When it comes to durable, tear-resistant fabrics, ribstop has become a go-to material for a variety of applications. Whether for outdoor gear, military clothing, or sportswear, ribstop fabric is designed to withstand tough conditions. But what makes it so strong, and how is it constructed?

Let’s know the details of ribstop fabric including the construction process, and why it stands out.

Table Of Contents

What is Ribstop Fabric?

Ribstop, or “ripstop,” fabric is a woven fabric with a special reinforcing rib pattern. The rib grid pattern makes it resistant to tearing. It was originally developed for military uniforms.

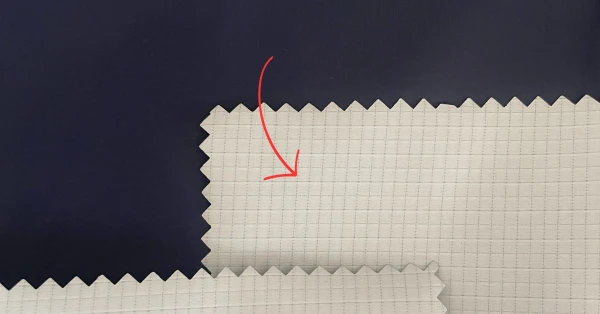

Figure: Mini Rib Grid Pattern in Fabric Construction

Ribstop has gained popularity in garment industries due to its robust yet lightweight properties. The unique grid pattern gives ribstop its signature look and helps prevent small tears from growing larger.

|

Category |

Details |

|

Fabric also known as |

Reinforced grid fabric, Anti-tear fabric, Rip-resistant fabric |

|

Manufacturing Process |

Woven construction with a reinforced grid pattern, using thicker threads at intervals in warp and weft directions |

|

Appearance |

Checkerboard or crosshatch pattern visible on the surface, smooth texture |

|

GSM Range |

30 - 120 GSM (varies based on material and use case) |

|

Composition Range |

100% nylon, 100% polyester, 100% cotton, or blends (typically nylon/polyester) |

|

Construction Range |

Plain or basket weave; reinforced grid pattern with higher-tenacity threads |

|

Functionality |

TPU, PU, AC, W/R (water-resistant), PV, PVC coatings (varies by application) |

|

Thread Density Range |

190 - 400 TPI (threads per inch) |

|

Count Variations |

Commonly 40D, 70D, 210D, 420D, 600D, and higher (denier) |

|

Full Width |

Typically 57/58 inches or 59/60 inches |

|

Cuttable Width |

54 - 58 inches (depending on selvage) |

|

Fabric Breathability |

Moderate (varies by composition; nylon and polyester versions less breathable than cotton) |

|

Moisture-Wicking Abilities |

Moderate to high for polyester versions; cotton versions less moisture-wicking |

|

Heat Retention Abilities |

Moderate; synthetic versions provide better insulation compared to cotton |

|

Stretchability |

Generally non-stretch, unless blended with elastane or spandex |

|

Prone to Pilling/Bubbling |

Low pilling tendency; synthetic versions are more resistant to pilling |

|

Country of First Production |

United States (1940s, originally developed for military use) |

|

Biggest Exporting Country |

China (largest producer and exporter of ripstop fabric today) |

|

Recommended Washing Temps |

30 - 40°C for synthetic ripstop; 40°C for cotton ripstop |

|

Applications |

Outdoor gear (tents, sleeping bags), military uniforms, backpacks, jackets, workwear, fashion items, sports apparel, and tarps |

Types of ribstop Fabric

Nylon ribstop

Nylon ribstop is known for its lightweight yet durable qualities. It’s highly resistant to abrasion and is commonly used in outdoor gear like tents, backpacks, and jackets.

- Weight: Ranges from 30-70 GSM.

- Strength: Can withstand high-stress applications due to nylon’s natural flexibility.

Polyester ribstop

Polyester ribstop offers UV resistance and durability, making it ideal for items exposed to sunlight. This version is often used in applications like tarps and outdoor banners.

- Weight: Averages 50-90 GSM.

- UV Resistance: Higher than nylon, which makes it a great choice for sun exposure.

Cotton ribstop

Cotton ribstop is softer and more breathable, making it suitable for workwear and casual apparel. While it’s not as tear-resistant as nylon or polyester, it offers a balance of comfort and durability.

- Weight: Between 80-120 GSM.

- Application: Used in clothing where comfort is as important as durability.

The Construction of Ribstop Fabric

The magic of ribstop fabric lies in its construction. It is woven in a way that incorporates thicker threads at regular intervals. It creates a grid or “rib” pattern. This structure reinforces the fabric and distributes any pressure or strain over a larger area. Therefore it can minimize the risk of tears.

Step 1 - Selecting the Fibers

- Nylon – Known for its strength and resilience

- Polyester – Lightweight, affordable, and durable

- Cotton – Often blended with synthetics for added comfort and strength

Nylon-polyester blends are popular in outdoor clothing, while cotton blends are often preferred for everyday apparel.

Step 2 - Weaving the Fabric

After selecting the fibers, the weaving process begins. Ribstop fabric is woven using a plain weave pattern with thicker yarns interwoven at intervals of 5 to 8 millimeters. This weaving technique forms a crosshatch pattern that reinforces the fabric.

- Base Weave: The base fabric is typically a lightweight material woven in a plain weave. It provides flexibility and breathability.

- Reinforcement Grid: Thicker, higher-tensile threads are woven into the base fabric at fixed intervals. It creates a distinctive ribstop grid pattern.

These thicker threads act like “mini barriers” against tearing. When a tear begins, the reinforced grid resists further ripping by containing the tear within one section, thereby preventing it from spreading.

Step 3 - Adding Finishes

Once the fabric is woven, manufacturers often apply finishes to enhance its performance. Common finishes include:

- Water Resistance: By adding a water-repellent coating, ribstop fabric can resist moisture. That makes it ideal for outdoor applications.

- UV Protection: Some ribstop fabrics are treated to block harmful UV rays, protecting users in sunny conditions.

- Flame Retardant: For specific applications like military or industrial use, ribstop may be treated with flame-retardant chemicals.

Each finish adds another layer of protection, making ribstop versatile and adaptable for various uses.

Properties of Ribstop Fabric

Ribstop fabric construction gives it unique properties that set it apart from other materials. Here’s a closer look at what makes ribstop so effective:

-

i. Tear Resistance

-

The most distinctive feature of ribstop is its tear resistance. Thanks to its reinforced grid, even if a tear starts, it’s unlikely to spread. Studies show that ribstop fabric can handle up to 25% more tensile stress compared to non-reinforced fabrics of similar weight.

-

ii. Lightweight and Flexible

-

Despite its strength, ribstop remains lightweight. Most ribstop fabrics weigh between 60 to 120 grams per square meter (gsm).

-

iii. Breathable and Comfortable

-

Ribstop is commonly woven with breathable fibers like nylon or polyester. It allows for airflow and temperature control. This is crucial for outdoor and active wear, as it prevents overheating and keeps users comfortable.

-

iv. Weather Resistance

-

Ribstop fabrics are frequently treated with waterproof coatings, to make them weather-resistant. This adds an extra layer of durability. It provides the fabric to withstand rain, snow, and wind, which is why ribstop is used extensively in tents, jackets, and even parachutes.

Applications of Ribstop Fabric

a) Outdoor Gear

One of the most popular uses of ribstop fabric is in outdoor gear, including tents, backpacks, and sleeping bags. Its lightweight, durable nature makes it ideal for rugged outdoor conditions, where it needs to withstand wear and tear without adding extra weight.

b) Sportswear and Activewear

Ribstop is also common in sportswear, particularly in jackets, pants, and raincoats. Its weather-resistant and breathable properties make it ideal for athletic activities, allowing for both comfort and durability.

c) Military and Tactical Applications:

Due to its origins, ribstop is still used extensively in military uniforms and gear. The tear-resistant construction offers extra protection in rough environments, while the lightweight nature of the fabric ensures mobility.

d) Fashion and Everyday Apparel

Today, ribstop is finding its way into fashion, often used in jackets, pants, and even shoes. Its signature grid pattern adds a stylish texture, making it a trendy choice for everyday clothing.

Advantages of Ribstop Fabric

The popularity of ribstop fabric comes down to its practical benefits. Here’s a quick summary:

- Durability: The reinforced grid pattern provides extra tear resistance.

- Lightweight: Weighing between 60 to 120 gsm, ribstop is incredibly light.

- Weather Resistance: Treated to resist water and UV rays, making it suitable for outdoor conditions.

- Versatile Applications: Suitable for a wide range of uses, from sportswear to military gear.

- Comfort: Breathable and flexible, making it comfortable for prolonged wear.

Conclusion

The ripstop fabric has transformed the world of textiles with its unique construction and versatility. Thanks to its reinforced grid, ribstop offers a level of durability and resistance that is unmatched, making it a staple in everything from outdoor gear to fashion.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.