TC is a Tetoron Cotton blended fabric with more than 50% polyester fiber or yarn in total combination with cotton. Tetron is a Japanese name for polyester that evolved 40 years ago. Today, TC is made of 65% polyester and 35% cotton. However, in this article, we will explain every aspect of TC fabric, including its manufacturing process, dying process, types, features, and applications.

Table Of Contents

What is TC Fabric?

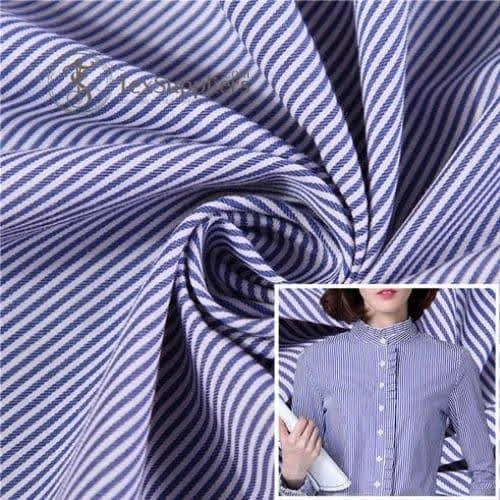

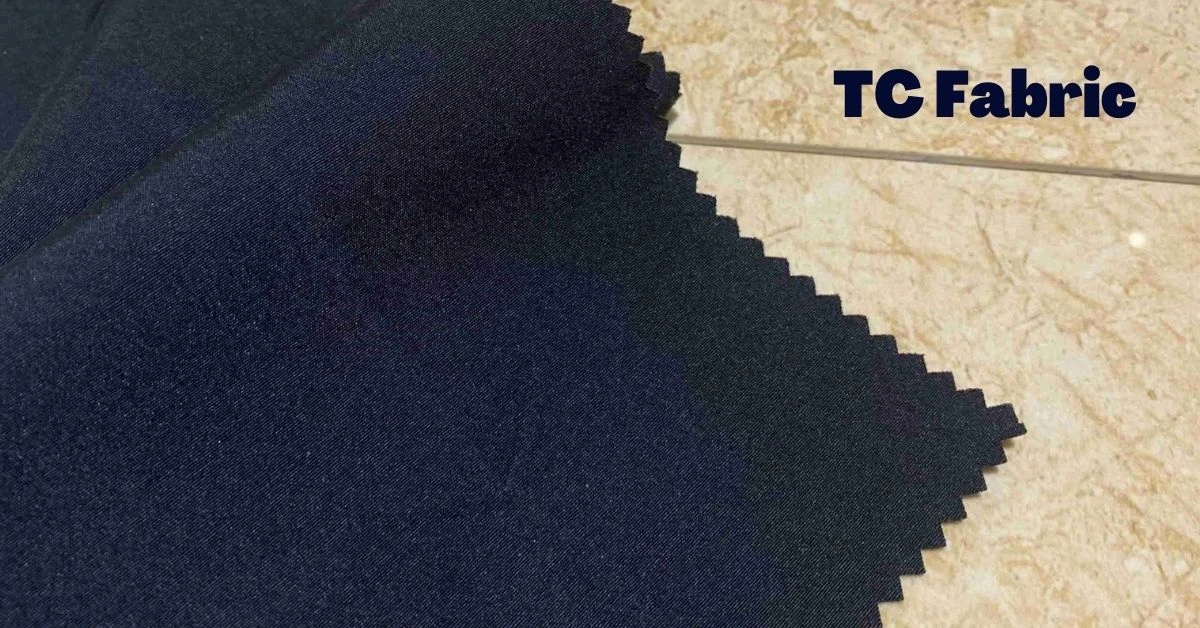

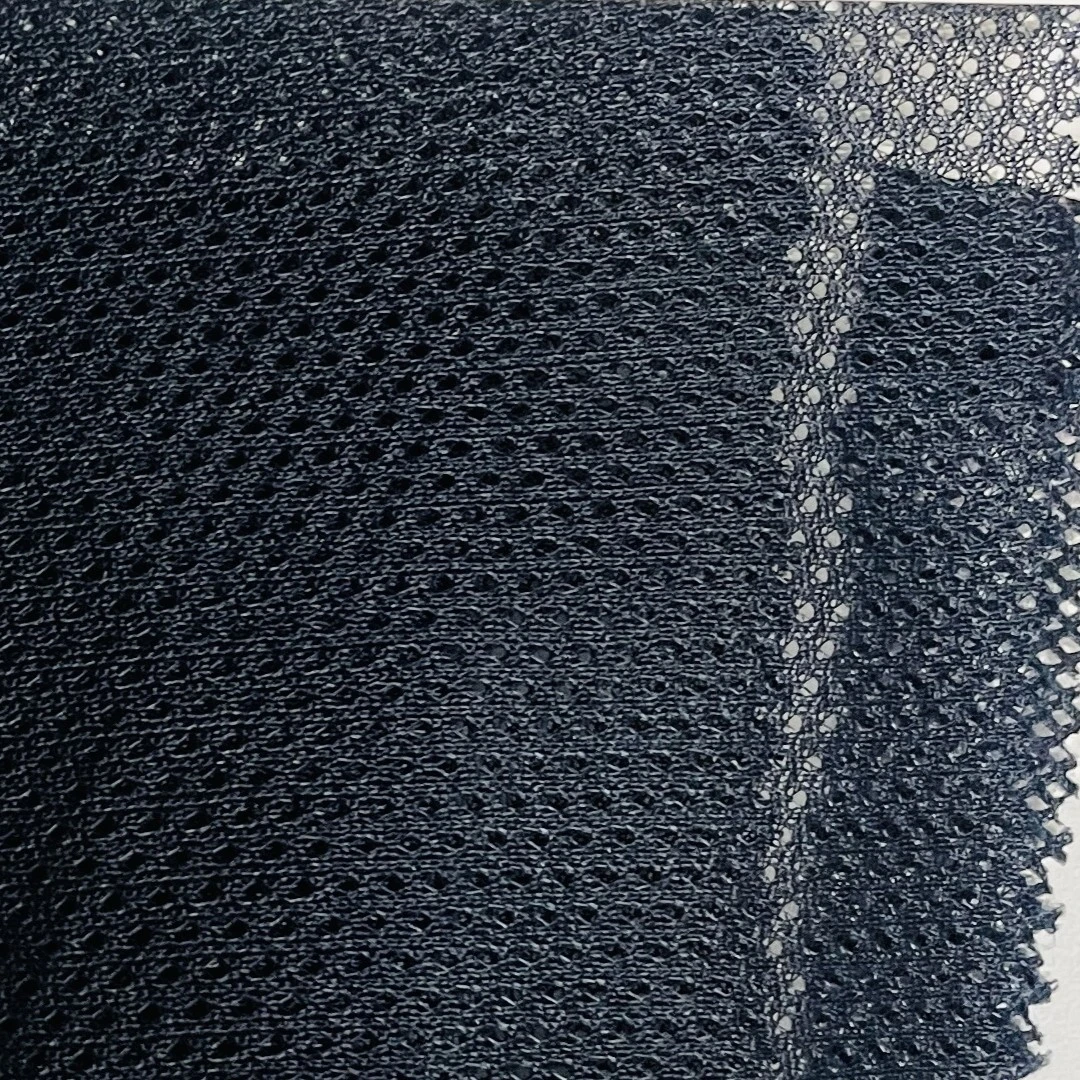

TC fabric refers to Tetron cotton fabric which is made from a combination of cotton and polyester. However, the amount of polyester yarn in this fabric is always relatively high compared to cotton, and the amount of polyester can be more than 50 percent.

TC fabric meaning: TC fabric, or Tetoron Cotton, is a fabric that is a blend of polyester and cotton. TC fabric is also known as "poly/cotton fabric".

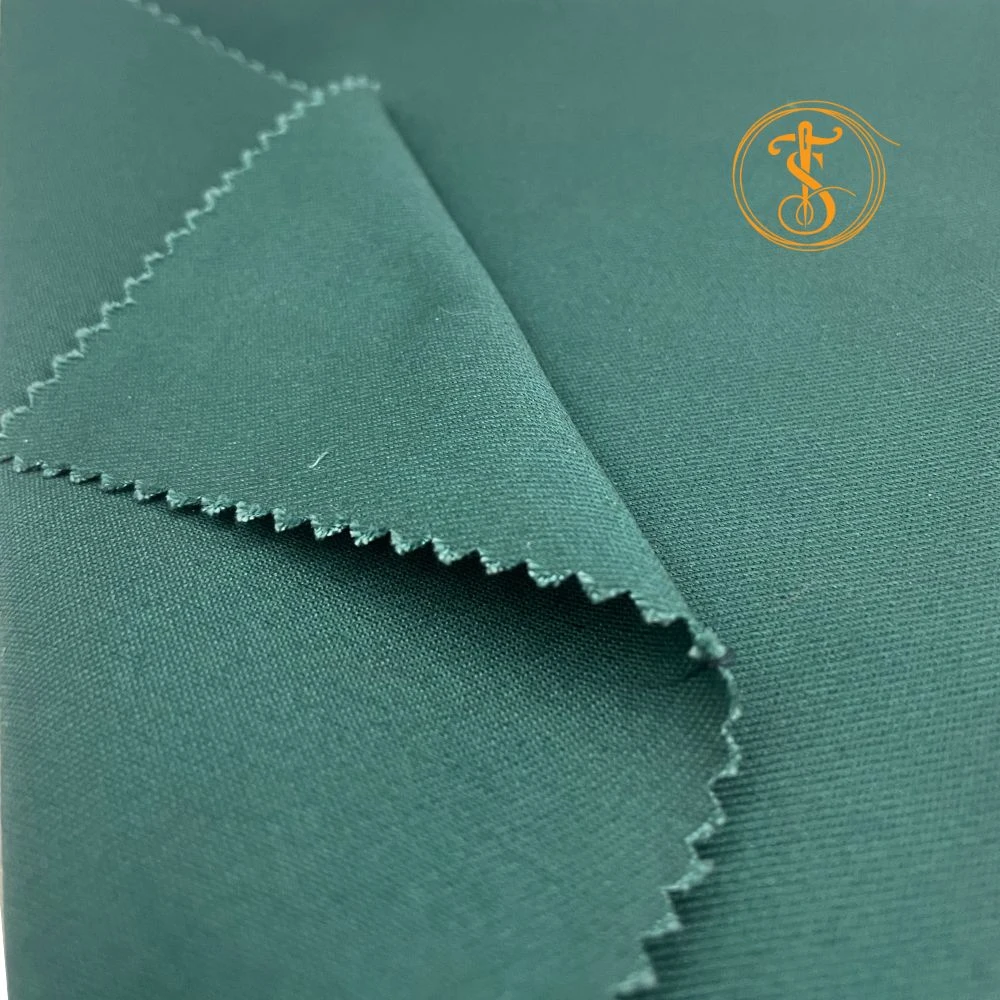

TC fabric is very popular because it offers excellent strength and durability, as well as a high level of colorfastness, which provides good hygienic properties. These fabrics don't quickly lose their form and are easy to care for. They are also or crease and breathable, hygroscopic, and long-lasting.

Types of TC Fabric

Different kinds of Tetron cotton fabric are available in the market. Some of the treading types are as:

- TC Twill

- TC Canvas

- TC Oxford

- TC Pocketing

- TC Lining

- TC Fleece

- TC Jersey

- TC Terry

Properties

|

Fabric |

Tetron-Cotton [TC] |

|

Compositions |

Cotton and Polyester |

|

Breathability |

High |

|

Heat retention abilities |

Medium |

|

Moisture-wicking abilities |

High |

|

Comfort Level |

Average |

|

Stretchability |

medium |

|

Prone to bubbling |

Low |

|

Durability |

High |

|

Washing temperatures |

Hot or Warm |

|

Commonly used in |

Workwear, Corporate clothing, uniforms, Furniture Covers, |

How is TC Fabric made?

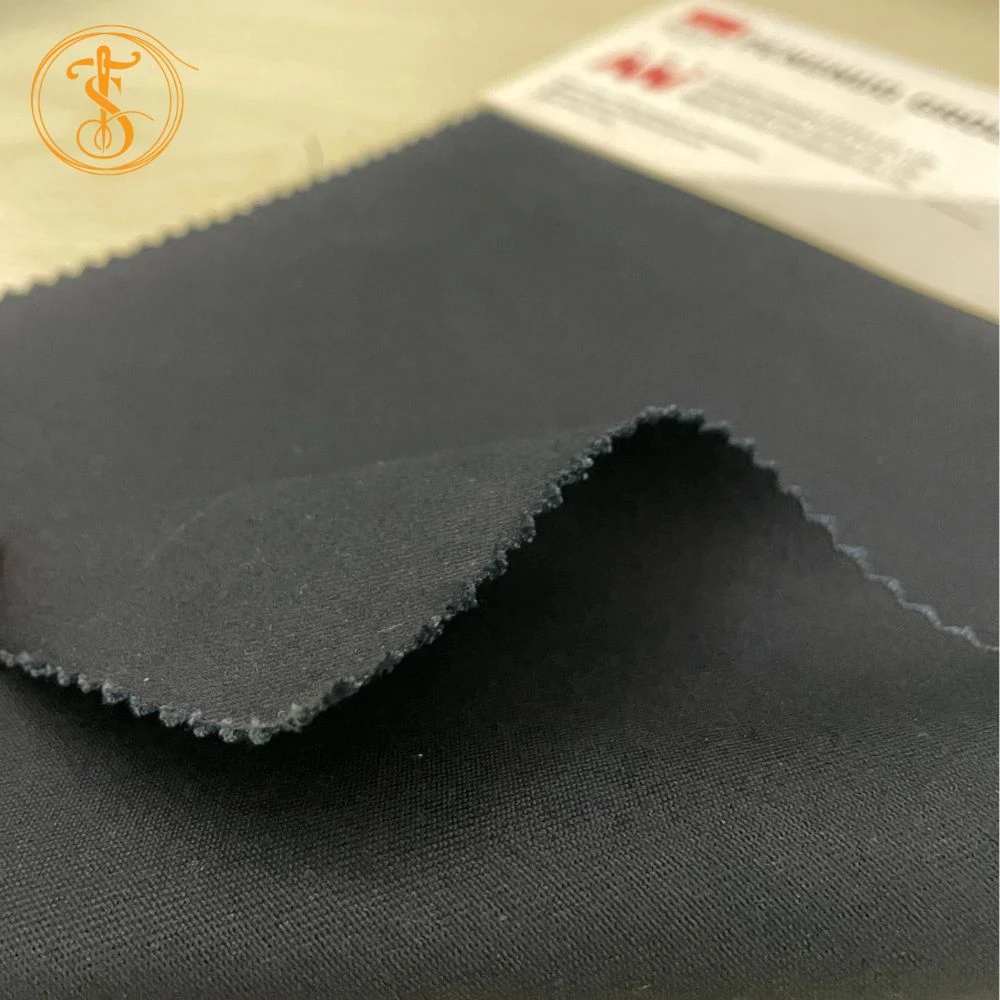

As the name suggests, TC fabric composition consists of 2 components, Tetron and Cotton. TC fabric is mainly made by blending cotton fiber or yarn with polyester. The blending process can be done in two ways as below.

- Fiber Blending

- Yarn Blending

However, the value of Tetron fabric or Polyester is always higher in this fabric by keeping a low ratio of cotton during the blending process. For example, the rate of Tetron or polyester for making TC fabric can be 60% -70% whereas cotton content can be 30% - 40%.

Dyeing Process of TC

The dyeing work of TC Fabric is a significant factor since polyester can be dissolved in water easily (hydrophobic character) whereas cotton is easily dissolved in water (hydrophilic character). Due to their two different dying characters, it’s inevitable to dye polyester and cotton with different classes of dyes and conditions. As the dying process of cotton and polyester is completely different, the dyeing method consists of two different parts as shortly explained below.

In the first part, the polyester portion is dyed mostly with dispersed dyes in one bath, and then the dispersed dye particles on the cotton portion are removed by a reduction-clearing process. After that cotton part is dyed with mostly reactive dyes in a separate bath. But nowadays single bath dyeing is getting popular since this method reduces dyes and auxiliary cost and process time, improving productivity.

Features

- TC Fabric is a very popular type of polyester cotton fabric used for a variety of corporate wear, workwear, and uniforms as well.

- TC fabric provides an optimal polyester and cotton ratio guaranteed with excellent strength properties and good hygienic properties.

- TC fabrics have very small shrinkage indicators and good colorlessness; they wash easily and show excellent breathability, hygroscopic and durable properties.

- TC fabric is the most popular for garments, especially available for purchase for price, durability, and more comprehensive color selection.

TC Fabric vs CVC Fabric

Tetron Cotton (TC) is a polyester/cotton hybrid. About 40 years earlier, Tetron was the Japanese word for polyester. Cotton is manufactured from natural fibers, while polyester is made from petrochemicals. The Centex TC comprises 65 percent polyester and 35 percent cotton, and it is more chemical in nature.

CVC stands for Chief Value Cotton, which is a cotton/polyester hybrid. CVC is made up of 60% cotton and 40% polyester, according to Centex. The manufacturer uses CVC 45, but only Centex operates CVC 42. The cloth is denser, and CVC is more common when you use CVC 42.

Applications

- Plain TC fabrics are most suitable for uniform shirts (school, army, police).

- TC Oxford is a hot favorite for making corporate identity Inform.

- TC twill and canvas are always preferable for making heavier workwear clothing.

- Lightweight TC fabric is widely used as pocketing and lining

- TC fleece and TC terry fabrics are commonly used in making winter fleece and terry jackets.

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.