While picking the materials like fabric, people consider the type of fabric, woven or knit? Though the difference is slight, when it comes to finished garments, the difference becomes significant. A set of factors like pattern, flexibility, durability, washability, and application come into play. That’s why it’s worth knowing the difference between the woven and knit fabric.

Before we jump into the discussion on woven vs knit, we have to know what woven and knit fabrics are.

Table Of Contents

Woven fabric:

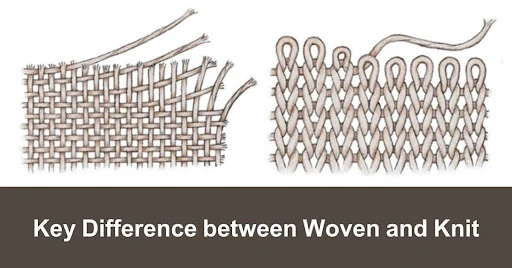

Fabrics made by the weaving process are called woven fabrics. In the weaving process, two sets of yarns interlace and cross each other at right angles. Lengthwise yarns are known as warp and widthwise are called weft.

Knit fabric:

Knit fabrics, on the other hand, are made by the knitting process. It includes forming loops from a set of yarn. Because a knit fabric is made of interloping, it has no edge.

Basic Difference between woven and knit

Construction:

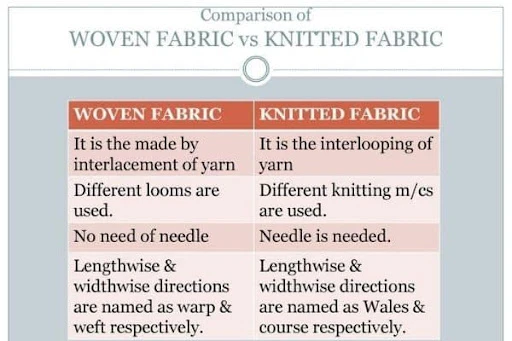

The main difference between woven and knit fabric is how they are constructed. While the woven fabric is produced on a loom by the interlacement of warp and weft yarn, knit fabric is made by the interloping of yarn by means of the needle.

Yarn used:

One of the basic differences lies in the yarn that composes of woven and knit fabric. Woven fabric is made with two sets of yarns namely warp and weft. On the other hand, a knit fabric is produced by employing only a yarn forming loop by itself.

Stretch:

The best and easiest way to distinguish the woven fabric from the knit one is stretching. There is a big difference in the amount of stretch both give. When pulled along the width, a knit fabric tends to stretch a lot and a little along the length. But woven fabric on the contrary gives no stretch when pulled along its width and a slight stretch along the length.

Fabric salvedge:

Anyone can identify whether it’s knit or woven fabric if looking at the salvedge. Usually, woven fabric has salvedge whereas knit has no salvedge. Since the knit fabric has no salvedge and is made with a single yarn, it tends to be unrove when you open a loop.

Wrinkle:

Another way to differentiate woven fabric from knit one is the wrinkle test. All you have to do to do the test is a ball a small amount of fabric up into your fist for a moment. If the fabric returns to its original shape with little effect, it’s nothing but a knit fabric. If, on the other hand, you find creases in the fabric, it’s likely to be a woven fabric.

Curling tendency:

Last but not least, if you are still unable to differentiate the fabric, check if the fabric has curling or deforming problems. Knit fabric curls at the edge because of the way how it’s constructed. It’s the common nature of knit fabric; maybe you have seen your t-shirt will curl at the bottom.

However, unlike knit fabric, woven fabric has no curling problem because of its weaving construction. Moreover, woven fabric has selvage, preventing the curling tendency.

Now, all that you know is how to identify woven and knit fabrics. Once you know what the basic difference between woven and knit is, it’s time to decide which one you need.

Wrap it Up

Basic Difference Between Woven and Knit Fabric

|

SL No |

Woven Fabric |

Knit Fabric |

|

01 |

Two Set of Yarn are used |

Only one set of yarn is used. |

|

02 |

Sizing is important before weaving |

Sizing is not much important |

|

03 |

Less production capacity |

More production capacity |

|

04 |

Production cost is higher than knitting |

Less Production Cost |

|

05 |

Done by shade formation |

Done by loop formation |

|

06 |

Yarn preparation is essential |

Yarn Preparation is not necessary |

You may know details about

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.