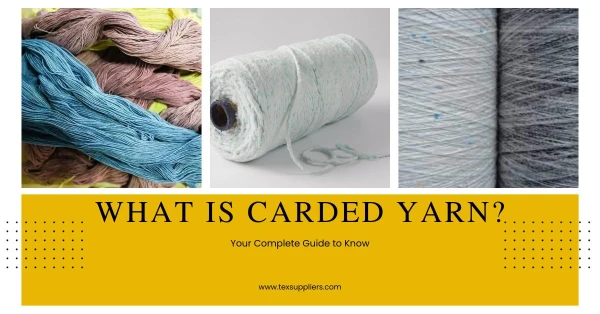

There are a few yarns out there that help to make ropes. Carded Yarn is one of them. Be it for knitting, weaving, or even crocheting, we cannot just think beyond the application of carded yarn. These carded yarns are not combed but rather made of a versatile variety of fibers. This entire article is about what carded yarn is and its every in and out including characteristics, applications, and whatnot.

Table Of Contents

What is Carded Yarn?

Carded Yarn refers to the unerupted yet lengthy interlocked fiber span. They get made using a process where fibers produce card strands. The interesting fact is that the carded yarn is not combed because they have no such uniform finishing.

You may hardly get these cheaper yarns comparatively. Although carded yarns are unerupted in nature, they consist of short, medium, and long fiber lengths. Also, you can denote carded yarn as the short stapled yet low-quality fiber material yarn. The name “Carded” is derived from the spinning section and operation named “Carding.” So, you can ultimately say that the yarn that forms through the carding process is the carded yarn.

What is Carded Yarn Made of?

Carded yarn is a cotton-made yarn with a wide variety of fibers included. This yarn does not have much great potency, which results in the yarn being less shiny. They tend to be coarser, and the quality is low in nature.

If you take the yarn in hand, the hands will feel hard in case of this yarn. The strength is not much comparatively also. You may question its wear and tear facilitating. Well, carded yarns in the case of clothes, withstand a moderate to high wear and tear nature. In terms of color fastness, carded yarn does not have such an important change. Besides, this yarn produces lower grams per square meter of fabric.

Manufacturing Process of Carded Yarn

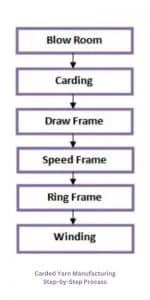

Carded Yarn Manufacturing Process Flow Chart:

Input product--- Process of Manufacturing---Output product

Fiber --------------- Blow Room-------------Lap

↓

Lap -------------- Carding --------------Card Sliver

↓

Card Sliver ----------- 1st Drawing Frame -------------- Drawn Sliver

↓

Drawn Sliver --------- 2nd Drawing Frame -------- Drawn Sliver

↓

Drawn Sliver ----------- Simplex-------------- Roving

↓

Roving --------------Ring Frame------------ Yarn

↓

Yarn -----------Cone winding ---------- Cone

↓

Cone ------------Reeling ----------- Hank

↓

Hank------------ Bundling ----------- Bundle

↓

Bundle ------------- Baling ------------ Bale

The Flow chart of Carded Yarn manufacturing is the Following:

|

Input Facts |

Process or Machines that Have Been Used |

Output Facts Output |

|

Bale |

Blow room |

Lap |

|

Lap |

Carding machine |

Silver |

|

Silver |

Breaker draws frame |

Silver |

|

Silver |

Finisher draw frame |

Silver |

|

Silver |

Roving frame/simplex |

Roving |

|

Roving |

Ring frame |

Carded yarn |

Brief Spinning Processes:

- Blow Room: The first stage of the spinning process.

- Carding: The Process here that determines yarn features.

- Draw Frame: The machine where drafts and double downs get carried out.

- Roving Frame: Products that get delivered by a roving machine.

- Combing: A process where high-quality yarns get introduced. Short fibers of carded yarns become a hindrance in the spinning process during finer counts.

- Ring Frame: This frame tends to draft the roving based on the required and achievable fineness. To form yarn that consists of proper count and strength, twisting draft-making is necessary.

- Cone Winding: The final stage in the spinning process refers to as the cone winding. This process is essential to understand the personnel handling the department.

Properties

|

Yarn Name |

Carded Yarn |

|

Manufacturing Materials |

Cotton |

|

Yarn Durability |

High |

|

Resistance to High Temperature |

Yes |

|

Water-Absorbent Ability |

Less |

|

Yarn Strength |

Low |

|

Yarn Shine |

Not Shiny |

|

Mostly Used in |

Production sewing, Making Rope, Crocheting, Embroidery. |

|

Low Tendency to Peel (Rough Count) |

++ |

|

Uniform Fabric Appearance |

++ |

|

Clear Structures |

++++ |

|

High Abrasion Resistance |

++++ |

|

High Utilization of Dyes |

+++ |

Characteristics

As we have said before, carded yarn is comparatively cheaper. As a result, the carded yarn consists of several characteristics to define.

- Cost: Carded Yarn is a low-cost Yarn

The only benefit of getting a carded yarn is the low cost and cheaper production cost.

- Hard in hand-feeling

In terms of feeling the yarn, the carded yarn seems to be hard.

- Low Strength Ability

Carded yarns’ strength ability aligns with the fiber. Also, it transfers the fibers into a thin web to bring them together as a soft fiber.

- Low Quality

The quality of the carded yarn is less as it contains both neps and short fibers. Carded yarns are highly used for any kind of fabric material for average count.

- High Dyeing and Knitting Wastage

Since the carded yarn has high dyeing and knitting wastage, it hurts the environment.

- Hairy in Nature

Although the carded yarn is a little hairy from the outlook, the yarn lacks shine compared to combed yarn.

- Not a Better Water-Absorbent

- Low Count Yarn (About 10-45)

- Produces Lower Quality Fabric

- Irregular

Applications

Before describing the application areas of the carded yarn, we must get to know about the quality of the fabric made of carded yarn. Unfortunately, the carded yarn produces a very low-quality fabric with low production costs. For terry towels, carded yarns are one of the ideal yarn types. Terry towels made of carded yarn, have high absorbency and quick drying ability. Carded yarn tends to be used for knitting, crocheting, and weaving. There is no other raw material except for cotton. These yarns tend to be of wide variety.

Conclusion

The carded yarn has no combing machine to separate short fibers during the spinning process. As a result, carded yarns tend to have a shorter fiber and a little hairy appearance. Carded yarn is economical in terms of cost. Although the shrinkage is higher in carded yarn, it is not defined as important in towel making. Carded Yarn is cotton-material that is well-prepared for spinning to get into thread and yarn. Industrially made carded cotton gets prepared on a huge spinning drum. These drums are capable of processing cotton at high volumes. Carded cotton yarns are also available for rapid processing where minimal time is required.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.