Table Of Contents

What is weaving?

Weaving is the most common and oldest method of producing textile fabrics. In this process, the fabric is made by the interlacement of two sets of yarns on the loom, weaving machine. While the lengthwise yarns are called warp yarns and widthwise are weft yarns.

Basics of weaving

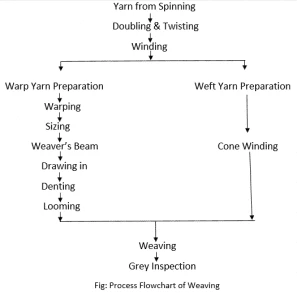

Generally, there are three types of processes of manufacturing fabric, weaving, knitting, and non-woven. When the fabric is produced by using the weaving method, then it’s called woven fabric. Before knowing about weaving in detail, it’s wise to know the process flowchart of weaving.

Process FlowChart of Weaving

Every process of weaving

Now let’s briefly describe every process of weaving.

a) Yarn Preparation:

After yarn manufacturing, the yarn is collected from the spinning industry. But the condition of yarn in this stage is not good enough for weaving. Therefore, it’s necessary to process the yarn further to make it suitable for fabric formation. These preparatory processes are known as yarn preparation.

b) Winding:

As we know, weaving requires two sets of yarns, warp and weft. Both yarns have to be wound onto the right package that is suitable for further processing. The process of transferring the yarn from one type of package to another is called winding.

c) Warping:

The preparation of warp yarn is more complicated than weft yarn. This is because warp yarns undergo many processes like warping, sizing, drawing, denting, and tying. However, warping is the process to transfer many yarns from creels to the warp beam, known as weaver’s beam, which is later installed on a weaving machine.

d) Sizing:

The warp yarns are not still good enough for the weaving process. They require to be strong and smooth enough to be subjected to some subsequent processes in weaving. To obtain these properties, an adhesive protective layer is applied to the warp yarns before weaving, which is called sizing or slashing.

e) Drawing in:

The process of pulling warp threads through the weaving elements like drop wires, heddles, and reed of the weaving machine is called drawing in.

f) Denting:

Denting means drawing the warp threads through the dent according to the reed plans.

g) Looming:

After depletion of the ends of the existing warp beam, if there is no change in design, the ends of the old beam are cut and tied to the ends of the new warp beam. This process is called looming or tying in.

h) Weaving:

After all, the preparation is done, the weaving gets started.

i) Grey Inspection:

Then the woven fabric is sent to the inspection department to inspect visible faults.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.