Printing types are there in many ranges, to be applied on fabric, textiles, and garments. Days of plain merchandise are gone. Merchandise is now available in printed textiles. These are customized prints on fabrics.

Based on quality, efficiency, and durability, fabric and patterns are different, and so are printing methods. In this article, we have listed down all the printing on fabric types in one place to help you choose the best one.

Table Of Contents

What is Printing in Textiles?

Printing in Textiles means the process of applying colors to any fabric with a pre-determined pattern and designs. Printing refers to the Latin word meaning ‘pressing.’ It denotes the application of pressure. Textile printing refers to the process of applying color to the fabric in chosen patterns or designs.

Printing in textiles produces attractive designs on the fabric. Usually, this printing reflects only one side of the textile. There are numerous printing methods to be applied on the fabric surface transferring the dyestuff and chemicals.

11 Different Types of Printing on Fabric

There are almost 11 different types of printing methods in Textiles. All these methods are applicable to use on fabric for different purposes, designs, and techniques. For instance:

-

Stamp Printing: In this printing method, there is the creation of a stamp. It is then used to imprint onto the fabric. Here, your design gets cut into the stamp and dipped into the ink. With a presser, you can transfer the printing from the stamp to the textile.

-

Stamp printing is kind of similar to another technique named block printing. But there are differences. Stamp printing applies to any textile surface using different kinds of stamps. It can be wooden, or it can be rubber, etc. Not all stamp printing is block printing in this regard.

-

Transfer Printing: Here, the transfer paper comes into use. It is a specialized paper that can be brought from most stationers. All you need to do is to use any printer to print the design onto the transfer paper. Now, apply this paper to the chosen fabric using a steam iron. It is a technique, not a permanent method of fabric printing.

-

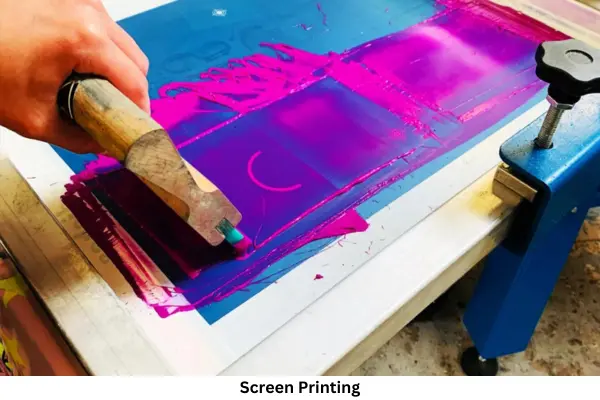

Screen Printing: It is one of the most popular printing types in the business. This method involves using a stencil, and a nylon mesh, to create the print design. This method is only applicable to each screen with the production of fantastic replications.

-

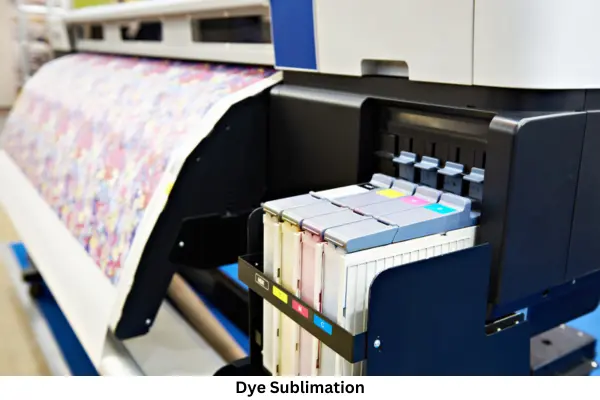

Dye Sublimation: It is a multi-step process to get the best result on the fabric. Here, you need to print designs onto the thermal transfer paper. It is called a dye sublimation paper. In dye sublimation, there is the use of both heat and pressure to create the bond between the ink to the fabric fiber.

-

Pigment Printing: It is one of the popular printing techniques to use on cellulose fibers. It makes an ideal use to apply on natural fabrics. It is the fabric printing method to be used on synthetic materials. Besides, it involves the application of the dye to the fabric part.

-

Reactive Printing: It is another fabric printing method that is heat-activated. Reactive printing is done by pre-coating the fabric. It uses a binder and a printing additive. It prints a dye, and wax onto the fabric. It is also about coating the fabric with designs to create a reaction that bonds the design to the textile.

-

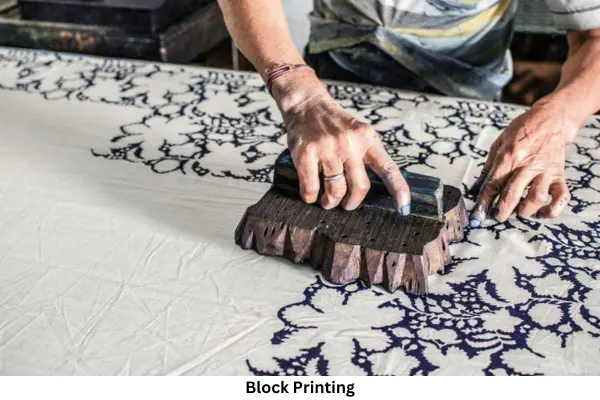

Block Printing: In this method of block printing, the pattern gets cut into the shape of the wooden block. Then, this block uses a print paste to apply on the fabric surface with the use of pressing. The process gets repeated with different designs, colors, and patterns. Block printing only comes in the wooden carved block shape, not any other formats.

-

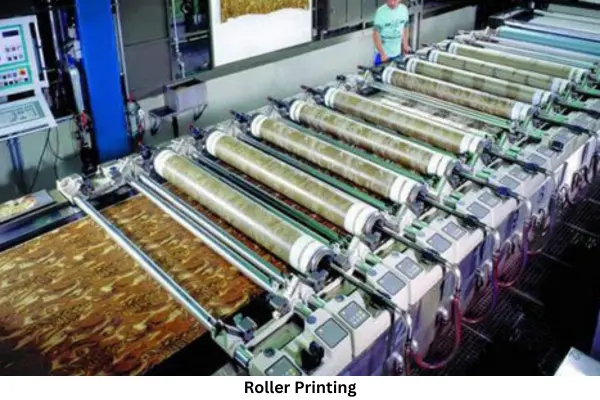

Roller Printing: Roller printing refers to the preferred long production run with high speed. It is a versatile technique that consists of copper-faced rollers. A separate printing roller is there to print each color. Each roller rotates over the fabric under pressure. It happens against the iron pressure roller.

-

Heat Transfer Printing: This is another transfer printing technique that involves the transfer of the design from one medium to another. In this common form, heat transfer printing is used. Here, the design is printed onto the fabric using a special paper that uses conventional printing machinery.

-

Ink-Jet Printing: Ink-jet printing uses commercially available fabric for the graphic market. It is the modern way of printing textile fabric. Printing machines are used in this process. It involves two classes: Drop on Demand and Continuous Stream.

-

Digital printing: This printing method brings revolution to fabric printing. It offers precise designs to print onto the fabric surface. Besides, there is the use of specialized inkjet printers that have transformed the textile industry. It is easier and more efficient to produce customized fabric with vibrant colors and patterns.

Conclusion

To sum up, almost all popular printing methods in textiles are listed in this article. Some manufacturers help you analyze the pattern and recommend suitable printing techniques.

Almost all different printing types come with pros and cons. Despite their cons, they are available to apply different printing techniques as per the company’s style.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.