Table Of Contents

What is Interlock Fleece Fabric?

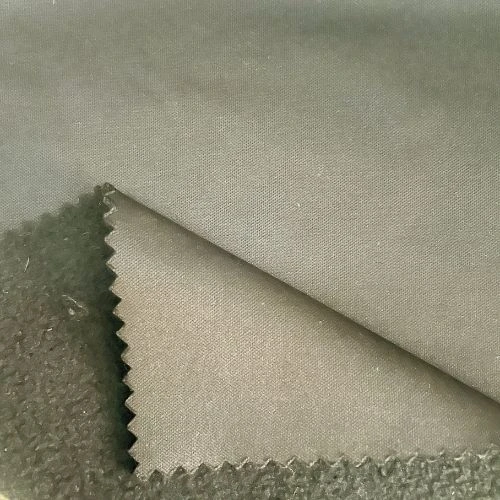

Interlock fleece fabric is a double-knit fabric brushed on the face, back, or both sides. Generally, interlock fabric has a technical face (V-shape) on both sides, which means the same appearance in front and back. However, interlock fleece is brushed to enhance its smoothness, soft surface, and insulating properties.

Interlock fabric is crafted using a unique interlocking weave pattern, which gives it a dense yet flexible structure. It’s thicker and sturdier than single jersey fabrics.

|

Characteristics |

Details |

|

Also Known As |

Double-knit fleece, Brushed fleece |

|

Manufacturing Process |

Interlock knitting, brushing |

|

Appearance |

Smooth outer surface, brushed soft inner fleece |

|

GSM Range |

200–350 GSM |

|

Composition Range |

100% Polyester, Polyester-Cotton blends (70:30, 60:40) |

|

Construction Range |

Dense double-knit interlock structure |

|

Functionality |

TPU, PU, AC, W/R, PV, PVC |

|

Thread Density Range |

190T–320T |

|

Count Variations |

30D, 50D, 75D, 150D |

|

Full Width |

57/58”, 59/60”, 71/73” |

|

Fabric Breathability |

Moderate |

|

Moisture-Wicking Abilities |

Moderate to High (depends on finish) |

|

Heat Retention Abilities |

High (excellent for cold climates) |

|

Stretchability |

Moderate to High (10–20%) |

|

Prone to Pilling/Bubbling |

Low (resists pilling better than single-knit fleece) |

|

Country of First Production |

United States (Late 20th Century) |

|

Biggest Exporter Country |

China (Exports over 2 billion meters annually) |

|

Recommended Washing Temperatures |

Cold to warm water (30°C–40°C) |

|

Applications |

Activewear, casual clothing, sportswear, linings for jackets and gloves, industrial uses |

How is Interlock Fleece Fabric Made?

Interlock fleece fabric uses tightly knit polyester or a polyester-cotton blend. Here's manufacturing process:

- Knitting Process: The interlock method knits two layers of fabric simultaneously, creating a double-faced material.

- Brushing: The fleece side undergoes brushing, making it soft and fluffy.

- Dyeing: Fabrics are dyed in various colors, depending on the final use.

Key Features of Interlock Fleece Fabric

1. Excellent Stretchability

Thanks to its interlocking weave, this fabric stretches both horizontally and vertically. It offers a snug fit. It has a 10–20% elasticity. Which is ideal for sportswear.

2. Superior Warmth Retention

Interlock fleece traps air between its layers. This property enhances insulation, and retain body heat during colder months.

3. High Durability

It withstands regular wear and tear. Its double-knit structure resists pilling and fraying better than other fleece types.

Applications of Interlock Fleece Fabric

The applications of interlock fleece fabric are versatile:

- Activewear: Tracksuits, leggings, and gym clothes benefit from its stretch and durability.

- Casual Clothing: Hoodies, sweatshirts, and pajamas feel cozy and warm.

- Industrial Uses: Used in linings for jackets, gloves, and workwear for added warmth.

Benefits of Using Interlock Fleece Fabric

1. Comfort and Softness

The brushed fleece side feels plush, making it skin-friendly. You’ll enjoy wearing it all day long.

2. Versatility

It suits everything from athleisure to outdoor apparel. Its structure adapts to various sewing needs.

3. Cost-Efficiency

Interlock fleece fabric offers quality at an affordable price. It is budget-friendly compared to pure wool alternatives.

Conclusion

Interlock fleece fabric is the ultimate blend of comfort, warmth, and durability. Whether for sportswear or casual outfits, this fabric never disappoints. If you’re looking to combine affordability with functionality, interlock fleece should be your go-to choice.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.