Printing can be described as the controlled placing of defined areas of color onto a substrate. It is essential that colorant be applied to the fiber surface first, usually through the use of a printing paste. If it is a soluble dyestuff, it must be diffused onto the fiber. The colorant must then be fixed in place and finally, excess infixed color has to be washed out. There are a lot of printing methods and printing styles. In this article, I will discuss a modern printing method that is the digital printing method on fabric. Let’s First of all, we know what is digital fabric printing method.

Table Of Contents

What is digital fabric printing?

Digital fabric printing method is a modern printing method on the fabric where printing designs directly onto fabric by using specialized inkjet printing. In the digital fabric printing method, there is no need for a printing plate.

This printing method has some special advantages over traditional printing methods. Day by day, the digital fabric printing method is becoming popular in the textile industry.

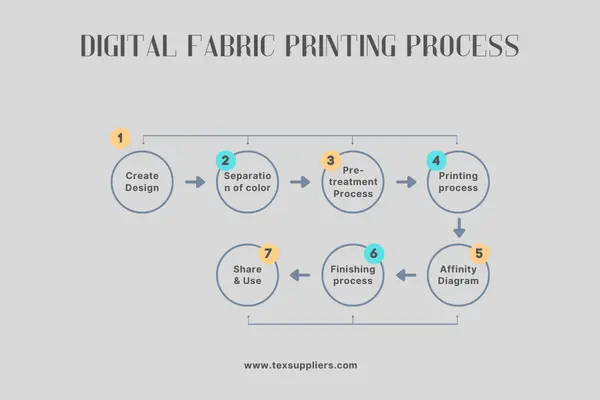

Digital Fabric Printing Process:

1. Create Design:

At first, the design is created. The design may be sent by the buyer. Sometimes buyers give the design requirements and give instructions to create the design. Design is created by using software like Adobe Photoshop or Illustrator.

2. Separation of color:

After completing the design, the color is separated. It is essential to separate colors into different color channels if the design involves multiple colors. This color separation process ensures that each color is printed accurately.

3. Pre-treatment Process:

The pre-treatment process depends on fabric types. The pre-treatment process improves the absorbency of color. In the pre-treatment process, a chemical or coating is applied to the fabric surface.

4. Printing process:

At first, pre-treated fabric is loaded onto the digital fabric printer machine. The printing head of this machine is like a common paper printer machine. But this head is designed for only fabric printing. The printing head of this machine prints the design on the fabric according to the inputted design. Different types of color or inks are used for printing such as pigment, dye-sublimation, or reactive inks.

5. Fixation Process:

In the fixation process, ink is set on the fabric. Here heat is applied to the printed surface. The fixation process improves the resistance to washing and fading of the fabric. The fixation process also depends on the types of ink or color used.

6. Finishing process:

In the finishing section, some finishing process is carried out on the fabric such as washing, drying, or heat pressing. The finishing process improves the fastness properties of printed fabric.

7. Quality check:

In the quality control section, printed fabrics are checked to ensure the quality and buyer requirements. In this section ensure that the printed fabric meets the desired color and overall quality standards.

Advantages of Digital Fabric Printing Machine:

1. In this printing method, the design can be easily customized and printed on demand. It is possible for small production runs and personalized products.

2. In the digital printing method, there is no need to create printing plates or screens. So this method reduces material waste and setup costs.

3. Digital printing consumes fewer resources and produces less waste compared to traditional printing methods. So we can say this method is environmentally friendly.

4. This method reduces production lead time as there is no need to make screen setups, screen preparation or engraving plates.

5. It enables printing small quantities or even single pieces.

However, we can say, that digital fabric printing has revolutionized the textile industry by creating high-quality printed fabrics for a wide range of applications, such as apparel, and home textiles.

Disadvantages of Digital Fabric Printing:

1. Color matching of this method is challenging because of variations in fabric types, and ink formulations.

2. All types of fabric are not suitable for digital printing.

3. Initial investment cost is high.

4. This method is not suitable for large production.

Conclusion:

Overall, digital fabric printing offers a versatile and cost-effective solution for producing high-quality printed textiles. In this article, I tried my best to present the overall process of digital fabric printing with advantages and disadvantages. If you have any questions, please let me by comments box.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.