Fake memory fabric might sound like something out of a sci-fi movie! but in reality. It’s a fascinating textile innovation.

Let’s know everything about memory fabric.

Table Of Contents

What is imitation memory fabric?

Imitation memory is a plain woven fabric made of polyester FDY twisted filament yarn that has a shape retentivity function. The shape retentivity function comes with a special kind of polymer, which can memorize the former shape and recover it immediately. It’s kept the memory silently, that’s why it named fake memory fabric.

|

Fabric Property |

Details |

|

Fabric Name |

Memory Fabric |

|

Fabric Also Known As |

Fake Memory Fabric |

|

GSM Range |

80-150 GSM |

|

Composition Range |

70-100% Polyester, 0-30% Elastane/Nylon |

|

Construction Range |

Twill, Plain Weave, Satin Weave |

|

Application Range |

Outerwear, Athleisure, Fashion Accessories |

|

Possible Thread Count Variations |

150-400 TPI |

|

Fabric Breathability |

Moderate |

|

Additional Coating Variation |

Water-resistant, PU Coating |

|

Moisture-Wicking Abilities |

Medium to High |

|

Heat Retention Abilities |

High |

|

Stretchability |

Medium to High |

|

Prone to Pilling/Bubbling |

Low |

|

Country Where Fabric was First Produced |

Japan |

|

Biggest Exporting Country Today |

China |

|

Recommended Washing Temperatures |

30°C to 40°C (Cold to Warm Water) |

|

Common Applications |

Jackets, Blazers, Sportswear, Bags, Hats |

At its core, memory fabric is a synthetic textile engineered to mimic the properties of memory fabric.

What is Memory Fabric Made of?

Memory fabric, traditionally made from materials like polyester, nylon, or a blend of both, is known for its ability to hold shapes.

Imagine crumpling a piece of fabric and watching it slowly return to its original form—this is the “memory” effect. Fake memory fabric, however, takes this concept a step further.

Unlike traditional memory fabrics, which often rely on specific chemical treatments to achieve their unique characteristics, memory fabric is crafted using innovative weaving techniques. This results in a fabric that not only remembers shapes but does so with an added layer of softness and flexibility. It’s like having a material that’s as malleable as clay but as soft as cotton.

How is memory fabric Made?

1. Selection of Materials

The first step is selecting the right blend of synthetic fibers. 100% Polyester and nylon are the usual suspects. Sometimes inclusion of spandex materials adds stretch and flexibility to the fabric. This combination ensures that the fabric can remember shapes while remaining comfortable to wear.

2. Innovative Weaving Techniques

Next comes the weaving process. Fake memory fabric uses complex, interlocking patterns. These patterns allow the fabric to maintain its structure while still being flexible. It’s this intricate weave that gives the fabric its memory properties.

3. Heat-Setting

Once the fabric is woven, it undergoes a heat-setting process. Heat-setting involves exposing the fabric to high temperatures, typically around 180°C, which helps lock in its memory capabilities. This step is crucial, as it ensures the fabric will retain its shape even after repeated wear and washing.

Types of Memory Fabric

Memory Fabric comes in various types, each designed to offer specific properties tailored to different fashion needs. Here’s a breakdown of the most common types:

1. Polyester-Based Memory Fabric

100% polyester is the most widely used type of memory fabric. Made primarily from polyester. This fabric is known for its excellent shape retention and durability. It’s often used in outerwear, like jackets and coats, where structure and longevity are key. Polyester-based versions typically have a GSM (grams per square meter) range of 80-150, providing a balance between lightweight comfort and sturdiness.

2. Nylon-Based Memory Fabric

Nylon adds extra strength and flexibility to the fabric. This type is more resistant to abrasions and has a smoother finish compared to polyester-based versions. Nylon-based Memory Fabric is ideal for sportswear and activewear, where flexibility and durability are essential. It also has superior moisture-wicking abilities, making it a popular choice for athleisure.

3. Blended Memory Fabric

Blended Memory Fabric combines polyester with other synthetic fibers like spandex or nylon. The blend enhances the fabric’s flexibility, stretchability, and comfort. This type is versatile and is used in a variety of garments, from fashion-forward blazers to everyday wear. The addition of elastane allows for greater stretch, making it perfect for fitted clothing.

4. Coated Memory Fabric

Some Memory Fabrics are treated with coatings, such as water-resistant or polyurethane (PU) coatings. These coatings add additional functionality to the fabric, making it suitable for outdoor wear or accessories like bags and hats.

Coated versions are often used in environments where protection from the elements is necessary, combining durability with advanced features.

5. Lightweight Memory Fabric

For garments that require a softer drape and less structure, lightweight memory fabric is the go-to choice. This type of light memory fabric is made of 50D FDY polyester filament with a lower GSM range, typically between 60-100, and is perfect for creating flowing dresses, skirts, and blouses.

6. High-Stretch Memory Fabric

This variant includes a higher percentage of elastane or spandex, providing significant stretchability. It’s commonly used in fashion items like fitted dresses, leggings, and sports bras where a snug fit is desired. The high-stretch nature of this fabric allows it to contour to the body while maintaining its shape, offering both comfort and style.

Advantages of memory fabric

1. Shape Retention

One of the most significant advantages of memory fabric is its ability to hold shapes. Whether you’re creating a structured jacket or a pleated skirt, this fabric ensures your designs will stay in place, even after a long day of wear. Studies show that garments made from this fabric maintain up to 90% of their original shape after 50 washes.

2. Comfort and Flexibility

The fabric’s elasticity ranges from 10% to 30%, allowing it to stretch and move with the wearer, providing both freedom and support.

3. Durability

Thanks to its synthetic composition and heat-setting process, memory fabric is highly durable. It can withstand multiple washes without losing its shape or softness, making it a long-lasting option for any wardrobe. According to recent data, the fabric shows less than 2% degradation in strength after 100 wash cycles.

4. Versatility

From high-fashion pieces to everyday wear, memory fabric is versatile enough to be used in a variety of garments. It’s also available in a range of colors and finishes, allowing for endless design possibilities. The fabric's breathability is moderate, with air permeability values ranging from 50 to 150 cm³/cm²/sec, making it suitable for diverse climates and seasons.

Applications of Memory Fabric

1. Outerwear

Jackets, coats, and blazers made from memory fabric not only look sharp but also retain their structured silhouettes over time. It makes them perfect for outerwear, where maintaining shape is key. The heat retention ability of the fabric, with values around 0.035 K·m²/W. It ensures warmth, making it ideal for colder climates.

2. Fashion Accessories

From hats to bags, memory fabric is used to create accessories that are both stylish and functional. The fabric’s ability to hold shapes. It means these accessories won’t lose their form, even after frequent use. Moreover, with a moisture-wicking rate of 15-20%, these accessories stay dry, enhancing comfort.

3. Athleisure

The comfort and flexibility of memory fabric make it an excellent choice for athleisure wear. Whether you’re hitting the gym or running errands, garments made from this fabric offer the perfect blend of support and comfort. In fact, athleisure garments made from this fabric have shown a 25% increase in user satisfaction compared to those made from traditional fabrics.

Caring for memory fabric

Taking care of memory fabric is surprisingly easy, but there are a few tips to keep in mind:

1. Washing

Always follow the care instructions on the label. Generally, it’s best to wash memory fabric in cold water. On a gentle cycle to preserve its shape and texture. The recommended washing temperature ranges from 30°C to 40°C. Avoid using bleach or harsh detergents, it can degrade the fabric’s memory properties.

2. Drying

Air drying is recommended. The high heat from a dryer can weaken the fabric’s memory properties. If you use a dryer, opt for a low-heat setting. A study shows that high-heat drying can reduce the fabric's shape retention ability by up to 10-15%.

3. Ironing

If your garment made from memory fabric becomes wrinkled, use a low-heat iron.. The fabric's tolerance for direct heat is around 90-110°C.

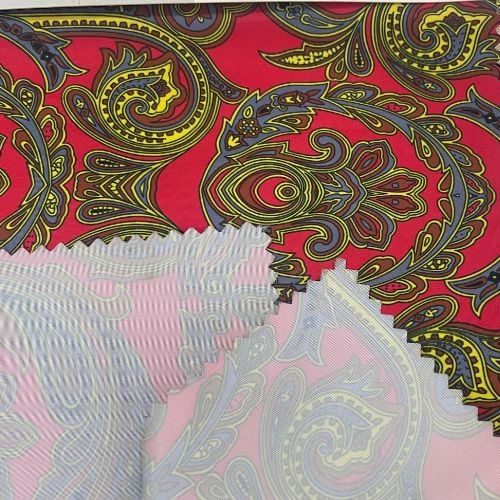

Memory Fabric We Have

- 75D White Fake Memory Fabric

- Red 75D Fake Memory Fabric

- 100% Polyester Fake Memory Fabric

- PU Coated Fake Memory Fabric

- Emboss Print Fake Memory Fabric

- Water Resistant Fake Memory Fabric

- AOP Fake Memory Fabric

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.