Table Of Contents

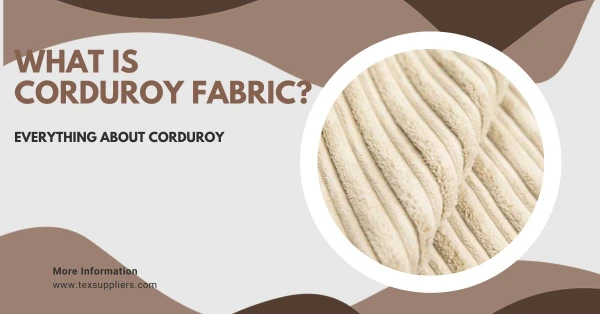

What is Corduroy Fabric?

Corduroy is a kind of twill weave fabric featuring broad vertical ribs, which implies the threads are knitted with each other in diagonal stripes. It is a durable fabric that is made of different types of materials.

Most of the Corduroy fabric in the textile industry is made of cotton or a blend of cotton. The fabric's ridges are perhaps one of the distinctive features. There are a lot of applications that are manufactured with this fabric. However, Pants, jackets, shirts, skirts, and suits are the most common applications of Corduroy fabric.

Types of Corduroy Fabric

Corduroy fabric is available in different subtypes. Each and every type of Corduroy comes with various exclusive features. Let's take a look at the different kinds of corduroy fabric.

1. Standard corduroy:

Standard Corduroy is one of the most popular Corduroy fabrics. This kind of Corduroy features 11 Wales count per inch. A Corduroy with 8 to 13 Wales is also considered Standard Corduroy.

2. Pinwale corduroy:

Pinwale corduroy is another popular type of corduroy. Every square inch of this type of Corduroy contains many micro ridges. Approximately 21 Wales in every inch may be found in some of the best pinwale corduroys.

3. Pigment-dyed Corduroy:

The majority of corduroy textiles are pigment-dyed Corduroy. This type of corduroy dyeing process produces a speckled pattern that gets more pronounced with each wash.

4. Bedford Corduroy:

Bedford cord is indeed an American cloth with a corduroy-like texture. The cords are oriented vertically in this heavy-weight, warp-faced, corduroy fabric. Bedford cord is commonly used in bottom-weight clothes and is manufactured from cotton yarns.

5. Elephant Corduroy:

This Corduroy features exceptionally broad, thick cords and is named after the unique wrinkles in an elephant's skin. This type of Corduroy gets its name from the wide velvet ribs that keep the cloth warm. The wale number of elephant cord cloth can range from 1.5 to 6.

Corduroy History

Corduroy has gone through a number of transformations during the previous half-century. Corduroy is a descendant of the Egyptian fustian cloth produced around 200 AD. In the eighteenth century, English textile producers invented contemporary Corduroy. Most of us have fond memories of the fabric, remembering it as a fashionable fall staple, while others recall the 1970s corduroy outfits.

However, Corduroy has a long and illustrious history. What began as a regal cloth has evolved into one of today's popular fabrics? And while it may appear to be a twentieth fashion trend, it actually has a two-thousand-year background. Corduroy fabric has been in and out of fashion many times.

Properties

|

Fabric Name |

Corduroy fabric |

|

Manufacturing Materials |

Cotton, Cotton Blend, Wool, Polyester |

|

Fabric Durability |

High |

|

Fabric Breathability |

Medium |

|

Heat retention Capabilities |

Variable |

|

Fabric Stretchability |

Low |

|

Moisture-wicking Capabilities |

Medium |

|

Prone to bubbling |

Variable |

|

Applications |

Pants, Jackets, Shirts, Uniforms, Skirts, Pillows, Upholstery and Suits |

Properties of Corduroy Fabric

What is Corduroy made of?

So, now it is the question, what is Corduroy made of? The manufacturer made this fabric using different types of materials. Most of the Corduroy fabric is made of cotton or a blend of cotton. Since cotton is a durable fiber, this fabric has a durable finish.

Corduroy is typically composed of cotton, although it can also be constructed of polyester as well as cotton mixes or even 100% polyester. Wool is occasionally used in the production of Corduroy. The wrinkles on wool corduroy fabric are not as noticeable as those on corduroy made of other fabrics.

How is Corduroy fabric made?

The manufacturing process of Corduroy fabric is straightforward. Its manufacturing process involves 4 Steps. Let's take a look at the step-by-step manufacturing process of this fabric.

01: Weaving

The 1st step of the Corduroy manufacturing process is weaving. While most of this fabric features plain weaves, it is also possible to manufacture this fabric with twill weaves. Plane waves are made up of weft threads that rotate up and down the warp thread. After completing the weaving process, manufacturers add pile thread with the weaves.

02: Glueing

The next step involves Glueing. The manufacturer applies glue to the woven fabrics back. This method prevents the pile of yarn from pulling through the cutting operation. This material is removed later in the manufacturing process by textile manufacturers.

03: Pile Yarn Cutting

After completing the gluing process, the next step is cutting pile yarn. The manufacturers cut the pile of yarn using an industrial cutter machine. After that, the fiber is combed and singed to create silky, consistent ridges.

04: Dyeing

Textile makers can pigment-dye finished corduroy to create a distinctive, uneven pattern. As the fabric is washed, the design created by the dyeing procedure becomes more prominent. Among the most aesthetically attractive aspects of corduroy is provided by this phase.

Applications of Corduroy Fabric

Applications of Corduroy Fabric

Corduroy fabric is used to produce both apparel as well as furniture products. The manufacturer uses this fabric to manufacture everything from upholstery to workwear. However, this fabric is used to manufacture different apparel like Pants, Jackets, Shirts, Uniforms, Skirts, Pillows, Upholstery, and Suits. Corduroy is frequently used by furniture and accessory manufacturers to construct chair and couch covers and ornamental cushions.

https://youtu.be/V3nkOsWVGYs

Everything You Need to Know about Corduroy

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.