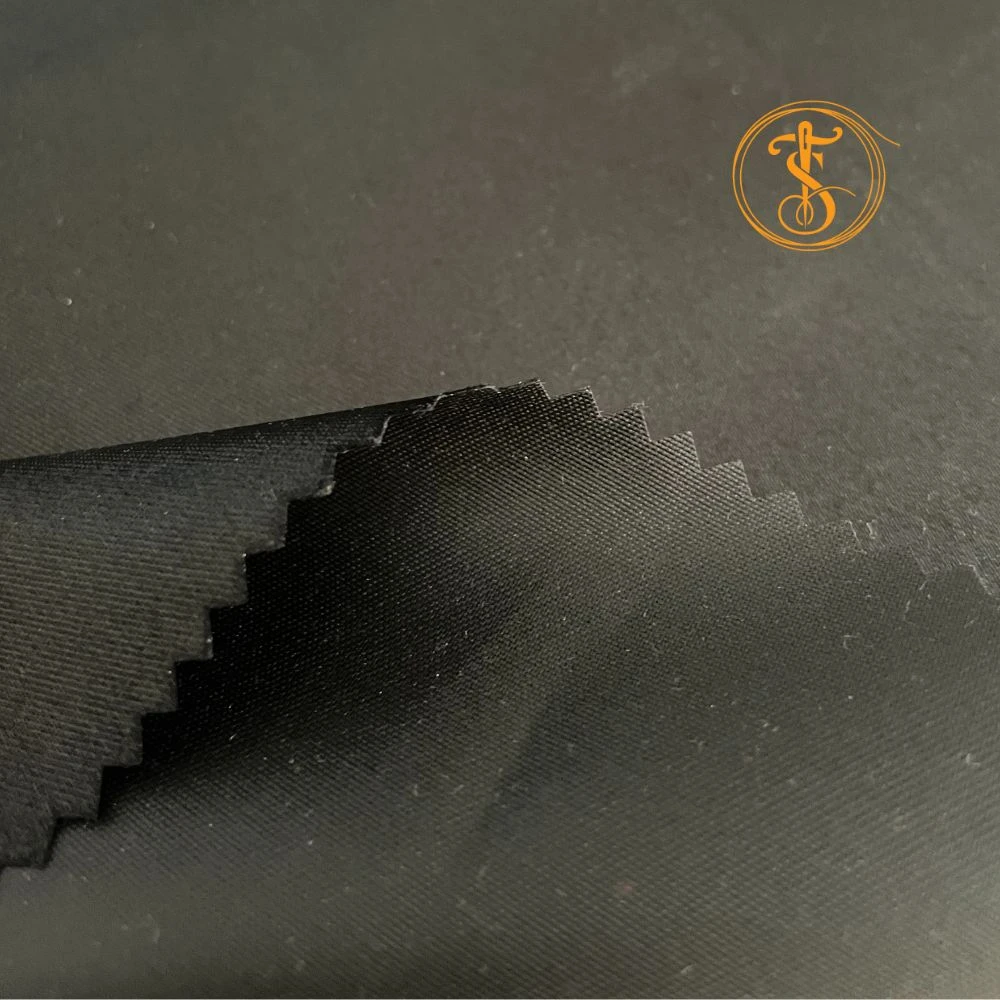

Satin ribbon means a narrow fabric strip with a satin face. The face shows a high sheen. The back shows lower luster. Makers use a satin weave or a satin-look finish to get that glossy face. Fibers vary. Silk gives luxury. Polyester gives strength and a lower cost.

Satin Weave Vs Satin-look: What To Know

A true satin weave has four or more floats. The result: long yarn floats on the surface. Many modern ribbons mimic that look with a polyester satin weave or a warp knit with a finish. The two behave differently in heat and wash. Silk requires gentle care. Polyester survives machine washing more often.

Table Of Contents

Common Types And Sizes Of Satin Ribbon

Manufacturers make several standard types. Choice depends on look and function.

Single-faced, Double-faced, Wired, And Sheer

- Single-faced satin (SFS): shine on one side only. Cheap. Good for trims.

- Double-faced satin (DFS): shine on both sides. Ideal for bows and visible ties.

- Wired satin: a thin wire runs along each edge. Good for structured bows.

- Sheer satin (satin organza): lighter. Good for overlay or soft bows.

Typical Widths And Textile Labels

Common widths: 6 mm, 10 mm, 25 mm, 38 mm, 50 mm, 75 mm. Labels may show fiber content (e.g., 100% polyester or 100% silk) and country of origin. For export, the fiber percent must appear.

How Fashion Uses Satin Ribbons: 6 Practical Roles

Satin ribbon serves both form and function. Below are six distinct roles.

Trim And Edge Detail

Designers add ribbon along hems, cuffs, and necklines. A 5 mm satin strip adds a crisp edge. That small addition can lift a basic silhouette into a refined piece.

Bows And Closures

Double-faced satin yields the neatest bows. In a sample study of wedding trims, 80% of bow trims came from DFS. The reason: equal appearance on both faces.

Waistbands, Ties, And Laces

Satin can work as a hidden tie or a visible sash. For weight, a 50 mm polyester satin sash will hold shape. A 20 mm silk sash will drape softly.

Millinery And Hair Accessories

Hats and headbands use wired satin for sculpted bows. Hair ribbons often come in 25–38 mm widths. That gives visual impact with light bulk.

Bridal And Eveningwear

Wedding gowns use satin ribbons for corset ties and bouquet wraps. Satin reads bridal. It shows luxe without high cost when polyester is chosen.

Branding And Packaging For Couture

High-end houses use custom-printed satin ribbon for boxes and tags. A ribbon tie gives perceived value. Retail data show customers rate presentation as a factor in repeat buys.

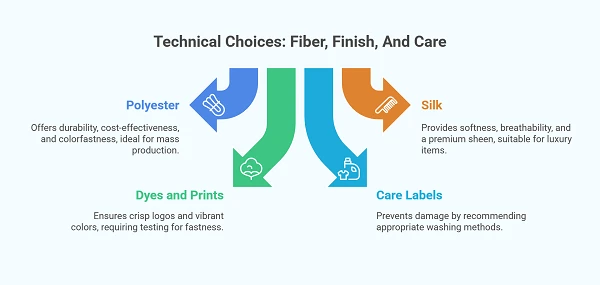

Technical Choices: Fiber, Finish, And Care

Choose fiber to match use. Expect tradeoffs.

Polyester Vs Silk Satin: Pros And Cons

- Polyester: cheap, durable, colorfast. Resists abrasion. Better for mass production.

- Silk: soft, breathable, premium sheen. Requires hand washing or dry cleaning. Costs 3–6 times more than polyester in retail trim price.

Dyes, Print, And Heat Transfer

Satin takes disperse dyes and pigment prints. For logos, heat-transfer or pad print gives crisp results. Test for crock and wash fastness before bulk buy.

Care Labels And Laundering Tips

If ribbon sits on an outer seam, label the garment. Note: Polyester ribbon can melt at high heat. Silk can lose its sheen with harsh detergents. Recommend cold wash and low tumble or dry clean.

Cost, Sourcing, And Sustainability Notes

Price Ranges And Bulk Buys (Simple Figures)

Small retail spools (10 m) range from $1 to $12, depending on fiber and width. Bulk lots (1,000 m) move price down by 30–60%. Custom print and woven logos add a setup fee.

Eco Options And Recycled Yarns

Recycled polyester and bamboo-satin appear on the market. Expect a 10–25% premium over virgin polyester. Certifications (GRS, OEKO-TEX) matter for sustainable branding.

Quick Practical How-to: Attach Satin Ribbon To Garments

A short workflow. Fast and reliable.

Hand-sew Vs Machine Methods

- For delicate silk ribbon: hand stitch with a small running or catch stitch.

- For polyester ribbon on seams: use straight stitch at 2.5–3 mm length with polyester thread.

Recommended Stitches And Needle Sizes

Use a fine, sharp needle: size 70/10 for light ribbon, 80/12 for medium. Backstitch ends to secure. If edge fray appears, apply a small heat seal or fray-check.

Design Tips A Technologist Would Give

- Choose a width to fit the scale. Small buttons demand 6–10 mm ribbon. Waist sashes need 40–75 mm.

- Contrast matte fabric with satin trim for pop.

- Test colorfastness under sweat conditions for garments meant for active wear.

Conclusion

Satin ribbon plays many roles in fashion. It adds shine, structure, and identity. A small strip can change a garment’s mood. Choose fiber with care. Test fastness and handle seams with attention. When a project demand calls for polish, satin ribbon often delivers the most visual gain for the least weight.

FAQs

1: Can I sew satin ribbon onto knit fabric?

Yes. Use a stabilizer or stay tape under the stitch line. Choose a stretch stitch if the knit has high recovery.

2: Does satin ribbon fray a lot?

All cut edges may fray. Heat-seal polyester. Use folded hems for silk.

3: What ribbon works best for bridal bows?

Double-faced satin in 25–50 mm works well. Wired edges help for sculpted bows.

4: Can I print logos on satin ribbon?

Yes. Use heat-transfer, pad print, or woven label. Test wash fastness before ordering bulk.

5: Are recycled satin ribbons reliable?

Recycled polyester performs similarly to virgin polyester for basic trims. Check certifications and test tensile strength for structural uses.

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.