|

Features |

Details |

|

Also Known As |

Velvet-like fabric, Plush fabric |

|

Manufacturing Process |

Knitting or weaving followed by brushing and shearing for a soft pile finish |

|

Appearance |

Soft, plush surface with a slight sheen |

|

GSM Range |

180-350 GSM |

|

Composition Range |

80-100% Polyester, 20-100% Cotton, or blends with Spandex |

|

Construction Range |

Single jersey knit, double knit, or warp knit |

|

Functionality |

TPU (optional), PU (optional), AC, W/R (water-resistant coating optional), PVC (rare) |

|

Thread Density Range |

190T-360T |

|

Count Variations |

20D-75D (depending on the application) |

|

Full Width |

57/58”, 59/60”, 71/73” |

|

Fabric Breathability |

Moderate |

|

Moisture-Wicking Abilities |

Low to moderate |

|

Heat Retention Abilities |

High (excellent insulation due to pile structure) |

|

Stretchability |

Moderate to high (if blended with spandex) |

|

Prone to Pilling/Bubbling |

Moderate (depends on fiber quality and usage) |

|

Country First Produced |

France (1840s) |

|

Biggest Exporter Country |

China (Export Quantity: Approx. 40% of global export, ~500,000 tons annually) |

|

Recommended Washing Temperatures |

Cold to warm water (30-40°C), gentle cycle |

|

Applications |

Apparel (tracksuits, dresses, costumes), upholstery, curtains, car interiors, plush toys |

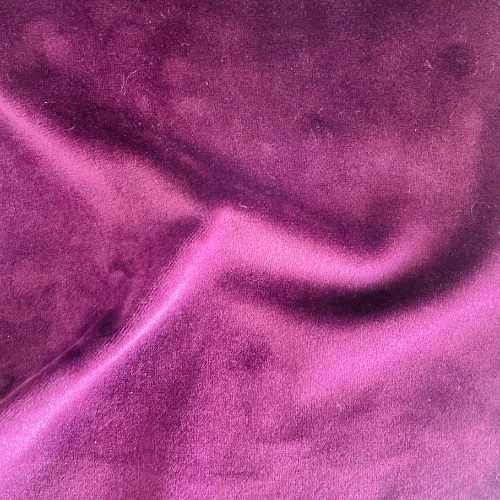

Velour is a knit fabric that is napped and has a cut pile texture. It may be created from a cotton mix or entirely from synthetic materials. This fabric is popular in the textile industry since it has several unique features. If you compare this fabric with velvet, it is more durable and luxurious than velvet fabric.

In the past, this fabric was used to manufacture different clothing applications. However, it is now primarily used in theater and other decorative applications. This article is going to discuss everything about this fantastic fabric. Continue reading this article to get a clear idea before starting a project with velour.

Table Of Contents

Velour Fabric

Velour is one of the popular fabrics in the textile industry, and this fabric has many similarities with velvet fabric. This fabric is an excellently soft as well as affordable fabric option. This knitted fabric is usually made from cotton. However, it can also be manufactured from synthetic materials. Velour is indeed a pile knitted fabric instead of a pile weaving fabric like velvet, making it easier to make and a little less opulent.

Velour fabric has an extended history in terms of fabric popularity. Velour became popular again in the fashion world in the 1990s and early 2000s when it was used for making clothes. As a fabric for clothing, velour has seen a considerable decline in popularity in recent years. However, their affordable price tag makes them popular once again.

While maintaining many of the coveted qualities of this opulent fabric, velvet is more resilient than velour. The soft, durable, and affordable features make this fabric useable for different textile applications. Velour is applied to use in a broad range of products, including apparel and furniture, amongst other things. The theater curtains are often made out of velour fabric.

What is Velour fabric made of?

Velour fabric is a widely used fabric in the textile industry. Despite having a luxurious appearance, velour is usually constructed of cotton; however, it may also be made of synthetic materials like polyester. Cutting crosswise looping threads using a unique weaving technique creates the "pile," a distinctively delicate pattern on the surface.

Knitted velour is indeed a terry fabric with natural flexibility that is typical of most knit fabrics. It has been combed and brushed. Velour that is woven has a cut pile and is stiff yet soft. Either kind of velour is often composed entirely of cotton.

Different types of Velour Fabrics

There are different types of velour fabrics available. Each and every type of velour fabric has several individual and exclusive features. Let's take a look at different types of velour fabrics.

Synthetic Velour

Synthetic velour is an inexpensive velour that is made of polyester. Sometimes mixed with spandex to increase stretchability. This kind of velour fabric comes with good enough softness and excellent texture.

Example: 95% Polyester 5% Spandex Velour Fabric

Stage curtains are a perfect use for synthetic fabric since it respond well to flame-retardant treatments. This velour fabric is used to manufacture different applications in the textile industry.

Cotton Velour

Up to the middle of the 19th century, cotton has been traditionally used to make velour. It gained popularity as a less expensive alternative to velvet since it was created from the same material. Cotton velour has only been utilized for upholstery and apparel after synthetic velour entered the market. As a stage curtain, it is no longer as common.

Velour Leather

Velour leather is created from animal skin. Like other forms of leather, velour leather is browned; however, producers employ chromium to produce this delicate leather design. Velour leather is renowned for being exceptionally soft to the touch and has a smooth, silky finish. Watch bands, shoes, coats, and upholstery are among the items most often made using velour leather.

Duvetyne

The two fabrics, duvetyne and velour, are very interchangeable. It is a cloth with a twill weave that resembles velvet and is frequently utilized by the theater industry for the production of stage curtains, as well as a theatrical cyclorama.

Velour vs Velvet: Key Differences

Velour and velvet are two popular fabrics in the textile industry that offer almost the same features and functionalities. However, some differences between these two fabrics set them apart from each other. Let's take a look at the key differences between Velour vs Velvet fabric.

- Customers who don't want to utilize synthetics or items from animals choose velvet. However, velour fabric costs are less costly than velvet or suede.

- Although it was created to seem like velvet, velour is really quite a distinctive fabric. Wool is used to making velvet, whilst cotton or polyester is used to make velour.

- On the other hand, Velour has a natural resistance to flame, in contrast to velvet, which does not. Velour is often preferred over velvet by those who work in the event sector because of this reason.

- Dresses and suits are the most typical garments made from velvet. Although you may use velour to manufacture dresses and sportswear, it is most often used to upholster curtains.

If you want to know deep about, about Velour vs Velvet, Click Here+

Velour Fabric Applications

Now it is the question, what is velour fabric used for, or what materials does produce from velour fabric. Velour fabric is one of the most popular fabrics in the textile industry. However, Over the last several decades, velour in clothing has drastically decreased. This fabric is now widely used in stage curtains.

Velour fabric is very well-known in the upholstery sector, particularly with regard to vintage and antique items. Although less widespread and popular, velour-made clothing, including sweaters, sportswear, jackets, skirts, and trousers, is also accessible in the garment sector. Velour has recently been utilized as a lining material for jewelry boxes.

Velour Fabric Care and Maintenance

The most effective method for maintaining velour is to wash it in normal water with other colors of the same kind. To prevent the nap from being ruined, it is best to lay this fabric out to dry rather than dry it in an electric dryer on the lowest setting. However, in rare situations, this fabric may be dried in a dryer. There are attachments for vacuum cleaners that may be used to clean velour upholstery.

You can get it cleaned properly if it becomes soiled or damaged. You may also choose to have your garments dry cleaned; however, this method has the potential to alter the napping of the fabric, which can make the garment seem odd and cause it to feel awkward to wear.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.