Ever owned a backpack that feels like it could survive an apocalypse? The odds are that it was made from 900D Oxford fabric. The “900D” refers to the denier count, a unit that measures fiber thickness. The higher the number, the tougher the fabric.

|

Parameter |

Specification / Details |

|

Also Known As |

Heavy-Duty Oxford, 900 Denier Oxford, Tactical Oxford Fabric |

|

Manufacturing Process |

Warp and weft weaving using basket or plain weave + chemical coating (PU, PVC, TPU, etc.) |

|

Appearance |

Matte or semi-gloss finish, depending on coating; visible weave texture; stiff hand feel |

|

GSM Range |

350–450 GSM |

|

Composition Range |

100% Polyester (most common), or Nylon/Polyester blends (e.g., 80/20) |

|

Construction Range |

900D x 900D plain weave or basket weave; 10–16 ends/inch (warp), 10–14 picks/inch (weft) |

|

Functionality |

TPU (high-end), PU (standard), PVC (rigid), AC (anti-condensation), W/R (water-resistant), PV (UV-resistant) |

|

Possible Yarn Count |

900D/1 (denier count single yarn), Tex 100–110 |

|

Full Width Options |

57/58”, 59/60”, 71/73” usable widths depending on coating and use |

|

Fabric Breathability |

Low (especially with PVC/TPU coatings); moderate with PU coating only |

|

Stretchability |

Minimal (woven construction); mechanical stretch is near zero |

|

Prone to Pilling/Bubbling |

No (due to high denier and strong coating stability) |

|

Country First Produced (Year) |

United States, around the 1960s (as a development of military-grade synthetic fabrics) |

|

Biggest Exporter Country |

China (approx. 1.2 billion meters/year, mostly from Zhejiang and Jiangsu regions) |

|

Recommended Washing Temperatures |

Max 30°C (PU-coated), Max 40°C (PVC-coated), Hand wash or spot clean recommended |

|

Finishing Uses to Increase Functionality |

Anti-UV, Anti-fungal, Flame-retardant, Mildew-resistant, PU double-coating, Teflon coating, Silver/Reflective back |

|

Weather Resistance |

High (with PU or TPU), UV-resistant, mildew-resistant (with chemical treatment) |

|

Abrasion Resistance (Martindale Test) |

30,000–50,000+ cycles (depending on coating and weave tightness) |

|

Tear Strength |

Warp: 220–300 N / Weft: 180–270 N (typical range) |

|

Tensile Strength |

Warp: 2000–3000 N / Weft: 1800–2700 N |

|

Colorfastness to Light |

4–5 (out of 5) with UV-resistant finishing |

|

Coating Adhesion Strength |

PU: 2–3 N/cm, PVC: 3–5 N/cm |

|

Environmental Concerns |

PVC is less eco-friendly (contains chlorine); TPU & PU are more eco-conscious alternatives |

|

Applications |

Tactical backpacks, luggage, awnings, tents, ATV covers, outdoor cushions, tool bags, tarps, seat covers |

|

Cost per Yard (Estimated) |

$2.00 – $4.00 USD (based on coating and supplier origin) |

|

MOQ (Common from suppliers) |

500–1000 meters (can vary by supplier) |

|

Customization Options |

Digital printing, reflective logo printing, lamination, foam bonding, embossing |

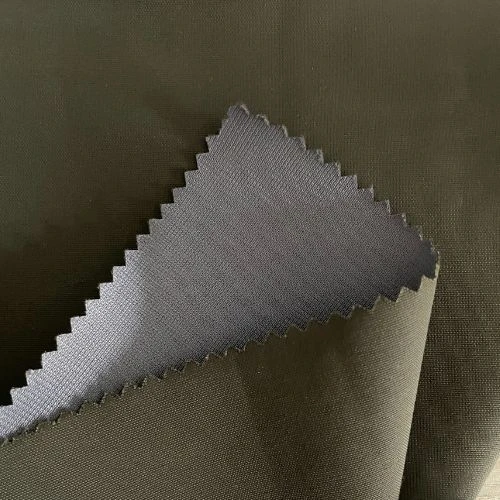

Oxford fabric, in general, is a woven synthetic textile—usually polyester or nylon—known for its durability and slight sheen. The 900D version? It's a beast. Stronger, heavier, and more water-resistant than most lower-denier Oxfords, this fabric is built to withstand wear, tear, and the wrath of the outdoors.

Table Of Contents

Key Characteristics of 900D Oxford Fabric

Durability and Strength

This fabric doesn’t just play tough—it is tough. With a tensile strength of around 2100–3000 N (depending on coating and weave), 900D Oxford can handle high-pressure use without fraying or tearing. It's perfect for rugged environments where other fabrics would cry for mercy.

Water Resistance and Coatings

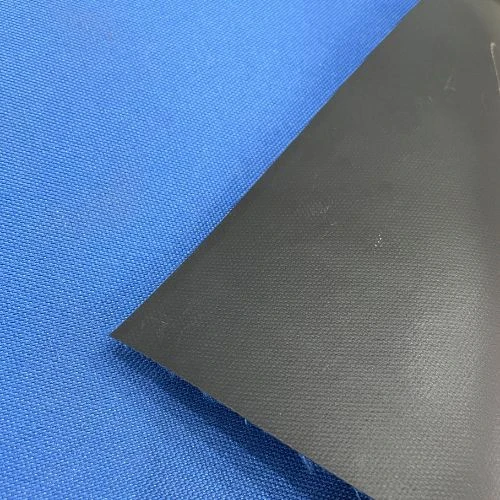

Raw polyester alone isn't waterproof, but coat it with PU (polyurethane), PVC, or TPU, and you'll get serious protection.

- PU coating is flexible and cost-effective.

- PVC offers stiffer water resistance but adds weight.

- TPU gives top-tier water resistance and breathability—ideal for high-end gear.

Some versions of 900D Oxford even achieve 5000 mm+ waterproof ratings, making them great for rain covers, tents, or outdoor furniture.

Weight and Thickness

- GSM (grams per square meter) for 900D Oxford fabric ranges between 350–450 GSM, depending on coating and finishing.

- This puts it firmly in the heavyweight class, without being so thick that it’s hard to work with.

Common Applications of 900D Oxford Fabric

Outdoor Gear and Equipment

Think camping chairs, awnings, and ATV covers. The fabric stands up to UV rays, moisture, mud, and mildew. Nature throws punches—900D punches back.

Bags, Backpacks, and Luggage

Most tactical backpacks and high-end duffels use 900D. Why? It resists abrasion, holds structure, and doesn’t tear easily. It’s the go-to for military, hiking, and heavy-duty urban gear.

Industrial and Commercial Use

From tool bags to industrial aprons and even cargo covers, 900D Oxford is trusted in environments where lightweight materials would get shredded.

How is 900D Oxford Fabric Made?

Denier Rating Explained

“900D” stands for 900 denier, meaning each thread weighs 900 grams per 9,000 meters. For reference, 600D Oxford Fabric is lighter and more flexible, while 1000D is bulkier and stiffer. The 900D hits the sweet spot—durable without being overly heavy.

Coating Types (PU, PVC, TPU)

These coatings seal the weave, improve water resistance, and enhance appearance. PU is soft and flexible. PVC is thick, rubbery, and rugged. TPU, the priciest option, offers elasticity, strength, and eco-friendliness.

900D Oxford vs. Other Oxford Fabrics

|

Fabric Type |

Strength |

Weight (GSM) |

Coating Compatibility |

Common Use |

|

210D |

Light |

~100–150 |

PU/TPU |

Linings, covers |

|

300D |

Medium |

~160–210 |

PU |

School bags, fashion items |

|

600D |

Heavy |

~220–300 |

PU/PVC |

Backpacks, cases |

|

900D |

Strong |

~350–450 |

PU/PVC/TPU |

Tactical gear, outdoor use |

|

1000D |

Strongest |

~450–600 |

PVC/TPU |

Military, high-end outdoor |

Pros and Cons of 900D Oxford Fabric

Pros:

- Highly durable and tear-resistant

- Excellent water resistance (with proper coating)

- Strong structure retention

- Versatile for outdoor, industrial, and travel use

Cons:

- Heavier than lower-denier options

- Less breathable

- PVC coating can crack in extreme cold

Care and Maintenance Tips

- Wipe with a damp cloth; no bleach or harsh detergents

- Air dry—avoid machine drying or direct sun exposure for long periods

- Avoid sharp tools or blades near coated surfaces

- Reapply waterproof spray after heavy use to maintain the coating

Final Thoughts: Is 900D Oxford Fabric Right for You?

If you're someone who wants a fabric that can survive drops, drags, storms, and scrapes, 900D Oxford fabric is your best bet. It might not be light and airy, but it’s got your back when the going gets tough. Whether you’re trekking through a jungle, packing heavy gear, or just need a cover that won’t give out, this material delivers strength with style.

FAQs About 900D Oxford Fabric

Q1: Is 900D Oxford fabric waterproof?

Not by itself, but with a PU, PVC, or TPU coating, it becomes highly water-resistant or even waterproof.

Q2: Can I sew 900D Oxford with a regular machine?

Yes, but use a heavy-duty needle and polyester thread. A walking foot helps, too.

Q3: How thick is 900D Oxford compared to canvas?

It’s thinner than canvas but more abrasion-resistant. Think tough and smooth, not stiff and scratchy.

Q4: Is 900D better than 600D?

Yes, in terms of strength and durability. But it’s also heavier, so consider your needs.

Q5: What’s the best coating for 900D Oxford?

If you need flexibility—PU. For rugged waterproofing—PVC. For breathability and eco-friendliness, TPU.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.