Let’s not overcomplicate things. 1050D Oxford fabric is a heavy-duty woven textile, mostly made from nylon 6,6 or polyester, with a denier rating of 1050. Now, if “denier” sounds fancy, it just refers to the thickness of the yarn. The higher the number, the thicker the yarn. So, 1050D? Pretty beefy.

|

Specification |

Details |

|

Also Known As |

Heavy-Duty Oxford, Ballistic Oxford, 1050 Denier Fabric |

|

“X” Manufacturing Process |

Woven (Plain/Basket Weave) → Heat Setting → Dyeing → Functional Coating (PU/PVC/TPU/AC) |

|

Appearance |

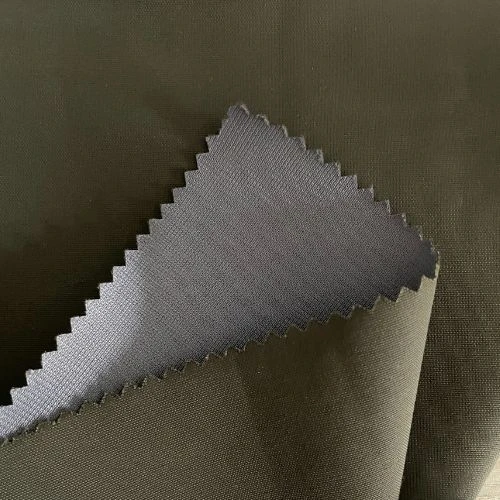

Matte or semi-glossy surface (based on coating), slightly textured basket weave |

|

GSM Range |

280 – 450 GSM (coated version may exceed 500 GSM) |

|

Composition Range |

100% Nylon 6,6 (most common), some variants in Polyester or Recycled Nylon |

|

Construction Range |

1050D x 1050D, Warp and Weft balanced (Plain or 2x2 basket weave) |

|

Functionality (Finishes) |

TPU, PU, PVC, AC (Acrylic), WR (Water-Repellent), PV (Polyvinyl), Anti-UV, Mildew-Resistant, Fire Retardant (FR) options available |

|

Possible Yarn Count |

1050D filament (9.3 tex), multifilament nylon; some blends with 840D or 1200D variants |

|

Full Width |

Common: 57/58", 59/60"; Special: 71/73" for industrial coating |

|

Fabric Breathability |

Low (especially when coated); improved with WR or uncoated nylon |

|

Stretchability |

Very Low (non-stretch woven); minimal elasticity in both warp and weft |

|

Prone to Pilling/Bubbling |

No pilling; low bubbling risk (if heat-treated and properly coated) |

|

Country of Origin (Year) |

USA, developed during 1960s for military ballistic textiles (ballistic nylon evolution) |

|

Biggest Exporter Country |

China (Est. 2023 Export: ~68,000 MT/year, especially from Zhejiang and Fujian provinces) |

|

Recommended Washing Temp. |

Cold to Warm Wash (30–40°C); avoid hot water to prevent coating degradation |

|

Finishing Uses to Increase Functionality |

Flame Retardant Finish, Anti-UV, Anti-Static, PU+WR dual coatings, TPU lamination for high elasticity |

|

Water Resistance Level |

PU Coated: 600–1,000 mm Hâ‚‚OPVC Coated: 1,000–3,000 mm Hâ‚‚OTPU: 3,000+ mm (High Hydrostatic Pressure) |

|

Abrasion Resistance |

Excellent (>20,000 cycles in Martindale test for nylon version) |

|

Tensile Strength |

3000–4500 N (warp & weft combined, depending on weave and coating) |

|

Tear Strength |

80–150 N (ASTM D2261, varies by coating) |

|

UV Resistance |

Moderate without treatment; High with UV coating |

|

Flame Resistance |

Optional FR coating meets CPAI-84 / NFPA 701 standards |

|

Chemical Resistance |

Moderate (uncoated), High with PVC or TPU coating |

|

Shrinkage Rate |

Minimal (<2%) when heat-set and coated |

|

Color Fastness |

4–5 Grade (with proper dyeing and coating) |

|

Eco-Friendly Options |

Recycled nylon versions emerging (GRS certified); Bio-based coatings under R&D |

|

Applications |

Tactical & military backpacks, motorbike bags, tool pouches, protective covers, industrial aprons, rugged tents, camping gear, military footwear, protective luggage, tarpaulins, dog harnesses, boat covers |

This fabric stands out for its extreme durability, abrasion resistance, and water-repellent finishes, which makes it a solid choice for rough outdoor environments and military-grade gear. If you’ve ever carried a tactical backpack that feels like it could survive a zombie apocalypse, odds are it was made from 1050D Oxford.

Table Of Contents

Key Features of 1050D Oxford Fabric

Denier Rating and Thickness

The "1050D" means 1050 denier, which is thick. Compared to standard 210D or 420D fabrics, this one’s almost five times thicker, giving it a rugged feel and strong resistance against tearing or puncturing.

In real numbers, 1050D fabrics are typically 0.45 to 0.6 mm thick.

GSM and Weight Range

This fabric usually weighs between 280 to 450 GSM (grams per square meter). That makes it heavier than other Oxfords like 600D or 420D, but with that weight comes greater strength.

Weave Pattern and Surface Appearance

Oxford weave is a variant of plain weave. It features a slightly textured, basket-like pattern. The 1050D variant often appears matte but can be shinier with PU or PVC coatings. It's not the fabric you wear to brunch—unless your brunch includes rock climbing.

Composition and Manufacturing Process

Nylon vs Polyester Variants

Although 1050D can be made from either polyester or nylon, nylon is more common for this denier level. Why?

- Nylon 6,6 has better tensile strength—around 9.5g/denier, while polyester sits lower at 7g/denier.

- Nylon also has higher abrasion resistance, which is crucial for tactical or survival gear.

Coatings and Functional Treatments

Manufacturers love giving 1050D Oxford a makeover:

- PU (Polyurethane) – water-resistant and flexible

- PVC (Polyvinyl Chloride) – thick, glossy, more waterproof but heavier

- TPU (Thermoplastic Polyurethane) – high-end, elastic, and resistant to cold

- WR (Water Repellent) or AC (Acrylic Coating) – light protection, ideal for bags

Coated versions are often 30–50% heavier than uncoated ones, but they add waterproofing and chemical resistance.

Common Uses of 1050D Oxford Fabric

Outdoor and Tactical Gear

This is where 1050D flexes. It’s the go-to material for:

- Military backpacks

- Tactical vests

- Tent flooring

- Climbing gear

It’s resistant to abrasion, UV rays, and tearing, which is exactly what survivalists and military personnel need.

Heavy-Duty Bags and Luggage

If you’ve ever dragged a bag across gravel, thrown it onto a bus roof, and still used it five years later—it’s probably 1050D.

- Rolling luggage

- Laptop bags

- Motorcycle saddlebags

- Duffel bags

Industrial and Protective Covers

Not just for the adventurers—1050D finds its way into:

- Equipment covers

- Truck tarps

- Heavy-duty upholstery

- Tool belts and aprons

Fun fact: Some waterproof marine seat covers also use 1050D because of its toughness and UV protection.

Pros and Cons of 1050D Oxford Fabric

|

Pros |

Cons |

|

Extremely durable |

Heavier than other fabrics |

|

Water and abrasion resistant |

Not very breathable |

|

Good chemical resistance with coating |

Limited stretch |

|

Long lifespan in rough use |

Can be expensive |

Think of it like a tank—it’s not sleek, but it’s built to last.

Final Thoughts

1050D Oxford fabric is a powerhouse. Whether you’re gearing up for a mountain hike, building tactical gear, or covering your boat, this fabric brings performance where it counts. It may not win beauty contests, but when the going gets tough, 1050D doesn’t flinch.

It’s a balance of strength, structure, and adaptability—no fluff, just fabric that works as hard as you do.

FAQs About 1050D Oxford Fabric

1. Is 1050D Oxford better than 600D?

Yes. It's stronger, thicker, and more resistant to wear. But it’s also heavier, so it's best for gear that needs maximum durability.

2. Can 1050D Oxford fabric be waterproof?

On its own, it’s water-resistant. But when coated with PU or PVC, it becomes waterproof.

3. Is it safe to use 1050D Oxford in extreme weather?

Yes. Coated variants perform well in cold, wet, and sunny conditions. It holds up better than most mid-range fabrics.

4. What does “D” stand for in 1050D?

“D” stands for Denier, which measures the thickness of yarn. The higher the number, the thicker and stronger the fiber.

5. Is 1050D Oxford eco-friendly?

Not really. Most versions use synthetic fibers and chemical coatings, but some manufacturers are now experimenting with recycled nylon.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.