Table Of Contents

What is Stitching Thread?

Stitching thread is a continuous strand of fiber used to join pieces of fabric and create seams that hold a garment together. It is engineered for strength, elasticity, smoothness, and durability. Industrial machines run at 3,000–5,000 stitches per minute, which puts the thread under heat, friction, and mechanical stress. Though stitching thread accounts for only 1–1.5% of garment material cost, it influences nearly 80% of seam performance. If the thread fails, the garment fails. Simple as that. So even though it looks small and humble, stitching thread is the silent backbone of every outfit we wear.

Why Stitching Threads Matter in Garment Production?

If fabric is the body of a garment, stitching thread is its lifeline. Without the right thread, even the finest fabric can fall apart after one wash. About 80% of garment failures are linked to poor seam performance — often caused by the wrong thread choice. Sounds dramatic? Maybe. But anyone who’s seen a popped seam in a new shirt knows how real that pain is.

Let’s dive into the world of stitching threads used in garment manufacturing and uncover what makes them strong, flexible, and reliable.

Different Types of Stitching Threads

A) Based on Raw Material

1. Cotton Threads

Cotton threads come from natural fibers and are loved for their softness and matte finish. They work best on lightweight cotton fabrics like shirts or dresses. However, they’re not great for high-speed stitching due to their lower tensile strength (around 2.8–3.2 g/denier).

2. Polyester Threads

These are the workhorses of the garment world. With strength nearly 40% higher than cotton, polyester threads resist shrinking, fading, and wrinkling. Most denim and sportswear brands rely heavily on core-spun polyester threads for durability and flexibility.

3. Nylon Threads

Nylon threads have high elasticity — up to 25% elongation — which makes them perfect for stretch garments, lingerie, and swimwear. They’re smooth and glossy, offering excellent abrasion resistance.

4. Silk Threads

Luxury deserves luxury. Silk threads, though expensive, provide unmatched smoothness and sheen. They are commonly used in high-end garments, bridal wear, and embroidery.

5. Linen Threads

Strong, natural, and slightly rough linen threads are perfect for heavy-duty stitching, especially in upholstery and leather goods. Their tensile strength is around 5.5 g/denier, which explains their popularity in heavy garments.

B) Based on Construction

1. Spun Threads

Made by twisting short fibers, spun threads have a soft touch and are ideal for cotton fabrics. They tend to have higher friction, making them easy to control during stitching.

2. Core-Spun Threads

These threads feature a polyester filament core wrapped with cotton or polyester fibers. The result? A balance between strength and a soft surface feel — perfect for jeans, trousers, and knitwear.

3. Filament Threads

Filament threads are continuous fibers with high strength and shine. They are used in automotive upholstery, footwear, and industrial garments.

4. Textured Threads

Textured threads have a fluffy appearance and high elasticity. They’re commonly used in overlock and coverstitch seams to provide stretch and softness against the skin.

C) Common Types of Stitching Threads Used in Garment Manufacturing

1. Polyester-Cotton Thread

A mix of 65% polyester and 35% cotton, this thread blends the durability of polyester with the natural touch of cotton. It’s widely used in school uniforms, shirts, and casual wear.

2. Core-Spun Polyester Thread

Arguably, the most popular in garment factories worldwide. With a tenacity of 4.5 g/denier, this thread runs smoothly through high-speed machines without breaking. Ideal for denim, outerwear, and woven garments.

3. Nylon Monofilament Thread

This clear, single-filament thread disappears into fabric seams, making it a favorite for invisible stitching in lingerie, lace, and transparent fabrics.

4. Kevlar Thread

Used where strength is non-negotiable — think firefighter uniforms or bulletproof vests. Kevlar threads can handle temperatures up to 425°C and are five times stronger than steel of the same weight.

5. Metallic Thread

More about style than strength. These decorative threads add sparkle and are used for embroidery, trims, and embellishments in fashion garments.

How to Choose the Right Stitching Thread?

Thread Strength and Tensile Properties

Thread strength should match the fabric’s tensile properties. For example, a 60 GSM cotton fabric pairs well with a 60s count thread, while denim (300 GSM) may need a 20s core-spun polyester thread.

Seam Performance and Fabric Compatibility

A thread must pass the seam slippage and seam puckering tests. Poor compatibility leads to uneven stitches and visible puckers, especially on delicate fabrics.

Colorfastness and Shrink Resistance

Always look for threads that resist fading in ISO 105-C06 washing tests. Polyester and nylon outperform cotton in maintaining color and shape after multiple washes.

Industry Statistics and Facts

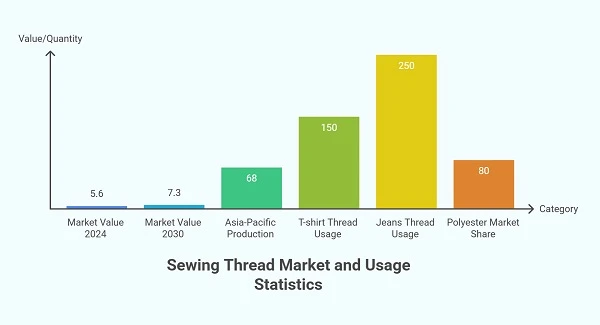

- The global sewing thread market was valued at USD 5.6 billion in 2024, projected to reach USD 7.3 billion by 2030.

- Asia-Pacific accounts for nearly 68% of the total production, with China, India, and Bangladesh leading.

- An average T-shirt requires about 150 meters of stitching thread, while a pair of jeans uses nearly 250 meters.

- Polyester-based threads dominate with over 80% market share due to their cost-effectiveness and high-speed performance.

Final Thoughts

Threads rarely get the spotlight, but they hold every stitch of creativity together. From cotton comfort to Kevlar toughness, the types of stitching threads used in garment manufacturing define not just durability but the soul of every piece we wear. The next time you see a neatly finished seam, remember — the real hero is the thread you don’t notice.

FAQs

1. What is the strongest thread used in garment manufacturing?

Kevlar thread is the strongest, with tensile strength five times higher than steel of the same diameter.

2. Which thread is best for high-speed sewing machines?

Core-spun polyester threads are ideal due to their smooth surface and consistent strength.

3. Why do some threads break during sewing?

Common causes include poor-quality thread, wrong needle size, or excessive machine tension.

4. Are cotton threads suitable for synthetic fabrics?

Not really. Cotton threads lack elasticity and can break on stretchable or synthetic fabrics.

5. How can I test thread quality?

Perform a tensile strength test and a colorfastness check under washing or ironing conditions to ensure reliability.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.