Ever struggled to button a shirt with one hand? Snap buttons were invented to save you from that tiny, everyday battle. Whether on denim jackets, baby clothes, or backpacks, these little fasteners quietly hold our outfits (and patience) together. But not all snaps are equal — especially when comparing plastic snap buttons with metal snap buttons.

Snap Buttons

A snap button (also called a press-stud or popper) is a two-part fastener that joins when pressed and releases when pulled apart. It’s like a mini magnet, but mechanical.

Each snap has two main parts — the socket (female part) and the stud (male part). When you press them, they click securely, producing that satisfying snap sound.

The first snap button was patented in 1885 by German inventor Heribert Bauer, designed mainly for men’s trousers. Since then, this small invention has evolved into a multi-material, multi-size marvel used across fashion, upholstery, and even military gear.

Table Of Contents

Types of Snap Buttons

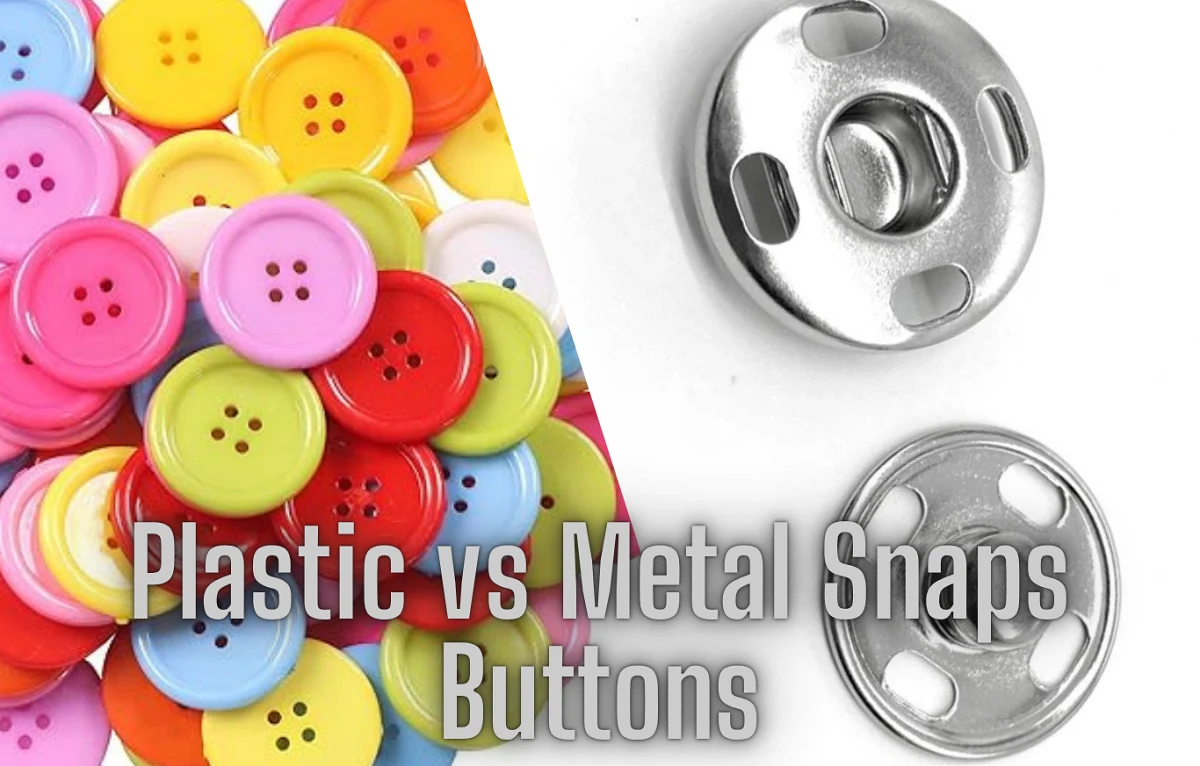

Not all snaps are born the same. Their material and structure decide how they perform, how long they last, and even how they look. Let’s compare the two main types: plastic and metal.

1. Plastic Snap Buttons

Plastic snap buttons are made fr om polyacetal resin (POM) or nylon, kn own for their light weight and flexibility. They’re common in babywear, raincoats, and home-sewing kits.

Advantages:

- Lightweight (around 60% lighter than metal snaps)

- Rust-proof and washable

- Safe for children’s clothing (no sharp edges)

- Available in 100+ colors

Disadvantages:

- Less durable under high stress

- Can crack under heat or UV exposure

- Not ideal for heavy fabrics like denim or canvas

To put numbers to it: a standard 12mm plastic snap can withstand 3–4 kgf of pull strength, while heavier garments often demand twice that.

2. Metal Snap Buttons

Metal snap buttons are made from brass, aluminum, stainless steel, or nickel-plated alloys. They dominate outerwear, jeans, leather goods, and industrial clothing due to their toughness and shine.

Advantages:

- Extremely durable (pull strength up to 10–12 kgf)

- Withstand washing, heat, and pressure

- Offer premium, polished appearance

- Long lifespan (often outlasts the garment)

Disadvantages:

- Can corrode if low-grade metal is used

- Heavier than plastic

- May cause fabric tear on delicate materials

If you’ve worn jeans, you’ve met a metal snap — it’s what keeps your denim from betraying you in public.

Key Differences between Plastic vs Metal Snap

|

Feature |

Plastic Snaps |

Metal Snaps |

|

Durability |

Moderate (3–4 kgf pull) |

High (8–12 kgf pull) |

|

Weight |

Light |

Heavy |

|

Rust Resistance |

Excellent |

Moderate |

|

Cost |

Low |

Medium to High |

|

Temperature Tolerance |

Up to 80°C |

Up to 300°C |

|

Best For |

Babywear, casual shirts, lightweight fabrics |

Jeans, jackets, bags, uniforms |

So, if you’re designing baby rompers or rain ponchos, go plastic. But if you’re crafting workwear or denim jackets, metal snaps are your MVPs.

Where Snap Buttons Are Used in the Textile Industry

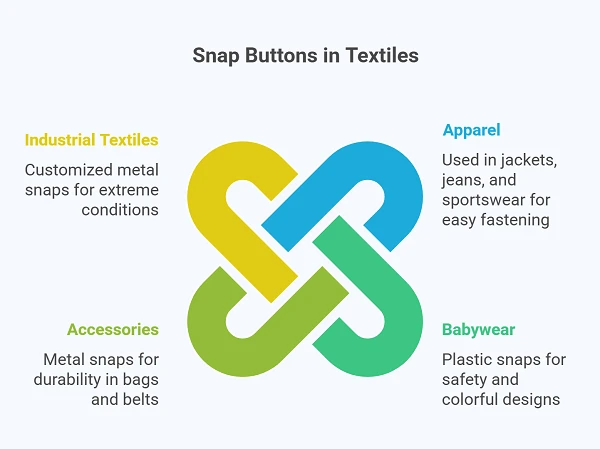

Snap buttons sneak into almost every corner of the garment world:

- Apparel: Jackets, jeans, polo shirts, and sportswear rely on metal or plastic snap buttons for easy fastening and long-lasting hold.

- Babywear: Plastic snaps dominate here — safe, smooth, and colorful.

- Accessories: Bags, caps, and belts often feature metal snaps for durability.

- Industrial Textiles: Fire-resistant and waterproof clothing use customized metal snaps for extreme conditions.

It’s fascinating — over 1.2 billion snap buttons are manufactured globally each year, according to textile market data (2024).

Choosing the Right Snap Button for Your Product

Picking a snap isn’t guesswork — it’s textile science.

Here’s how a garments technologist approaches it:

- Fabric Type: Heavy denim or canvas? Use metal. Light cotton or polyester? Go plastic.

- Functionality: Is it decorative or functional? Metal adds shine, while plastic blends in.

- Maintenance: Will it face washing, heat, or chemicals? Metal handles extremes better.

- Budget: Plastic saves up to 30% compared to metal in bulk orders.

- Design Intent: Choose colors that match the garment’s theme for a cohesive look.

Pro tip: Always test the snap’s holding strength on a fabric sample before production. A mismatched snap can ruin the garment’s life expectancy.

Final Thoughts

Plastic snap buttons win for lightness, safety, and budget. Metal snap buttons reign supreme for strength, style, and longevity. The right choice depends on your garment’s story — soft and playful, or rugged and bold.

Snap buttons may look tiny, but they hold the fashion world together — literally and metaphorically. Next time you hear that click, know that a whole world of engineering sits behind it.

FAQs

1. Are plastic snap buttons safe for baby clothes?

Yes. They’re smooth, non-toxic, and rust-free — perfect for sensitive baby garments.

2. Why do some metal snap buttons rust?

Rust forms on low-grade metals or poor plating. Always choose nickel-free or stainless options.

3. Can I replace a broken snap button at home?

Absolutely. With a hand press tool and the right snap size, you can fix it in minutes.

4. Are snap buttons better than regular buttons?

For speed and convenience, yes. But regular buttons still win in decorative applications.

5. How do I identify good-quality snaps?

Check for firm closure, smooth surface, and no sharp edges. High-quality snaps feel “tight,” not loose.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.