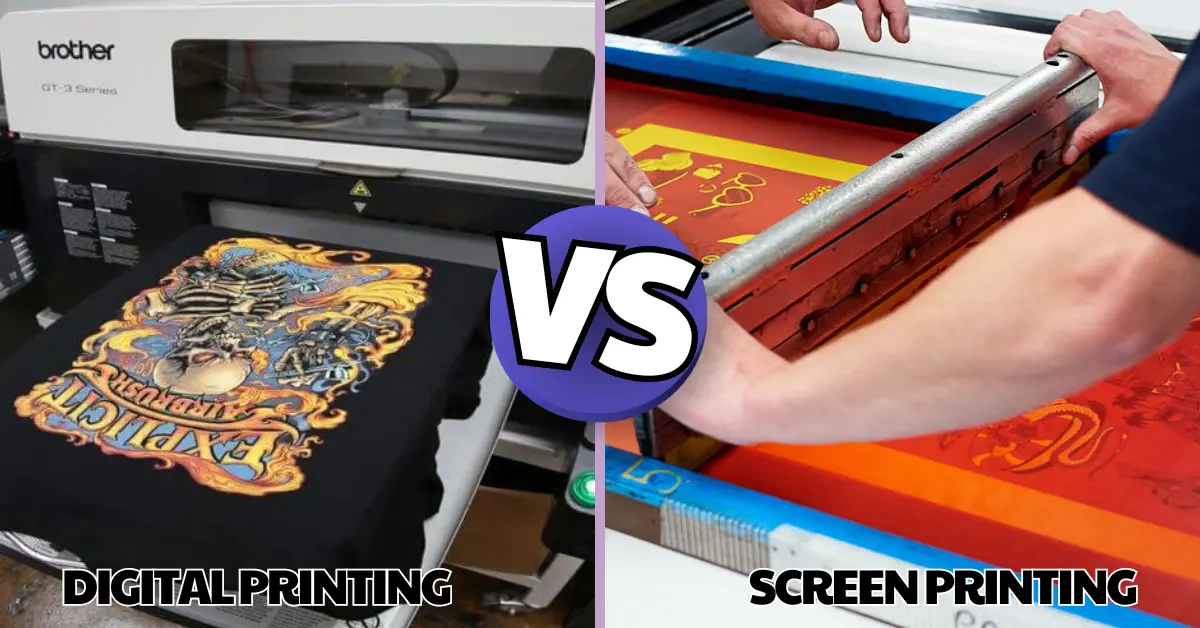

The next-generation printing process is unthinkable now without engaging digital and screen printing methods in textiles. They are significantly diverse and distinct compared to the method of conventional fabric printing. Entrepreneurs have started to invest in technology to meet the demands of both domestic and international market spheres.

Embracing these two new printing technologies represents the advancement in textile industry sources. In this article, we will learn how the two printing methods, digital, and screen, differ from each other.

Table Of Contents

What is Digital Printing?

Digital printing refers to creating digital images on physical surfaces in cloth. The created design gets directly printed on the fabric from the computing device. There are no additional steps in this process. There is the use of a dye sublimation printer to print designs on fabric.

This printer uses heat to transfer the design onto the fabric. Pre-treating the fabric is suggested. It helps to ensure the ink is put on the fabric well. In the pre-treatment process, several colors can be applied.

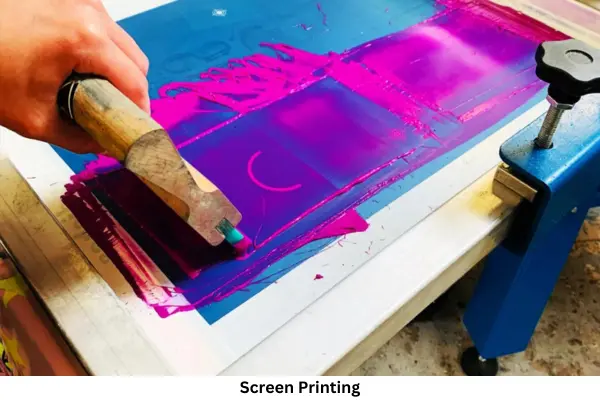

What is Screen Printing?

Screen printing also referred to as the silk screen printing method, refers to the process where there is the transfer of a stenciled design on the surface of fabric using ink, a rubber blade, and a mesh screen.

Here, the process starts with the creation of a stencil on the mesh screen. Ink pushing on the surface creates the design. The surface here means the fabric, paper, metal, plastic, wood, and others. One of the popular techniques of printing is screen printing as there can be the use of a variety of colors.

The Difference Between Digital and Screen Printing

|

Area of Difference |

Digital Printing |

Screen Printing |

|

Best for |

Ensuring details on items with a smaller quantity |

Printing on dark-colored fabrics |

|

Used for |

Printing textiles with modern and crisp finishes |

Printing textiles, latex, wallpapers, balloons, and plastic |

|

Durability |

High |

|

|

Versatility |

Great for flexibility and sharp finish |

Design placement tends to be versatile in terms of putting on a different position. |

|

Personalization |

Possible. It is perfect for personalized design |

Not possible. |

|

Per Batch Design |

1 Design per Batch |

|

|

Color Matching |

The color appears slightly different |

The color comes out good |

|

Cost |

Cost Effective comparatively. It is cheaper for small quantities. |

The initial costs are high but it becomes cheaper for large batches |

Conclusion

To sum up, digital and screen both are popular methods to transfer the design on the fabric surface. Where digital printing involves the use of a digital printer, screen printing uses a screen or a stencil for each color to create the design.

Ink gets integrated into these screens using the squeegee. Digital printing is cost-effective compared to screen printing as the initial setup cost is not there. Screen printing holds the color well but creates abrasion over frequent washing

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.