You’ve probably seen 300D Oxford fabric used in backpacks, jackets, or even tents, but what actually is it? In simple terms, 300D Oxford fabric is a type of woven polyester or nylon material that blends durability and lightweight performance. The “D” stands for denier, which we’ll get into shortly. This fabric shows up in a lot of products because it's strong, water-resistant, and not too heavy.

|

Parameter |

Specification / Description |

|

Also Known As |

300 Denier Oxford, 300D Polyester Oxford, Mid-Weight Oxford Fabric |

|

Manufacturing Process |

Woven (Plain or Basket Weave) → Dyeing → Coating (PU/PVC/TPU/AC) → Finishing |

|

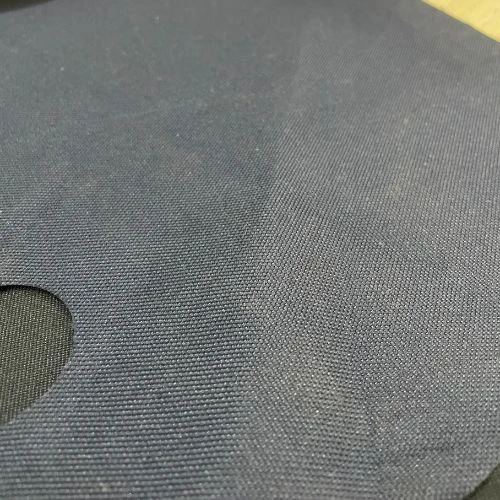

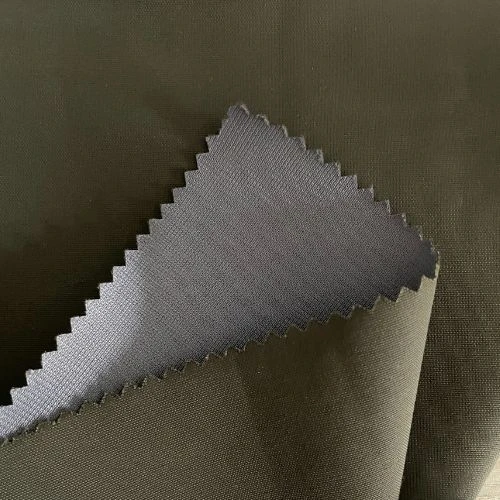

Appearance |

Matte or semi-gloss surface, tightly woven texture, smooth with a subtle criss-cross pattern |

|

GSM Range |

130 – 250 GSM (depends on coating type and finish) |

|

Composition Range |

100% Polyester or Nylon (typically Polyester for 300D) |

|

Construction Range |

300D x 300D, 300D x 500D, 300D x 600D (warp x weft) |

|

Functionality Coatings |

PU, PVC, TPU, Acrylic (AC), Water Repellent (W/R), Milky Coating, Silver Coating |

|

Possible Yarn Count |

300D/96F, 300D/144F (filament yarns; F = filaments per yarn) |

|

Full Width |

57/58", 59/60", 61/62", 71/73" (varies based on supplier and finish) |

|

Fabric Breathability |

Moderate (Better with PU, Poor with PVC) |

|

Stretchability |

Non-stretch; slight mechanical stretch (if calendered or bonded with spandex layer) |

|

Prone to Pilling/Bubbling |

Low (especially with proper coating); higher in uncoated or low-twist yarn versions |

|

Country First Produced (with Year) |

United States, 1940s (commercialized post-WWII with synthetic yarn development) |

|

Biggest Exporter Country (Latest Data) |

China (Exported ~1.2 billion meters of Oxford fabric in 2023) |

|

Recommended Washing Temperatures |

Hand or machine wash at 30°C – 40°C; avoid high heat drying |

|

Finishing Uses to Increase Functionality |

Anti-UV finish, Anti-mildew, Flame retardant, Anti-bacterial, Teflon coating, Calendering |

|

Common Applications |

Backpacks, laptop bags, jackets, tents, car covers, patio furniture, rainwear, promotional totes |

|

Abrasion Resistance |

10,000 – 30,000 cycles (Martindale or Wyzenbeek test) |

|

Water Resistance Level |

1000mm to 5000mm Hâ‚‚O (depending on coating thickness) |

|

Color Fastness |

3–4 (Dry) |

|

Tear Strength (Warp/Weft) |

Approx. 20–30 N (depends on coating and yarn density) |

|

UV Resistance |

Medium (Can be enhanced with UV finish) |

|

Print Compatibility |

Compatible with screen printing, sublimation (on white base), transfer printing |

|

Eco-Friendliness |

Standard version: Not biodegradable. Recycled polyester (rPET) versions available |

|

MOQ (Commercial) |

500 – 1000 meters per color/design (varies by supplier) |

Table Of Contents

- Understanding the ‘300D’ in 300D Oxford Fabric

- How Strong Is 300D Oxford Fabric?

- Common Uses of 300D Oxford Fabric

- Properties That Make 300D Oxford Fabric Special

- How 300D Oxford Fabric Compares to Other Denier Grades

- Pros and Cons of 300D Oxford Fabric

- How to Maintain and Care for 300D Oxford Fabric

- Final Thoughts on 300D Oxford Fabric

- FAQs About 300D Oxford Fabric

Understanding the ‘300D’ in 300D Oxford Fabric

Alright, let’s decode “300D.”

Denier (D) measures the thickness of individual threads used to weave the fabric. Specifically:

- 1 denier = 1 gram per 9,000 meters of yarn

- So, 300D means the yarn weighs 300 grams per 9,000 meters.

In short, the higher the denier, the thicker and heavier the thread. A 300D fabric is mid-range in terms of strength and weight—more durable than 210D, but lighter than 600D.

How Strong Is 300D Oxford Fabric?

Think of 300D Oxford like the Swiss Army knife of textiles. It’s strong enough to handle tough environments, but not so heavy that it becomes a burden.

- Tensile strength typically ranges from 150 to 200 lbs/inch, depending on the weave and finish.

- It resists tearing and abrasion fairly well.

- It holds shape better than lighter fabrics like 210D.

In practical use? It works well in everyday gear that faces moderate stress.

Common Uses of 300D Oxford Fabric

This fabric pops up everywhere once you start noticing it. Some common uses include:

- Backpacks and school bags

- Luggage and soft-sided suitcases

- Outdoor jackets and coats

- Tents and camping gear

- Pet carriers

- Laptop bags

- Furniture covers

It’s the go-to material when you need a balance of strength, weight, and price.

Properties That Make 300D Oxford Fabric Special

Let’s break down the reasons manufacturers love this fabric.

Durability and Strength

For a mid-weight fabric, 300D Oxford holds its ground. The woven basket-like pattern adds to its strength. It can take rough use, resist punctures, and won’t rip easily.

Water Resistance and Coating Types

Most 300D Oxford fabrics are coated with PU (polyurethane) or PVC for water resistance. Numbers don’t lie:

- PU coating usually gives a water resistance of 1,000–2,000 mm Hâ‚‚O

- Some can go up to 5,000 mm, making it water-repellent in rain

That means your stuff stays dry even if the weather doesn’t cooperate.

Breathability and Flexibility

Breathability depends on the coating. PU allows more airflow than PVC, but both affect how much the fabric can breathe.

The fabric stays flexible, though. It doesn’t stiffen or crack in cold weather, which is a bonus if you’re using it outdoors.

How 300D Oxford Fabric Compares to Other Denier Grades

Numbers help you choose the right fabric, especially when durability matters.

210D vs 300D Oxford Fabric

- Weight: 300D is heavier

- Strength: 300D wins again

- Use Case: 210D is better for ultra-light products like shoe bags or liners

- Verdict: Choose 300D when durability matters more than minimal weight

300D vs 600D Oxford Fabric

- Weight: 600D is almost twice as heavy

- Durability: 600D handles rough use better (good for heavy-duty backpacks)

- Flexibility: 300D is more flexible and easier to fold

- Price: 300D is generally cheaper

Pros and Cons of 300D Oxford Fabric

Let’s be fair and square—no fabric’s perfect.

Pros of 300D Oxford Fabric

- Lightweight yet durable

- Water-resistant when coated

- Affordable and easy to work with

- Good strength-to-weight ratio

- Flexible and soft to the touch

Cons of 300D Oxford Fabric

- Not as tough as 600D or Cordura

- Needs coating for waterproofing

- Lower UV resistance over time

- Not fully breathable (depending on coating)

How to Maintain and Care for 300D Oxford Fabric

Want it to last? Here’s what you should do:

- Clean with mild soap and cold water—avoid bleach

- Air dry only—no hot dryers

- Store in a cool, dry place to prevent mildew

- Avoid constant sun exposure—UV can degrade the coating

With proper care, 300D Oxford can last 5 to 10 years, depending on usage.

Final Thoughts on 300D Oxford Fabric

300D Oxford fabric walks the line between lightweight performance and daily durability. It’s not invincible, but it punches above its weight in most situations. Whether you're making gear, buying a backpack, or covering outdoor furniture, this fabric checks all the right boxes—affordable, strong, and versatile.

Don’t underestimate its mid-tier status. Sometimes, middle-of-the-road is exactly what you need.

FAQs About 300D Oxford Fabric

1. Is 300D Oxford fabric waterproof?

Not by default, but most versions come coated with PU or PVC to make them water-resistant.

2. Can I use 300D Oxford fabric for outdoor furniture covers?

Yes, it's commonly used for that. Just ensure it's coated for water and UV resistance.

3. What’s the difference between 300D and 600D Oxford?

600D is heavier, stronger, and more suitable for rough use. 300D is lighter and more flexible.

4. How long does 300D Oxford fabric last?

With proper care, it can last 5–10 years, depending on use and exposure.

5. Is 300D Oxford fabric breathable?

It depends on the coating. PU-coated versions allow some breathability; PVC does not.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.