Table Of Contents

What is Plisse Fabric?

To answer what is plisse fabric, it is explicit, Plisse is originally entitled to fabric that is already woven or aggregated into pleats and it is known as a crook or crinkle crepe. The fabric is entitled to any delicate, thin, flexible materialistic stuff made from yarn and directly comes from fibers; this statement will clarify things exquisitely.

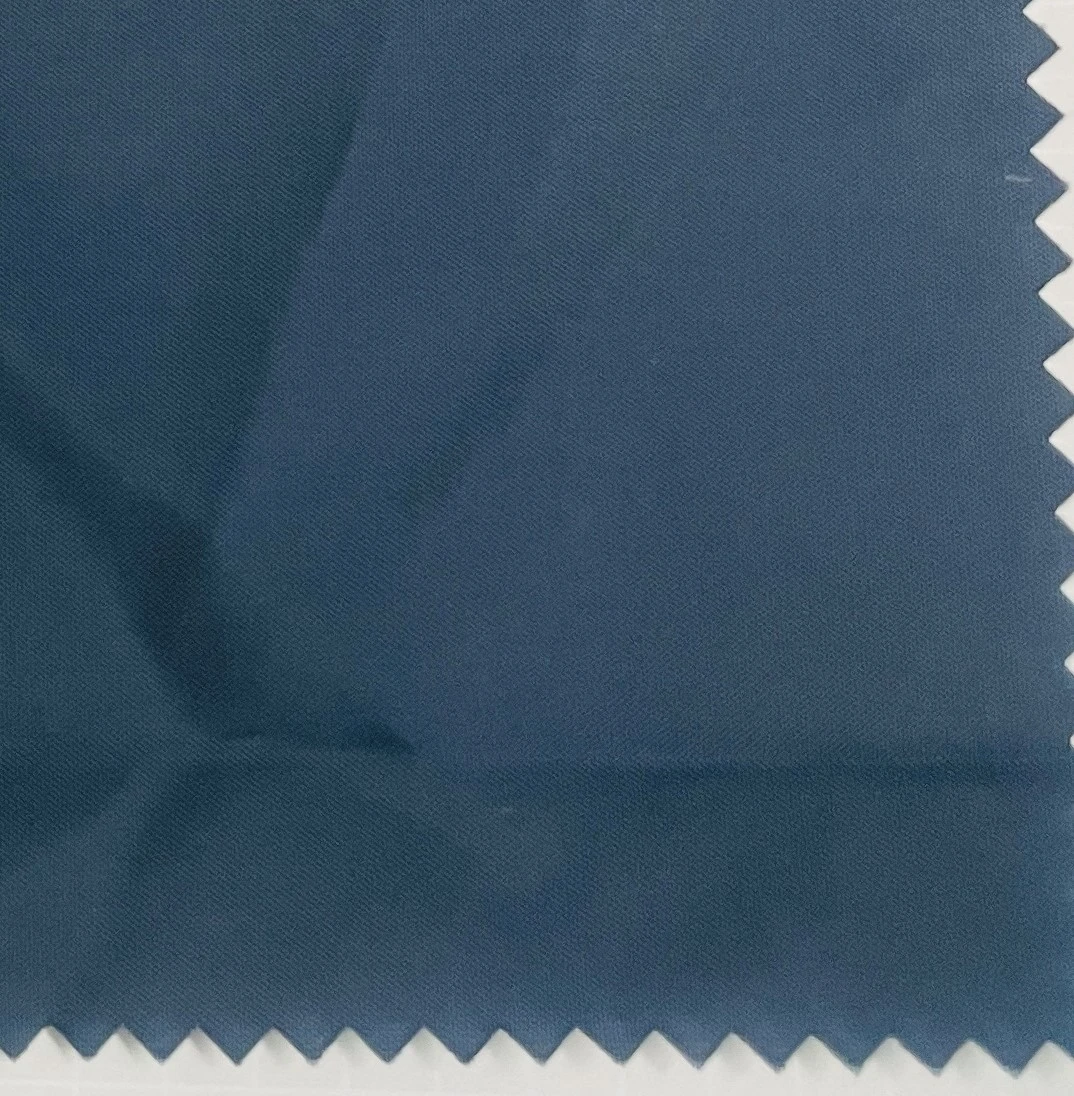

'Plisse' is an exquisite, lightweight fabric with a crook, puckered surface constructed in stripes. Plisse can also entitle both chemically and physically produced techniques; even the fabric of plisse is used for underwear. Essentially, itis a wrinkled fabric. It is slim, sophisticated, delicate, and simple to wear as an ensemble with a unique appearance. The plisse fabric is unlike any other fabric because of the ridges or stripes that give it a puckered, crinkled look.

What is Plisse Fabric Made of?

Plisse fabric is made of cotton, linen, viscose, rayon, or acetate fiber. The makeup process of plisse is chemically sophisticated. A pleat entitles a type that explicit the process of doubling fabric back upon and fixing it in position. A solution of NaOH applies, to the fabric.

Ultimately, this solution makes the fabric quite shrink and crook. Thus, how the clothing industry used to produce so many different types of textures and appearances, including dashes, pleats, ridges, and so on. The entire process is usually conducted on delicate, lightweight, thin fabrics; for instance, Polyester, cotton, linen, nylon, viscose, satin, etc.

Manufacturing Process:

The manufacturing process of Plisse fabric is a stride and sophisticated process. The manufacturer needs to go through a stereotype and lengthy process. However, producing fabric is not just the ending. Producers also need to inspect the quality of the fabric and remark on justification. The manufacturing process of Plisse is as:

Spinning:

In this initial stage, spinning entitles the transformation of a vast of scattered fibers (primary) into a specific unit of a stride length (flam). The spinning process consists of many different stages and relies on according to the traits of the fibers and the flam. This stage is structured to create a highly qualified yarn, delicate, smooth, and flexible with the minimum exquisiteness.

Dyeing Yarn:

After spinning the yarn, dyeing is a stage to conduct the manufacturing process of dying. In these circumstances, a process of transforming greige (a natural substance) yarn to turn into colored yarn, and combining color substances. This factor is considered to attain appropriate dyeing aggregation of the penetration of the dye and perfect stability. After all these, manufacturers need to be conscious of the fabric's original color even after washing so many times.

Weaving:

After working on the process of spinning and dyeing, the weaving stage generates the yarn to dissect together to form fabrics. Fabric is included when such web string overlaps the weaver yarn; it is a blend of the pattern, the form, and the weaver's competence.

On The Way of Finish Making Fabric:

After processing from the weaving, some sorts of systems remain to justify some remarks to improve the quality of the fabric. Dyeability, tint, texture, wettability, processability, and final appearance are the measurements of the remark, and this entire process is entitled to ennobling.

Final remark on Making fabric:

Passing all the previous stages, fabrics are ready for testing in a laboratory to check physically and chemically under a specific magnifying glass. In this circumstance, the producers and the inspectors check whether it has any defects or not. Finally, when they remark it as 100% appropriate and perfect, the fabric is ready to cut and package according to the customer’s requirement and amenity.

Finalized Fabric:

After inspecting the finalized fabric, producers conduct the process of making a plisse print. For that, they created an application of strong alkali of 100%. Then, the solution is applied directly to the pattern. After finishing this phase, the stuff must be washed to remove alkali. Consequently, all the areas where alkali occurred and was applied are turned into crook and pucker. There are bunches of material and stuff mixed to make plisse. After inspecting a sophisticated process, we got plisse fabric to use by hand.

Properties of Plisse Fabric:

|

Fabric Name |

Plisse |

|

Other Names |

Crepe, crisp, pucker |

|

Manufacturing Material |

Yarn, Fiber, Alkali, Sodium Hydroxide |

|

Possibility of Thread Count Variations |

Directly Relies on Base Component |

|

Fabric Breathability |

Higher Breathability |

|

Moisture wicking Abilities |

Usually, High |

|

Heat Absorption Ability |

Low |

|

Stretchability |

High |

|

Bubbling |

Low |

|

Recommendation of Washing Temperature |

Cold, Low Cycle, Handwash |

Properties

Characteristics of Plisse Fabric

The characteristics of Plisse fabric make it distinct from all its competitors of itself. Let's know about it:

- Appearance: Once pleated, it got waving outside the exterior appearance. It seems to have horizontal lines in its outer shape. Apart from this, the color of a plisse is quite innovative and gorgeous. After all these, plisse fabric is used for high fashion and decorative apparel.

- Maintenance: Being the fanciest fabric, it needs to take extra care. For example, while washing, you shouldn’t use high cycling in your washing machine; instead, lower cycling. Instead, use cold water while washing plisse fabric-related outfits.

- Comfortability: As a thin, delicate fabric, People use plisse as a regular outfit. However, it can also be found in summer shirts, sportswear, nightgowns, and so forth.

- Affordability: The affordability of plisse is on the budget. People could purchase it for under 10 dollars per yard. On the other hand, others might cost 20 dollars per yard. Regardless, plisse fabric is budget-friendly to purchase.

Applications of Plisse Fabric:

As a lightweight, soft, and delicate product, people use plisse fabric for various purposes.

- Asymmetrical skirts

- For button-up blouse

- Underwear

- T-shirt

- Sewing industry

- Home décor

FAQ:

Is a plisse fabric comfortable to wear?

Despite having a rough surface, plisse fabric has a smooth look that is almost wear-friendly and comfy. Even though it is very delicate, it is permeable. Compared to its rival, plisse fabric's polished look is far more comfortable to wear.

How do I take care of a plisse fabric?

Avoid wringing or twisting your garment made of plisse fabric to maintain its quality. Instead, handle the costume made of plisse with care while you wash it. Try to utilize the gentle cycle while using the washing machine.

Is plisse fabric suitable for the summer?

The fabric is significantly more comfortable for people wearing plisse fabric clothes in warm weather because of its delicate and thin appearance. Therefore, it is frequently used as a summer wedding gown. Regardless, summer attire is the primary application for plisse cloth.

Conclusion:

The pleating technique of the fine and smooth texture containing plisse is unknown, but the appearance and the fabric style make it distinct from its competitors. Answering the question, what is plisse fabric is exquisitely dictated through its texture, quality, fashion, and apparel.

Devoid of losing the exquisite quality of the plisse fabric, garments heavily use this fabric to retain customer retention. As a result, crinkle crepe, also known as plisse, is taking the place of the core place of the garments industry through its apparel day by day.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.