In this article, we will be discussing everything about the classification of textile fiber with examples. So, let’s dive into the topic.

When you speak about textile fiber it will always come to the fabric. Because fiber is the basic component for fabric making we think you know the necessity of fabric as you use it in your daily lifestyle.

Fiber is actually anything that has the capability of being made into fabric. It is the finest visible unit of textile fabric. Experts say, “A fiber is a pliable hair-like strand that is very small in diameter in relation to its length.” Fiber is the building block for making textile yarns and fabrics.

Table Of Contents

Textile Fiber Classification

Fibers are very small and lightweight materials. It can be derived from various sources and can be found in different lengths. Depending on these types of aspects fibers can be classified in different ways.

Classification of textile fiber according to their sources

According to where the fiber is coming from it can be classified into two major divisions.

1. Natural Fiber:

Natural fiber comes from nature, you can guess this from the name. The fiber that is produced naturally from plants, trees, or animals and later on twisted into yarns is called natural fiber. They are not as uniform as synthetic fibers and are easily affected by changes in the climate.

Types of Natural Fiber

Natural fibers basically come from 3 sources.

a. Plants Fiber / Vegetable Fiber

This type of natural fiber's main source is different plants and trees.

Example:

- Cotton: It is the most popular natural fiber that comes from plants. It is made of pure cellulose.

- Jute: Jute is the strongest fiber that comes from the jute plant. India and Bangladesh are the main producers of this kind of natural fiber.

There are many more like flax, hemp, and sisal plants that produce natural fibers.

Vegetable Fiber is classified into 3 categories:

- Seed: Cotton, Kapok, Coir

- Bast: Jute, Flax, Remie

- Leaf: Abaca, Sisal

2. Animal

Natural fibers are often made from using animal body hair. Animals are the source of this type of fiber. This type of fiber is heavily used in textile industries.

Example:

- Silk: Silk is the most popular animal fiber. It has a great look with good properties. This fiber is produced by silkworms.

- Camel hair: It is one of the softest and best quality animal fibers that is made from camel hair.

- Cashmere fiber: A kind of goat is the main source of this type of fiber. It is the most pricy animal fiber.

Furthermore, wool and mohair are also very well-known names in this category.

3. Mineral: Asbestos

b. Man-made fiber or Synthetic fiber

Synthetic fibers are made by combining different chemicals in the right way. Chemicals are melted and spun into continuous filament fibers. This process is called the polymerization of monomers.

Man-made fibers can be classified into two major groups.

A. Synthetic fiber

Since the eighteenth-century fiber manufacturing has got a new speed. Various chemicals started to be used for manufacturing fibers in that era of the product industrial revolution. This type of fiber polymer does not directly come from nature.

Example:

- Polyamides: Nylon

- Polyester: It is a very well-known synthetic fiber made by a long reaction chain. Example: PET

- Poly-Vinyl Derivatives: Polyacrylonitrile, Poly Vinyl Chloride, Polyvinyl Alcohol, Polytetrafluro ethylene & related polymer, Polyvinylidine dinitrile (PVDN), Polystyrene, Miscellaneous

- Poly-made: Poly-made fiber is made from carbon atoms it is used for making mostly undergarment fabric. Example: Polyolefin, Polyvyl Acrylic, etc.

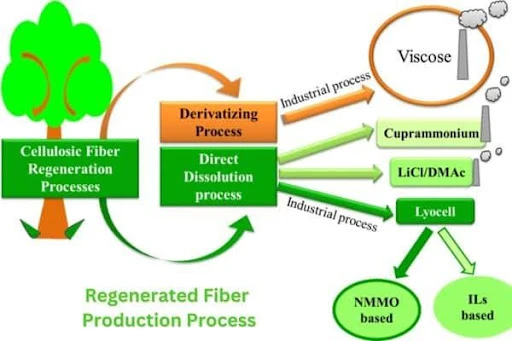

B. Natural polymer fiber / Regenerated Fiber

This type of man-made fiber raw material comes from cellulose, protein, or material like gold, iron, etc. Various metal strands are used to make fibers. Maybe the main element comes from nature but you can easily distinguish them.

Example:

c. Other

Glass, Carbon fiber Aramid, and Metalic are classified separately.

Classification Of Textile Fiber According To Their Length

Fiber length is a very important factor in having quality yarn. Very short fibers can not produce the best quality yarns. So it is important to choose the right size fibers for producing impressive fabrics.

The length of the fiber can be divided into 2 categories.

1. Staple Fiber

Staple fiber is comparatively short. They can be man-made or natural fibers and measured in fractions of inches. Normally their length is ¾ to almost 18 inches. The silk fiber is an exception as they are more lengthy than other natural fibers. They can be 350-1200meters long. A staple fiber's length will always be limited.

2. Filament fiber

The length of filament fiber is unlimited as most of them are man-made. So the length is determined by humans and measured in meters or yards. Most man-made fibers are filament fibers. But if there is any need it can be used as staple forms.

Synthetic fibers can be kilometers long sometimes which makes them filament fibers. Filaments can be used as staple fiber but staple fiber can not replace filament fiber.

Classification of textile fiber according to their use

As we are talking about textile fiber it is obvious to discuss the types of fiber according to their use. Not all fibers are made for the same purpose. Some are produced for use heavily in the making of garment fabric and some are not.

Fibers can be classified into two types according to their utility.

1. Major Textile fibers

Fibers like cotton, silk, polyester, and nylon are produced for making fabric. You can find garments made of 100% cotton or 100% polyester. The fibers that are capable of making a whole garment are major textile fibers.

2. Minor Textile fibers

This type of fiber is mixed in the fabric to have a specific property. They are mostly not capable of making a dress of their own. By mixing them with major fibers delicate items are produced with special properties. Metallic fibers, spandex, and bamboo fibers are the most known names in this category.

Properties

Textile fiber must have some qualities. Without meeting those the fiber cannot be used in the textile products industry. Properties of Textile Fiber are as:

- They must show good tenacity properties. If the tenacity is low, fiber can’t be made. They will not bond with each other firmly.

- The flexibility of fiber needs to be good for more durability.

- The fiber must have better properties to regain its shape.

- Moisture properties also need to be perfect for producing high-quality and comfortable textile fabric.

- Luster and color are always important factors for fabrication. So textile fiber must have these qualities.

Final Words

You can find different types of categorization in different resources. Mostly the classifications are done depending on their birth and length. There are a few differences in different experts' opinions. But mostly they are the same just Grouping is done a bit differently. The most standard division for textile fibers is natural and manmade fibers. We discussed different types of classification for a clear idea about fibers.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.