Let's break this down without the fluff. 450D Oxford fabric is a mid-weight woven fabric made using a 450 denier yarn. The “D” stands for denier, which measures the yarn’s thickness. The higher the number, the stronger and heavier the fabric. This fabric sits comfortably between the lighter 300D and the heavier 600D versions. It balances durability, weight, and flexibility—ideal for products needing decent strength without feeling like armor.

|

Parameter |

Details |

|

Also Known As |

Midweight Oxford, 450 Denier Oxford, 450D Polyester/Nylon Fabric |

|

Manufacturing Process |

Woven using a plain or basket weave. Finished with coating (PU, PVC, TPU) for enhanced functionality |

|

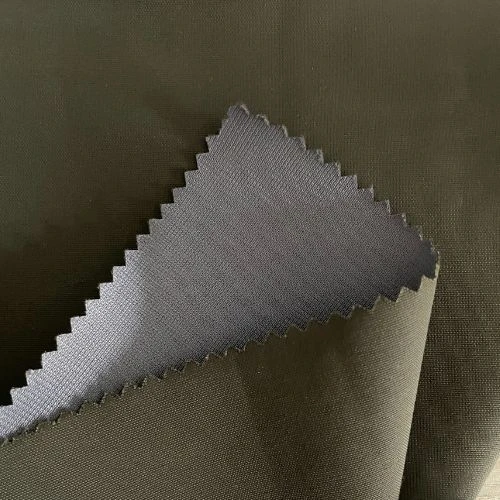

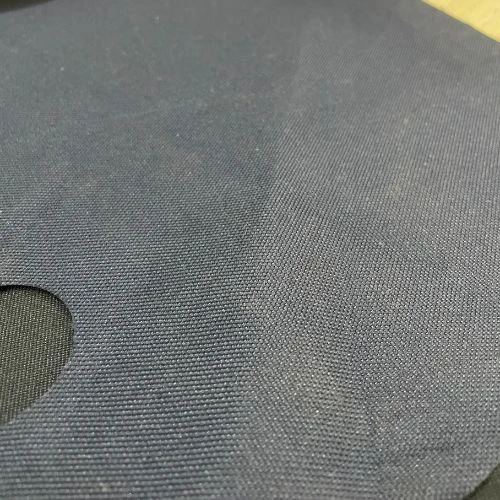

Appearance |

Matte or semi-glossy. Tightly woven surface with visible weave texture |

|

GSM Range |

150 – 250 GSM |

|

Composition Range |

100% Polyester, 100% Nylon, or blended (e.g., 90% Polyester / 10% Cotton) |

|

Construction Range |

450D x 450D or 450D x 300D depending on backing. 6–12 threads per cm (warp) |

|

Functionality Coatings |

PU (Polyurethane), PVC (Polyvinyl Chloride), TPU (Thermoplastic Polyurethane), AC (Acrylic), W/R (Water Repellent), PV (Polyvinyl) |

|

Possible Yarn Count |

450 Denier (approx. 1.35 Tex); filament or spun yarns |

|

Full Width Options |

57/58”, 59/60”, 71/73” |

|

Fabric Breathability |

Moderate (varies by coating type: PU > PVC in breathability) |

|

Stretchability |

Non-stretch unless mechanically or chemically treated; optional mechanical stretch in warp or weft |

|

Prone to Pilling/Bubbling |

Low pilling (if uncoated); minimal bubbling if coating is applied evenly and cured properly |

|

Country First Produced (with Year) |

United Kingdom (early 1900s for traditional Oxford; coated variants emerged in Asia in the 1980s) |

|

Biggest Exporter Country |

China (Exports over 230,000 metric tons/year of Oxford fabrics, including 450D variants) |

|

Recommended Washing Temperatures |

Hand wash or machine wash at max 30°C; avoid hot water for coated versions |

|

Finishing Uses to Increase Functionality |

- Anti-UV treatment - Antimicrobial coating - Flame retardant finish - Anti-static - Teflon water/oil repellent coating |

|

Abrasion Resistance |

Medium to High (12,000–20,000 rubs on Martindale scale, depending on finish) |

|

Tear Strength |

15–20 N (warp), 12–18 N (weft) |

|

Tensile Strength |

180–220 N (warp), 150–190 N (weft) |

|

Colorfastness |

3–4 (uncoated), 4–5 (coated) under ISO 105 standards |

|

UV Resistance (with PU coating) |

85% – 95% UV blockage depending on coating thickness |

|

Mildew/Mold Resistance |

Moderate to High (especially with anti-fungal treatment or PVC backing) |

|

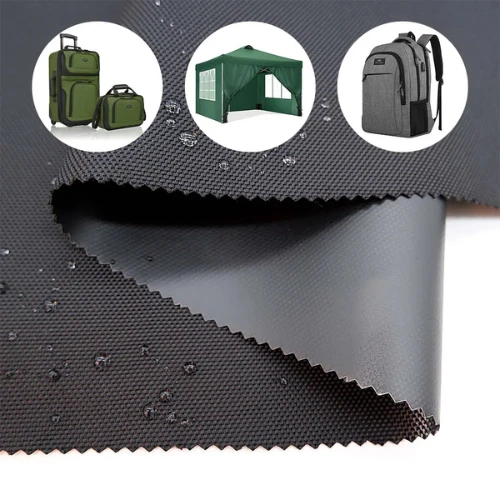

Applications |

Backpacks, Tactical bags, Tents, Canopies, Duffel bags, Military gear, Jackets, Outdoor Furniture Covers, Car seat covers, Umbrellas |

|

Sustainability Notes |

TPU coatings are eco-friendlier than PVC; Recycled polyester (rPET) options are now available for 450D grades |

|

Common Defects to Inspect |

Coating bubbles, color shading, uneven GSM, slubs, skewing |

|

Common Blends |

Polyester + Cotton (Oxford Chambray), Polyester + Spandex (for minimal stretch), Nylon + PU (for durability) |

|

Standard Roll Lengths |

50–100 meters/roll, depending on the manufacturer |

Oxford fabric itself is known for its basket-weave construction, originally used in dress shirts. Over time, it evolved into a versatile utility fabric used in bags, jackets, and tents.

Table Of Contents

Composition and Manufacturing Process

450D Oxford fabric is typically made from polyester or nylon. Both have their perks, but polyester tends to be more UV resistant, while nylon performs better in tear resistance.

It uses a plain or basket weave, and to make it more functional, manufacturers add coatings:

- PU (Polyurethane): Light, flexible, and water-resistant.

- PVC (Polyvinyl Chloride): Heavier but better water resistance.

- TPU (Thermoplastic Polyurethane): High-performance, eco-friendlier option.

Depending on the use case, the coating can boost the fabric’s waterproofing, UV protection, and even flame resistance.

Key Features

Durability and Strength

450D Oxford fabric offers moderate strength, perfect for everyday outdoor products. For context, it can withstand a tensile strength of around 180–220 N (newtons), which is strong enough to carry a loaded backpack or survive windy days in a tent form.

Its abrasion resistance makes it great for areas that see frequent rubbing or contact, like shoulder straps or tent corners.

Water and UV Resistance

When coated with PU, 450D Oxford fabric can resist 1000 mm to 3000 mm water pressure. That’s enough to keep your gear dry in moderate rain.

UV resistance depends on the fiber and coating. Polyester blends with PU coating can block over 90% of UV rays, ideal for outdoor use.

Flexibility and Weight

450D fabric generally falls in the 150–250 GSM (grams per square meter) range. It’s light enough for portability but strong enough to handle rough conditions.

Need something foldable yet durable? 450D is a sweet spot.

Applications

Bags and Backpacks

This fabric shines in mid-range backpacks and tactical bags. It’s strong, light, and holds structure well without adding bulk.

Tents and Outdoor Covers

450D Oxford with PU or PVC coatings is used in tent floors, awning roofs, and motorcycle covers. It resists water, UV, and dust—all must-haves for outdoor gear.

Jackets and Uniforms

Though not for high-fashion, it's common in safety jackets, utility uniforms, and raincoats—where function matters more than flair.

Advantages and Disadvantages

Advantages

- Balanced strength-to-weight ratio

- Compatible with PU, PVC, TPU coatings

- Resistant to abrasion and moisture

- Versatile across outdoor and industrial applications

- More affordable than high-denier options

Disadvantages

- Not as rugged as 600D or 1000D

- Lower insulation value

- Needs coating for waterproofing

- Nylon versions may degrade faster under UV

How to Choose 450D Oxford for Your Project

Comparing 300D vs 450D vs 600D

|

Feature |

300D |

450D |

600D |

|

Weight |

Lightest |

Medium |

Heavier |

|

Durability |

Moderate |

Good |

Very Good |

|

Best For |

Lining, pouches |

Backpacks, covers |

Heavy-duty bags |

If you're making something like a tent cover or daily-use backpack, 450D hits the sweet spot.

Coating Considerations: PU vs PVC

- PU: Lightweight, flexible, better for wearables.

- PVC: Stronger water barrier but adds stiffness.

- TPU: Premium feel, better cold resistance, eco-friendlier.

Choose the coating based on weather, use, and eco goals.

Care and Maintenance Tips

- Washing: Hand wash with mild soap. Avoid harsh chemicals.

- Drying: Air dry. Don’t toss it in a dryer.

- Storage: Fold or roll. Avoid direct sunlight for long-term storage.

- Re-coating: Reapply PU spray if water beads stop forming.

With care, 450D Oxford fabric items can last 3–5 years under regular use.

Conclusion

450D Oxford fabric bridges the gap between lightweight materials and rugged durability. Whether you're designing backpacks, covers, or jackets, this mid-range option offers performance without the weight penalty. It’s the kind of fabric that works hard without complaining—just like you on a Monday morning.

FAQs

1. Is 450D Oxford fabric waterproof?

Yes, but only when coated—typically with PU or PVC. Uncoated versions are water-resistant but not waterproof.

2. Can 450D Oxford fabric be used for heavy-duty applications?

For most mid-weight tasks like backpacks or covers, yes. But for extreme load-bearing or abrasion, 600D Oxford Fabric or 1000D Oxford Fabric is better.

3. What’s the difference between 450D nylon and 450D polyester Oxford?

Nylon is more tear-resistant. Polyester offers better UV resistance and is more cost-effective.

4. Is 450D Oxford good for winter use?

With TPU coating, yes. It handles cold better and keeps moisture out. Just don’t expect thermal insulation.

5. How do I know if my 450D Oxford product is coated?

Look for water beading on the surface. You can also feel the inner layer—PU and PVC coatings feel smooth and slightly rubbery.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.