Thinking about knowing more about eco-friendly Melange Fabric and its composition? Then you are on the right track. Go through the entire article to get more information on Mélange fabric, its properties with features, the application, and the challenges that we face while using the fabric.

Table Of Contents

- What is Melange Fabric?

- What is Melange Fabric made of?

- Manufacturing Process:

- Classification of Melange Fabric

- How Can Get Grey Mélange Fabric?

- Properties of Mélange Fabric

- Characteristics

- Fashionable Appearance

- Application

- Challenges that We Face in Making Mélange Fabric

- Why is Mélange Fabric So Popular in the Market?

- Final Thoughts

What is Melange Fabric?

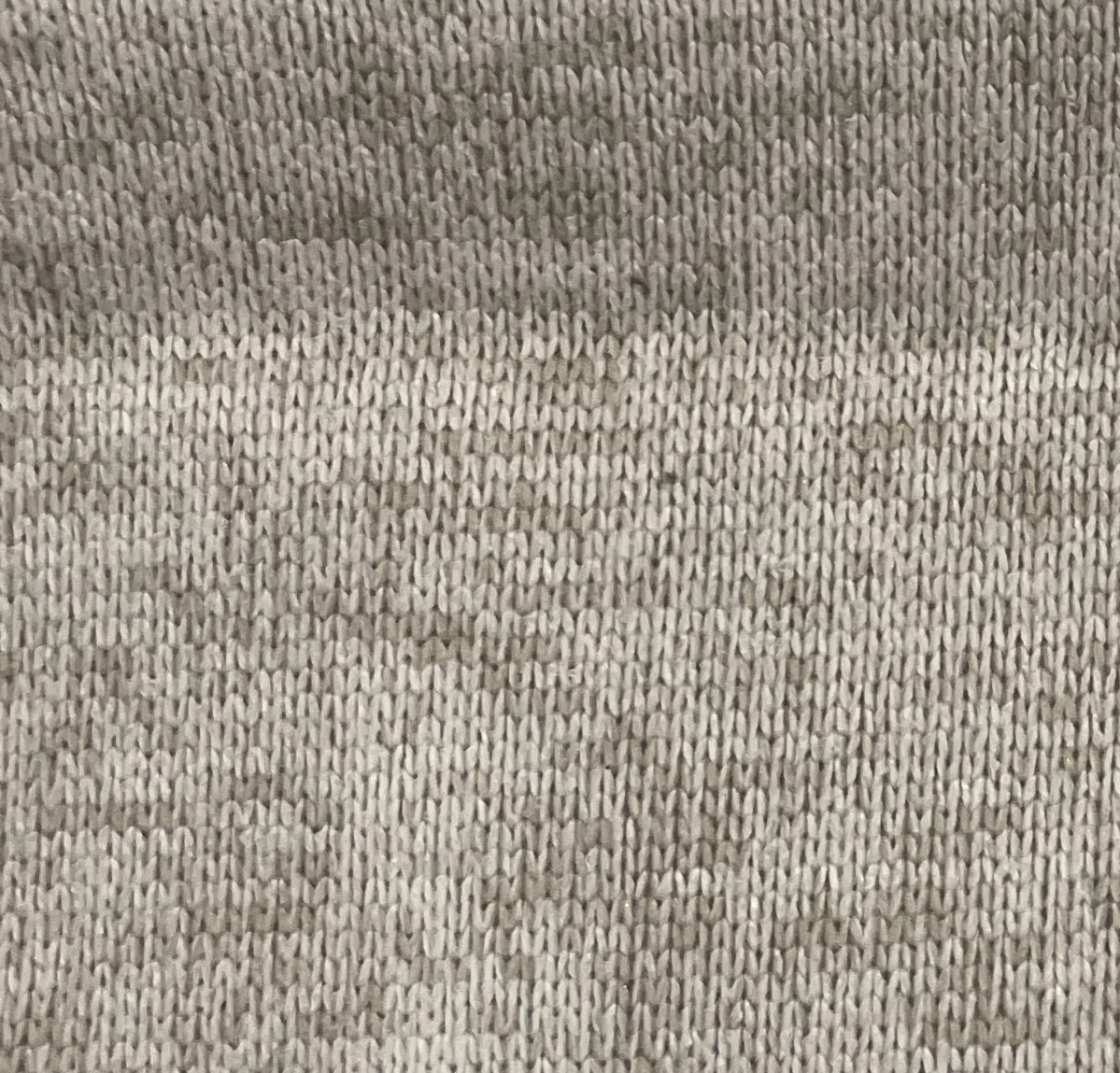

Melange Fabric is produced by weaving or knitting raw fiber or yarn (undyed) and dyed fiber or yarn together to create a melange effect. It is nothing but a mixture of most of the fresh white yarn and a few of the dyed colored yarns. It's also known as cationic fabric. Melange fabric is widely used in sportswear and activewear.

What is Melange Fabric made of?

The raw and dyed fibers used to create mélange fabric can be in cotton, polyester, or any other materials and blended of them. But if the fabric is made of 100% cotton, there should be two different colors of cotton fiber. Several mixed shades can be created by using the many percentages of cotton material. In that case, the method will be known as “Cotton mélange Fabric.” Cotton Mélange fabric comes in different colors with plenty of shades starting from Black to yellow to Red to Pink. In polyester melange fabric, polyester DTY and FDY yarns are used. Sometimes polyester spun and viscose spun yarns are also used to produce knitted melange fabric.

Manufacturing Process:

Melange effects can be achieved by applying techniques below

By using different colored fibers: For example, a grey melange pattern can be created by using a mixture of black and white fiber.

By using different types of fibers: In this case, different types of fibers are used to make the yarn first then each type is individually dyed in yarn form. In terms of polyester/cotton blended fabric, usually, the polyester part is dyed first then the cotton part, resulting in a melange effect.

By using different colors of yarns: The melange pattern can also be achieved by employing different colors of yarns during the fabric texturizing.

Classification of Melange Fabric

Classification based on the type of melange effects:

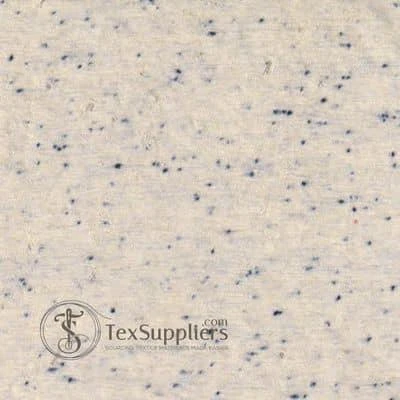

Melange fabric comes in several forms, for instance, Heather, Marl, Siro, and Neppy. Among the mentioned forms, Neppy is the significant one. In Neppy Mélange fabric, there is the utilization of a handful of neps to achieve uniqueness. To get the exact shape in the final product, the size and color play an important role while making the Neppy mélange fabric.

Classification based on the Composition

The composition here means, the blend of cotton, viscose, polyester, and other materials. So, the types are following:

- Cotton (100%)

- Poly-Cotton

- Poly-Viscose

- Polyester (100%)

- Marl

- Tri-Blend

- Core Spun

- Slub

Based on the Core Types, Mélange Fabric can be classified as:

1. Blended Melange Fabric

Here, different fibers are mixed at the perfect ratio whey they get mixed or blended. For Instance: The 50:50 Ratio of Polyester-Cotton Blend or the 60:40 ratio of Cotton-Viscose Blend.

2. Non-Blended Mélange Fabric

Here, no different fibers are blended in a certain ratio. The only that is matter is the well-ranged colors of the same cotton/polyester fiber type.

How Can Get Grey Mélange Fabric?

To get the type of fabric in mixed cotton and viscose fibers, the percentage mostly depends on the buyer’s requirement. For instance: the 90:10 ratio (Cotton+Viscose), and the 85:15 ratio of (Cotton+Viscose) to get the exact shape and color of Grey Melange Fabric.

Properties of Mélange Fabric

|

Fabric Name |

Mélange |

|

Manufacturing Materials |

Cotton, Viscose, Polyester |

|

Fabric Breathability |

Yes, for Outdoor Clothing |

|

Heat Absorption Capability |

Absorbs Heat |

|

Moisture-Resistance capability |

Yes, Absorbs Moisture |

|

Prone to Wrinkle |

Wrinkle-resistant |

|

Fabric Durability |

Durable |

|

Fabric Stretchability |

Stretchable |

|

Hypo-Allergenic Features |

Anti-Allergic |

|

Weather |

Appropriate for Summer |

|

Water-Resistance Ability |

Yes, Waterproof |

|

Washing Temperatures |

Room temperature for at most one hour |

|

Fabric Smoothness |

Better |

|

Applications |

Knitwear, Bed sheets, Denim, Swimwear |

Properties

Characteristics

Mélange Fabric has some exclusive features that mostly revolve around its appearance and environment-friendly nature. Let us look at the features of this Fabric:

Eco-Friendly

Mélange Fabric is a fabric-dyed product of mixed raw fibers. Before dying, the processing can save up to 50% of water in comparison to the traditional process of spinning. This fabric both saves water and energy emissions. Also, the fabric reduces 50% of the water that goes wasted.

Fashionable Appearance

In the textile industry, Mélange fabric is so popular because of its attractive glaze and unique fabric pattern. The use of different effects blended properly and create a wide range of color tones to offer it an enriched look.

Better Fabric Smoothness

Mélange Fabric provides a better look of a smooth fabric that has a softie feel and a polished look. The easy-Blending process is also one of the advantages that you might look for.

Distinctive Dyeing Process

In the process of making Mélange fabric, the special dyeing process has been marked as the best utilization of high technology. The technology perfectly matches the fiber dyes with the color and the mixed textile fibers.

Application

The widely- accepted feature of Mélange Fabric is nothing but the application. The fabric has the most uses in the warp and the weft knitting pieces of machinery. Although it is a bit expensive in cost, the use of mélange fabric is increasing in the clothing industry day by day. Because of the comfort and amazing appearance, the fabric is suitable for knit-fashion wear, especially in sportswear and activewear. Melange used in:

- Hoodie

- Trouser

- T-Shirt

- Pant

- Nightwear

- Under Garments and so on.

Challenges that We Face in Making Mélange Fabric

There are a few limitations or challenges that we may find during the manufacturing process of mélange fabric. These are:

- Variation of Shade: There may not be the proper mixture of fibers and silver doubling. As a result, shade variation might cost you a bit in the fabric.

- Fabric Spots: The quality might be different. We cannot correctly predict the quality of the finished product. But we must keep in mind the white Neps on the dark shades of fibers.

- Ratio Variation: Blending is a must thing in the Mélange Fabric. We cannot just avoid the risk of the im-proportionate ratio of the fibers, although these all depend on the fiber property.

Why is Mélange Fabric So Popular in the Market?

The attractive and uncommon appearance of the Mélange fabric makes it well-accepted in the marketplace. The waviness effect blends properly creating inclusive color tones, resulting in an enriched look. Sometimes, Mélange fabric is also called “Grey mélange Yarn” because of the use of combined two or more fibers. Behind its popularity, there is a structured format that is perfectly different from conventional fabrics. Also, the variety and the texture make the mélange fabric more “I want this.”

Final Thoughts

In simple words, A fabric that needs more than one color of any specific type to make is called Mélange Fabric. Here, the type of fibers can be different too. The individually dyed fabric is dipped into a few dye baths so that it can absorb dyes. It is the fabric of modern textile pieces of machinery to blend fiber in a better way. Although the cost is a bit high, the raw elements and the easy blending process make the Mélange fabric more environmentally friendly with the saving of energy that exceeds the disadvantages.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.