Usually, the fabric is made from either natural materials like cotton and silk or synthetic materials like polyester and nylon. But today I am going to discuss such a special fabric that is neither natural nor synthetic fabric. Guess what this fabric is! Yes, I am talking about Rayon. Then what is it made from? Rayon is a man-made fabric, but it is not entirely synthetic. I mean it's called semi-synthetic fabric. Read the article to know more about Rayon fabric.

Table Of Contents

What is Rayon Fabric?

Rayon is a semi-synthetic fabric that represents a low-cost alternative to silk. It's a cellulose-based woven or knitted fabric with a natural look. It employs a versatile and cost-effective fiber that lends itself to several applications. Rayon is an excellent breathable fabric and is available in a versatile range of colors.

Rayon fabric contains thin fibers that allow it to breathe better than other textiles. This fabric's lightness comes from the thin weave, which keeps it from adhering to the body in warm temperatures. Rayon is an ideal fabric for athletic and summer outfits since it is so comfy and cool to wear.

What is rayon fabric made of?

Rayon is a natural-based fabric made from cellulose. That means cellulose is the raw material of rayon fabric. Now the question is, what is this cellulose, or where is it found. Many of us are familiar with cellulose. Cellulose is a natural material whose primary source is the existing material like wood, especially pine, spruce, or snowflake.

How is rayon made?

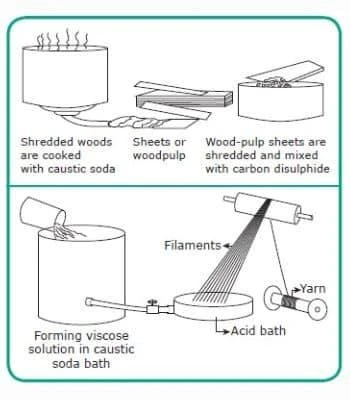

There are various ways in the production process of rayon fabric. The Viscose Rayon Manufacturing Process is described here:

1st Step:

The refined cellulose sheets are placed in a sodium hydroxide (NaOH) to produce alkaline cellulose. These sheets are then cut into pieces after drying. These are then placed in a metal jar for 2 to 3 days, whose temperature and humidity are controlled.

2nd step:

The crumbs are then mixed with carbon disulfide and churned. The outcome is orange crumbs that have been soaked in caustic soda. It's the outcome of a viscose solution with a honey-like appearance and feels. Impurities could be removed from the solution. Then kept in vats for 4 to 5 days.

3rd step:

The fibers are prepared to cut into skeins after acid treatment. Several spinning processes can be employed depending on the yarn type. Spinning lowers the diameter of fibers and makes the fiber more regular in shape, strength, and durability of the filament.

In a top spinning combustion chamber, the filament is then lowered to the Topham box, culminating in a cake-like string to the Topham box. Following that, the strings are cleaned, bleached, rinsed, dried, and wrapped into a cone or spool.

4th Step:

The fibers are ready for post-treatment chemicals when they have been cured enough. Then the fiber is prepared for several weaving operations to generate the fabric.

Types of Rayon Fabric

Based on the source of raw materials, there are mainly 5 types of Rayon fabric available. They are as below

- Viscose Rayon

- Modal

- Lyocell

- Bamboo Rayon

- Blended Rayon

Based on fabric manufacturing technique, rayon fabric can be divided into two category as below

- Woven Rayon

- Knitted Rayon

Properties of Rayon

|

Fabric |

Rayon Fabric |

|

Composition |

Cellulose |

|

Breathability |

High |

|

Moisture-absorbent |

Low |

|

Stretchability |

Low |

|

Moisture-absorbent |

High |

|

Prone to bubbling |

Low |

|

Washing temperatures |

Cold |

|

Used in |

Shirt, Skirts, Tunics, Dresses, Lingerie, Sportswear, tire cables, Medical Application |

Application of Rayon Fabric

The textile sector is the most common application for rayon fabric. The most prevalent application for rayon is in the manufacture of blankets, sheets, and other apparel and homeware applications. Rayon is the best fabric for sports and summer outfits since it is casual and comfortable to wear. This fabric may also be used to make medical goods and tire cables. It is used to create low-cost, lightweight, and convenient apparel.

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.