Spandex is one of the most popular artificial fabrics in the textile industry. It is a kind of synthetic fabric that has excellent elasticity features. Due to its exclusive elasticity feature, this fabric is widely used in stretchable apparel. Do you know what Spandex fabric is and how it is made?

Table Of Contents

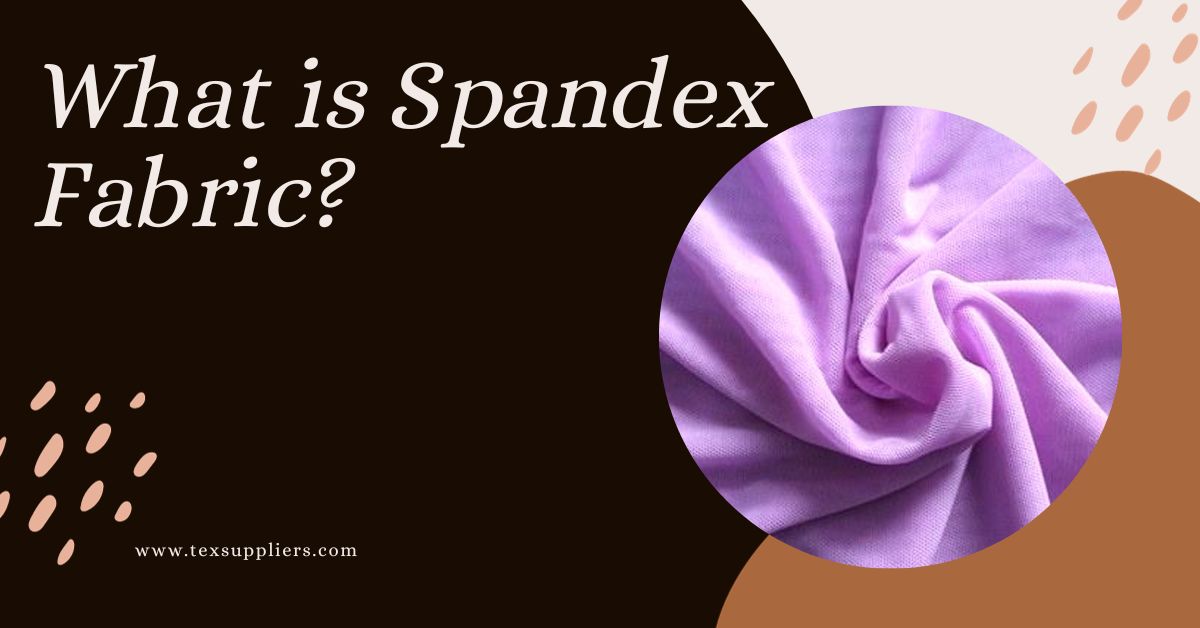

What is Spandex fabric?

Spandex fabric is a kind of lightweight, artificial fabric that is well-known for its exceptional flexibility. In Europe, as well as many other areas of the globe, it is referred to as 'elastane.' It is a general term that refers to a copolymer of polyether-polyurea textiles that have been produced via a variety of techniques. In certain regions, this substance is referred to as elastane.

Most of the time spandex has been mixed with other fiber such as Polyester Spandex, Nylon Spandex. Widely used to produce 2-way stretch and 4-way stretch fabric including mechanical stretch fabric.

Spandex is constructed of a synthetic polymer known as polyurethane, which has a remarkable capacity to stretch. Spandex has the ability to quickly stretch up to seven times its original size, making it a popular option among athletes and textile manufacturers that develop form-fitting garments. Garments composed of spandex are very comfortable and well-fitting.

Spandex Fabric Properties

|

Fabric Name |

Spandex Fabric |

|

Fabric Materials |

Copolymer of Polyether-polyurea |

|

Fabric Stretchability |

Excellent |

|

Fabric Breathability |

High |

|

Heat retention Capabilities |

Low |

|

Moisture-wicking Capabilities |

Excellent |

|

Prone to Bubbling |

High |

|

Washing Temperature |

Cold or Warm |

|

Applications |

Stretch pants, Underwear, Yoga pant, Bra, Skinny pants, etc |

Types of Spandex Fabric

There are 3 different types of spandex fabric available in the textile industry; Spandex, Elastane, and Lycra. Both of these three types of spandexes have several dedicated features that are different from each other. Now, let's take a look at these 3 types of spandex fabric.

Spandex is an anagram of the word "expands." Although the name "spandex" was never meant to be the dominant term for elastane fabric, it stayed in the public's consciousness. Most Americans, as well as Canadians today, refer to it accordingly.

The name "elastane" is used by the majority of Europeans to describe this sort of cloth. The most chemically accurate way to refer to this cloth is as elastane.

The DuPont Corporation has a registered trademark for Lycra. Only DuPont's Spandex may be termed Lycra. This fabric is chemically equivalent to spandex or elastane textiles, and it has the same properties.

Spandex vs. Elastane

Although the words elastane and Spandex both relate to the same material, they are distinct in that Spandex is indeed the brand name for elastane. The main distinction between elastane as well as Spandex is that elastane is a kind of synthetic fabric, whereas Spandex is a brand name for elastane. Furthermore, the word elastane is used chiefly in Europe, while the phrase spandex is used mainly in America.

What is Spandex made of?

We already clarified that Spandex is an artificial or synthetic fabric. Now it is the question, what is Spandex made of? Spandex fabric is generally manufactured from polyurethane synthetic polymer. With its incredible stretchability, this polymer is a game-changer. Additionally, it is responsible for the peculiar elastic feature of Spandex.

Dry spinning, wet spinning, reaction spinning, and melt extrusion are some of the ways that may be used to make it. However, in the modern environment, the dry spinning process is the most preferred way of creating this material. In fact, this effective process is used to make about 90% of all spandex fabrics in the world.

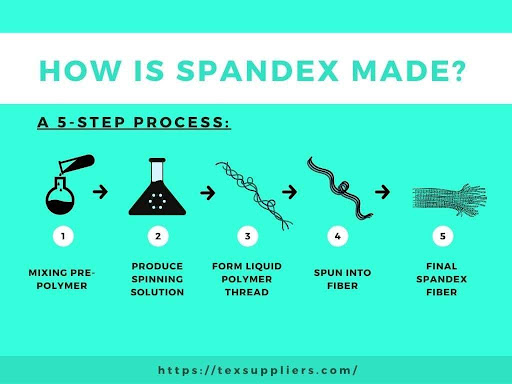

How is Spandex made?

The manufacturing process of Spandex fabric is involved 5 different steps. Here in this section, we are going to discuss the manufacturing process of Spandex.

Step 01: Mixing Pre-Polymer

First of all, a macro glycol and a di-isocyanate monomer are mixed to make a pre-polymer. They're combined in a reaction chamber and require ideal conditions to react as well as generate a pre-polymer. The ratio of composite material is essential for the fibers' various qualities.

Step 02: Produce Spinning Solution

The pre-polymer is combined with an equivalent quantity of di-amine inside the chain extension process. To make the spinning solution, it produces a solution that is dissolved with a solvent. The solvent thins the solution, making it easier to handle. The fiber manufacturing cell may then be injected with it.

Step 03: Form Liquid Polymer Thread

The polymer is pushed through a spinneret, a metallic plate with microscopic holes in it, in the fiber manufacturing cell. The solution forms liquid polymer threads. The heated strands move through the cell with nitrogen as well as solvent gas. The liquid polymer chemically reacts and solidifies.

Step 04: Spun into Fiber

Solid fibers are propelled out of the cylinder spinning cell after they have been spun into fibers. When they are subjected to pressured air, they twist together to produce twisted strands of material. This pressurized air may be used to create strands of varying diameters and shapes.

Step 05: Submerged Final Spandex Fiber

Finally, the spandex fiber is submerged in a finishing agent, which is typically composed of either magnesium stearate or even a chemically related compound. Once it has been wound onto a spindle, it is prepared to be woven as fabric with other fibers.

What is Spandex used for?

Spandex is a synthetic fabric that has excellent stretchable features. This sort of fabric is becoming more popular, and it can now be found in hundreds of various clothing. Spandex is well recognized as a fabric that is widely utilized in the garment industry. However, it is also a helpful fabric for firms in the hospitality and industrial sectors.

Spandex textiles are often utilized in clothing that needs both comfort and fit. Many goods in the sports clothing and accessories business are made using Spandex. Just like Spandex is beneficial for the garment sector, it is also helpful for industrial uses. It's also utilized to make things like fitted sheets as well as microbead pillows for the home.

Applications of Spandex

- For form-Fitting Garments: Used in form-fitting garments for men and women, cotton and wool socks.

- For Sportswear: Used in swimwear, and bicycling apparel.

- For Motion Capture Suit

Final Thoughts

Spandex fabric is one of the best ways to go in terms of Stretchable apparel. It is a man-made fabric that has good elasticity functionality. Since it has excellent durability and breathability, this fabric is widely used in the textile industry.

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.