Expansion – Creating 3D textures and structured mesh designs.

- Molding & Extrusion – Used for plastic and fiberglass mesh in fashion accessories.

GSM (Grams per Square Meter) and Its Importance

GSM measures the density of the mesh material. It is calculated as:

Higher GSM indicates a heavier, denser mesh, suitable for supportive and compression garments, while lower GSM is used for breathable and lightweight fashion applications.

HPI (Holes per Inch) and Mesh Count

HPI refers to the number of holes in a linear inch of mesh. It determines:

- Breathability & Comfort – Higher HPI meshes allow for greater airflow, making them ideal for sportswear and summer wear.

- Stretch & Flexibility – Lower HPI meshes, often paired with elastane, provide stretch in compression and performance wear.

- Strength & Support – Lower HPI with denser fibers enhances durability in shapewear and reinforcement fabrics.

Applications of Various Mesh Types Garments

Each type of mesh serves distinct purposes in fashion:

- 1x1, 2x2, and 4x4 Mesh – Used in sportswear, jackets, and high-performance fabrics.

- Pin Hole Mesh & Hole Mesh – Utilized in aesthetic overlays, breathable linings, and avant-garde fashion.

- Knit Air Mesh & Power Mesh – Ideal for sneakers, performance wear, and shapewear.

- Mini Mesh & Peach Mesh – Used in lingerie, soft-textured fashion, and lightweight tops.

- Dobby Mesh & Pique Mesh – Adds texture and breathability to polo shirts, activewear, and casual fashion.

- Filtration Mesh – Used in fabric innovation for moisture-wicking and sweat-resistant properties.

- Security Mesh – Adapted in protective wear and reinforced sports apparel.

- Reinforcement Mesh – Integrated into structured garments like corsets and high-strength bodysuits.

- Acoustic Mesh – Designed to create sound-responsive fashion pieces.

- Heat-Resistant Mesh – Used in protective fashion and high-performance outerwear.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.