240T Pongee fabric is a lightweight, durable material. It is widely known for its smooth texture and versatile applications in umbrellas, apparel, and more. Learn more about its uses, properties, and advantages.

Table Of Contents

What is 240T Pongee Fabric?

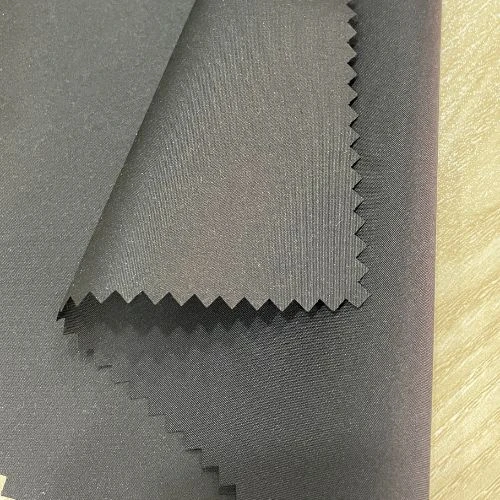

240T Pongee fabric is made of mostly 75D DTY fine filament yarn. It is known for its medium density, lightweight structure, and high durability. The "240T" indicates a thread density of 240 threads per square inch. It offers an ideal balance between breathability and resilience.

Pongee fabric was traditionally made from silk. But today’s 240T pongee is usually crafted from polyester or poly/spandex blends. It provides an affordable, long-lasting alternative with a soft, smooth finish.

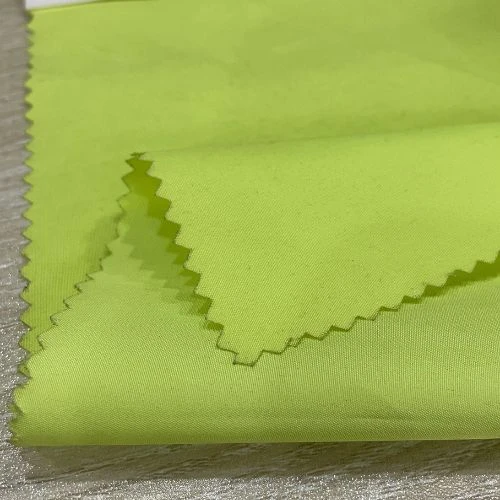

Figure: 210T Polyester Pongee Fabric

Types of 240T Pongee Fabric Based on Coating and Material

1. Types of 240T Pongee Fabric Based on Coating

Different coatings can significantly enhance the functionality of 240T pongee fabric, making it versatile for specific applications. Here are some common coating types:

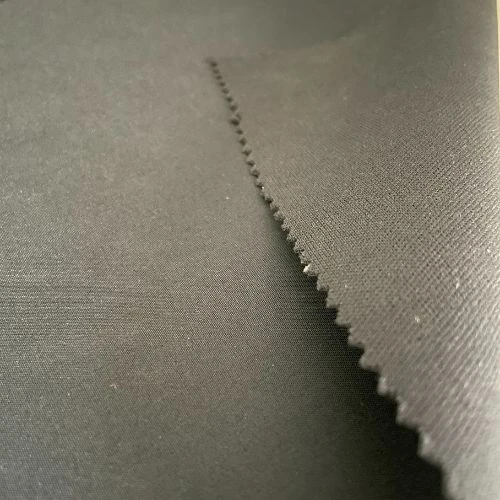

i. PU-Coated 240T Pongee

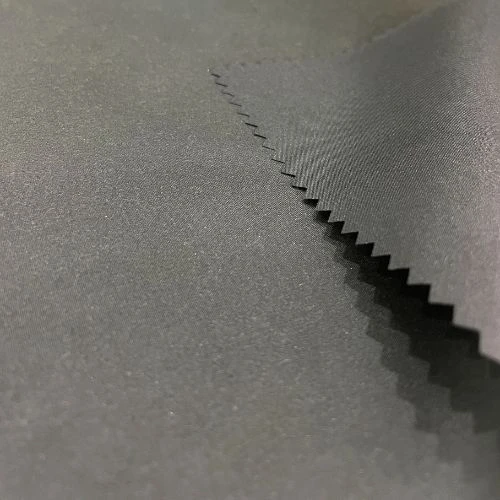

Figure: 240T Pongee Fabric with PU Coating

Polyurethane (PU) coating adds a thin protective layer to the fabric. It enhances water resistance and durability. PU-coated pongee is popular for outdoor items like umbrellas, raincoats, and tents. This coating keeps the fabric lightweight while providing a waterproof finish.

ii. PVC-Coated 240T Pongee

Polyvinyl chloride (PVC) coating gives a more rigid, weather-resistant finish. PVC-coated pongee is ideal for applications requiring robust protection, such as outdoor banners, heavy-duty umbrellas, and luggage. This coating is thicker than PU and provides a glossy, durable exterior.

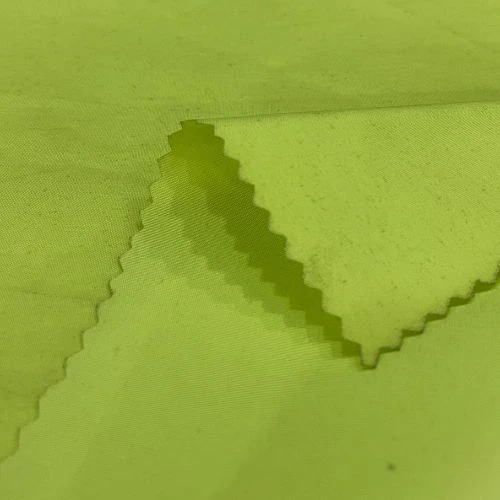

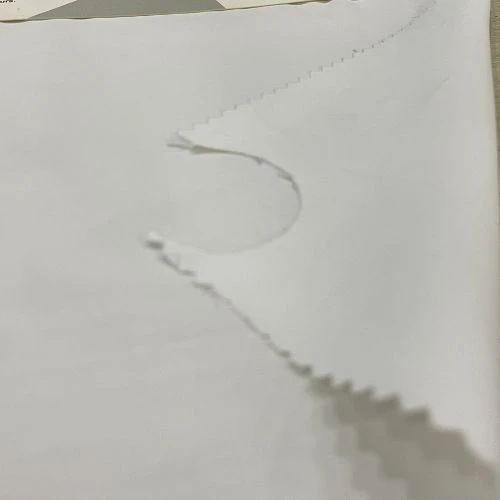

iii. AC-Coated 240T Pongee

An acrylic (AC) coating enhances the fabric's resistance to sunlight and fading, making it an excellent choice for outdoor uses. AC-coated pongee is often used in flags, banners, and other items exposed to sunlight for extended periods, as it maintains color vibrancy and reduces wear from UV rays.

Figure: 240T Pongee with WR and AC Finishing

iv. Water-Repellent (W/R) Coating

Water-repellent (W/R) coatings improve pongee's ability to resist moisture without compromising its breathability. This type of pongee fabric is often used in lightweight jackets, umbrellas, and windbreakers, as it keeps users dry while allowing airflow for comfort.

v. Silver or Black Coating (UV-Protective)

A silver or black coating provides UV protection, which makes it ideal for products exposed to the sun, such as parasols and high-quality umbrellas. This coating reflects sunlight and helps prevent fabric degradation, while also providing shade and UV protection for users.

2. Types of 240T Pongee Fabric Based on Material

240T pongee fabric also varies depending on the primary material used. The choice of material affects the fabric’s texture, durability, and applications. Here’s a breakdown:

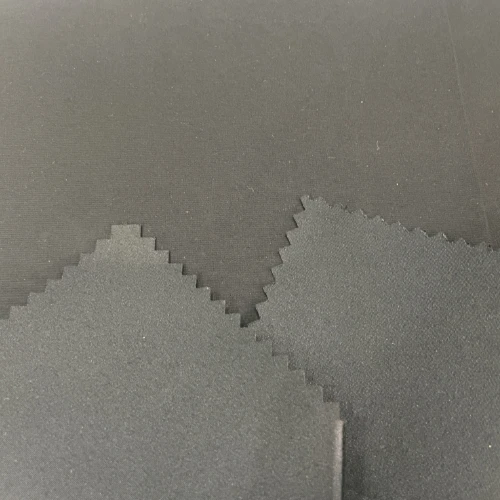

i. 100% Polyester Pongee

Figure: 100% Polyester 210T Pongee

Polyester pongee is the most widely used version due to its cost-effectiveness, durability, and lightweight feel. Polyester’s inherent resistance to wrinkles, shrinking, and stretching makes it ideal for everyday items like umbrellas, lining fabrics, and apparel. This fabric is also easy to dye, providing vibrant colors that are fade-resistant.

ii. Poly/Spandex Blended Pongee

A polyester and spandex blend introduces slight elasticity to the fabric, which increases flexibility and comfort. This type is often used in garments that require a little stretch, such as outerwear linings and sportswear. The spandex content, typically low, provides a gentle stretch while maintaining the smooth, structured look of pongee.

iii. Silk Pongee

Though less common, silk pongee offers a luxurious feel and natural sheen. Historically, pongee was made from silk, and it is still produced in small quantities for high-end applications. Silk pongee is often found in designer apparel, scarves, and elegant linings due to its softness, breathability, and beautiful drape.

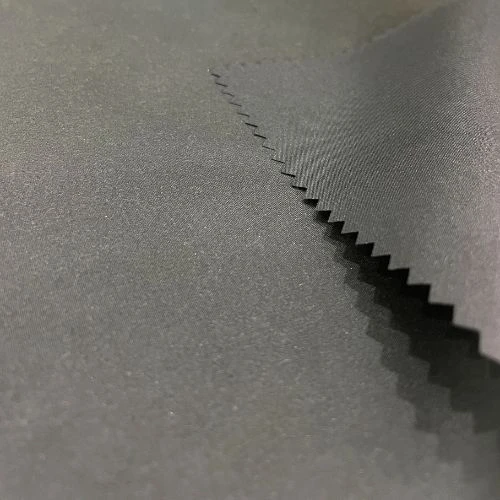

Properties of 240T Pongee Fabric

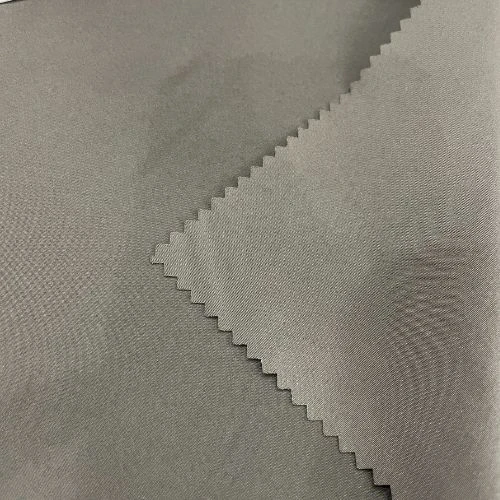

Figure: 75Dx75D 210T Polyester Pongee Fabric

240T Pongee fabric is known for its balance of lightweight feel and strength. It makes it suitable for a range of everyday applications. Here’s a quick breakdown of its key properties:

- Composition: 100% polyester or poly/spandex blends

- GSM (Grams per Square Meter): Approximately 50-70 GSM, ensuring lightweight durability

- Weave: Plain weave with a soft, silky texture and a slight slubbed effect

- Finish: Often water-resistant or UV-protective coatings are added for outdoor use

These characteristics make 240T pongee a practical choice for many applications, from outdoor gear to lightweight apparel.

Applications of 240T Pongee Fabric

Due to its versatile properties, 240T Pongee fabric has a variety of uses across different industries. Here are some of the most common:

1. Umbrellas

The water-resistant nature of 240T pongee fabric makes it ideal for umbrellas. It provides a strong yet lightweight canopy, which can effectively repel water while also protecting against UV rays when coated with a UV-protective layer.

2. Outerwear and Apparel Linings

240T pongee is often used as a lining fabric for jackets, coats, and other outerwear. Its smooth surface and ability to resist wrinkles make it an excellent choice for adding structure to clothing without adding bulk.

3. Bags and Luggage Linings

The strength and durability of 240T pongee fabric make it suitable for use as lining in bags, luggage, and backpacks. Its abrasion resistance ensures that it withstands regular wear and tear while maintaining a sleek appearance.

4. Tents and Outdoor Gear

Because of its lightweight and weather-resistant qualities, 240T pongee fabric is commonly used in tents, camping gear, and other outdoor applications. Its flexibility and resilience allow it to withstand various environmental conditions.

Benefits of Using 240T Pongee Fabric

240T Pongee fabric offers several benefits that make it a popular choice for manufacturers and consumers alike:

- Lightweight and Durable: Despite its low weight, 240T pongee has a strong weave. Makes it durable for both indoor and outdoor applications.

- Weather-Resistant: With a PU or water-resistant coating, this fabric can effectively repel water, making it perfect for rain gear and umbrellas.

- Wrinkle-Resistant: Its smooth texture and resilience make it resistant to wrinkles, which enhances its appearance in various applications.

- Cost-Effective: Compared to silk or other natural fabrics, 240T pongee provides an affordable alternative without compromising on aesthetics or functionality.

- Eco-Friendly Option: Pongee fabric, especially when made from polyester, can be produced sustainably, and it’s often chosen as a vegan-friendly alternative to silk.

How is 240T Pongee Fabric Made?

The production process of 240T Pongee fabric typically involves the following steps:

- Weaving: Polyester or poly/spandex fibers are woven in a plain weave pattern. It has balanced warp and irregular filling yarns ensuring a smooth, soft texture.

- Dyeing and Finishing: The fabric is then dyed and treated with finishes such as water-resistant or UV-protective coatings.

- Quality Check: Each batch is inspected for consistency in thread density, texture, and color quality.

These steps ensure that the fabric meets the industry standards for durability and appearance.

Conclusion

240T Pongee fabric has become an essential material in the textile industry due to its lightweight yet durable nature, weather-resistant capabilities, and versatility in applications. From umbrellas to outdoor gear, this fabric offers an affordable solution that balances function and style.

FAQs

1. What is the difference between 210T and 240T pongee fabric?

The primary difference is the thread density. 240T has a higher density, making it slightly more durable and resilient compared to 210T.

2. Is 240T pongee fabric suitable for outdoor use?

Yes, especially with a water-resistant or UV-protective coating. It’s often used in umbrellas, tents, and other outdoor products.

3. Can 240T pongee fabric be washed in a machine?

It depends on the specific finish, but generally, polyester-based pongee can be machine-washed at 30°C.

4. Is 240T pongee fabric eco-friendly?

When made from polyester, it is a more sustainable choice compared to natural silk. It’s also a vegan-friendly fabric option.

5. What is the GSM of 240T pongee fabric?

The GSM of 240T pongee fabric typically ranges between 50-70, providing a lightweight yet durable structure suitable for multiple applications.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.