Table Of Contents

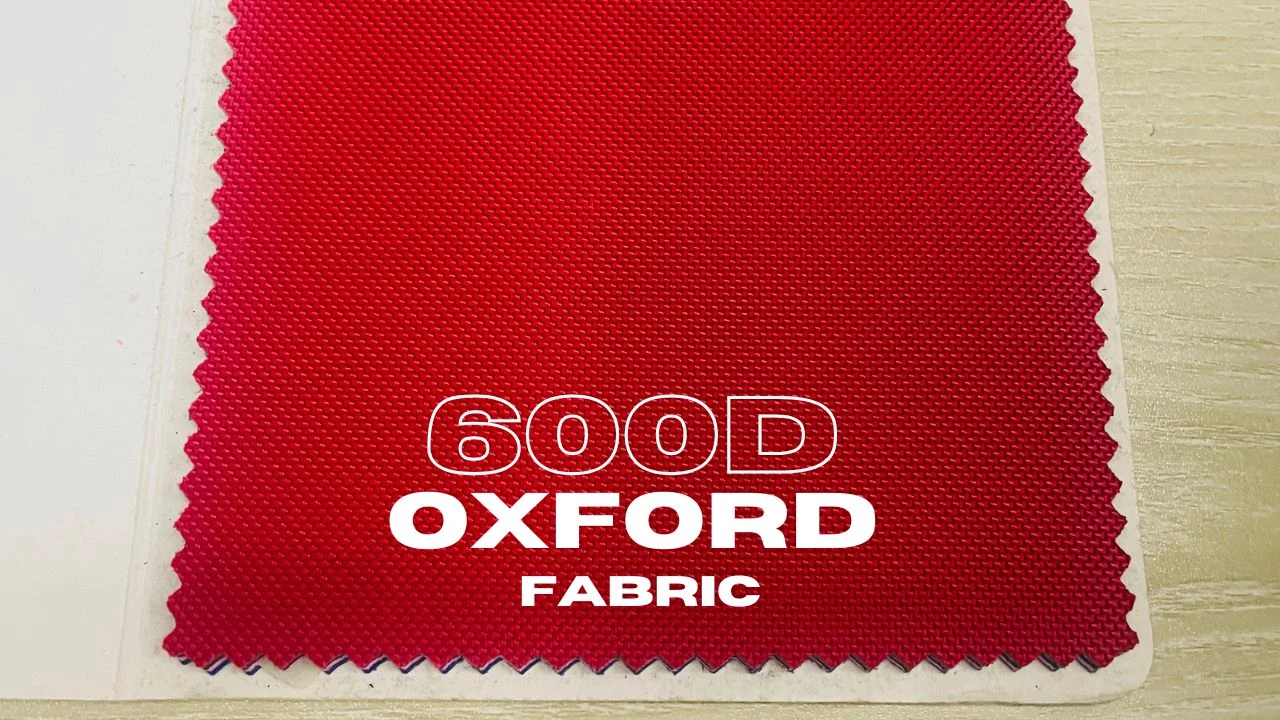

What is 600D Oxford Fabric?

600D Oxford fabric is an Oxford weave made of polyester or nylon fabric with a 600 denier (D) thickness. The term “Oxford” describes the specific basketweave pattern used in its construction. It gives the fabric both durability and flexibility.

|

Characteristics |

Details |

|

Fabric Name |

600D Oxford Fabric |

|

Fabric Also Known As |

Oxford Cloth, 600D Polyester Fabric, 600D Nylon Fabric |

|

GSM Range |

200-300 GSM |

|

Composition Range |

100% Polyester, 100% Nylon, sometimes blended with Nylon |

|

Construction Range |

Basket Weave |

|

Manufacturing Process |

Woven, followed by PU or PVC coating |

|

Possible Thread Count Variations |

600D (denier), 1200D (heavier version) |

|

Full Width |

57/58” or 59/60” |

|

Cuttable Width |

56" to 59" |

|

Fabric Breathability |

Low to moderate |

|

Additional Coating Variations |

PU (Polyurethane) Coating, PVC (Polyvinyl Chloride) Coating, TPU (Thermoplastic Polyurethane) Coating |

|

Moisture-Wicking Abilities |

Low to moderate |

|

Heat Retention Abilities |

Moderate |

|

Stretchability |

Minimal |

|

Prone to Pilling/Bubbling |

Low |

|

Country Where Fabric Was First Produced |

China |

|

Biggest Exporting Country Today |

China |

|

Recommended Washing Temperatures |

Cold to warm (30°C to 40°C) |

|

Common Applications |

Backpacks, tents, awnings, luggage, upholstery, outdoor furniture covers, sports gear |

The "600D" indicates the weight and density of the yarn used. The "600D" label means that the weight of 9,000 meters of this yarn is 600 grams. This fabric is primarily made using 600D polyester yarn or 600D nylon yarn. Polyester and Nylon are well-known for their durability and strength. It makes a relatively heavy-duty fabric compared to lighter denier options like 300D or 400D.

Types of 600 Oxford Fabric

In the market, there are two common types of 600D polyester Oxford fabrics: 600D*600D and 600D*300D. The 600D*600D version is made with two 600 Denier yarns woven both in the warp and weft directions. It provides a higher density and more rigidity compared to the 600D*300D fabric, which uses one 600D yarn and one 300D yarn.

Difference

The key difference between the two versions lies in their density and gram weight. The lower the denier number, the lighter the fabric, with less strength and a lower price. The 300D fabric is softer, lighter, and has lower density than the 600D fabric, which makes it suitable for different uses. 600D Oxford fabric is heavier, more durable, and ideal for applications requiring strength and toughness, while 300D Oxford fabric is better suited for lighter, softer applications.

This fabric is commonly made from 100% polyester. But it can also be found in nylon variations. The 600D weight provides it with a tough, resistant texture that makes it ideal for products requiring high durability.

Key Features of 600D Oxford Fabric

Durability

The most significant feature of 600D Oxford fabric is its durability. With its thick yarn, the fabric resists wear and tear, making it perfect for heavy-duty applications. The 600 denier yarn gives the material its rugged and tough structure, which can withstand frequent use, abrasions, and outdoor conditions.

Water Resistance

One of the primary reasons 600D Oxford fabric is so popular is its water-resistant capabilities. Often coated with PVC (Polyvinyl Chloride) or PU (Polyurethane), the fabric can effectively repel water, making it ideal for outdoor products like tents, awnings, and rainwear. The coating prevents moisture from seeping through, ensuring the fabric remains dry even in damp environments.

UV Resistance

Many variants of 600D Oxford fabric come with UV-resistant coatings, which help prevent fading and degradation from sunlight exposure. This makes it a great choice for outdoor furniture, boat covers, and other applications where constant sun exposure is a factor.

Breathability and Flexibility

Despite its strength, 600D Oxford fabric is relatively flexible and offers decent breathability. It’s not as breathable as lighter fabrics like cotton, but its weave allows some airflow, making it suitable for items like backpacks and jackets where both protection and ventilation are needed.

Abrasion and Tear Resistance

The basket weave structure of Oxford fabric provides extra strength, making it highly resistant to tears and abrasions. This is particularly useful for products like luggage and outdoor gear, where the fabric will likely be exposed to rough handling.

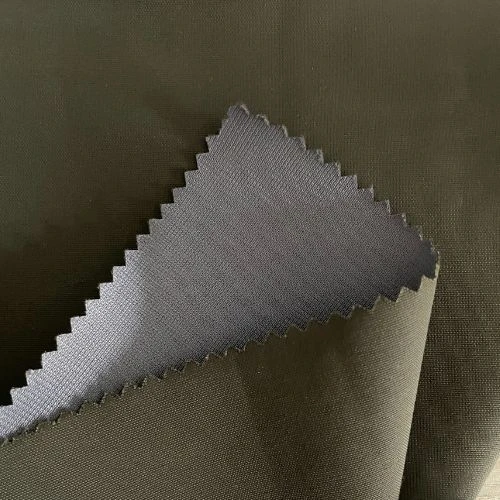

Popular Coatings and Finishes for 600D Oxford Fabric

PVC Coating

PVC (Polyvinyl Chloride) Coating adds a layer of waterproof protection to the fabric, making it ideal for heavy-duty outdoor applications like tarpaulins and covers. The PVC coating makes the fabric more rigid and completely waterproof.

PU Coating

For a lighter, more flexible finish, PU (Polyurethane) Coating is often applied. This coating also provides water resistance but allows the fabric to remain softer and more pliable. PU-coated 600D Oxford fabric is commonly used for backpacks, tents, and rainwear.

TPU Coating

TPU (Thermoplastic Polyurethane) Coating is another finish that enhances the waterproofing and flexibility of the fabric while maintaining its light weight. It’s a popular choice for outdoor sports equipment and luggage.

Applications of 600D Oxford Fabric

600D Oxford fabric is used in a wide variety of technical products:

- Backpacks: The strength and water resistance make it perfect for travel and hiking bags.

- Tents and Awnings: Its UV resistance and waterproof qualities make it ideal for outdoor shelters.

- Luggage and Travel Gear: The tear-resistant nature of the fabric ensures it can withstand rough handling.

- Outdoor Furniture Covers: Its durability, combined with UV and water resistance, makes it a great material for protecting furniture.

- Upholstery: For heavy-use upholstery, 600D Oxford fabric offers both toughness and style.

- Sports Gear: Many sports bags and protective covers for equipment use this fabric due to its abrasion resistance.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.