DTG printing represents the future of apparel customization! This cutting-edge technology prints bright, high-resolution graphics straight into clothes, making every detail stand out.

DTG printing meets your specific requirements, from one-of-a-kind masterpieces to small batches. It's the ideal choice for expressing your creativity on personalized garments because it's fast, eco-friendly, and has a beautiful soft feel.

Table Of Contents

What is DTG Printing?

DTG, known as, direct to garment printing, refers to the method of printing in which graphics and images are directly inject-printed on the surface of the fabric without using any intermediary screen or paper. It uses a special digital printer to directly apply water-based inks to the garment surface. When you touch the design you do not feel the ink as it goes straight into the fiber of the fabric.

Usually, using DTG printing, it is easy to transfer graphics and impacts onto fabrics. This method also comes in great use for decorating higher garment value. It requires less floor space. Even, the learning curve is pretty steep for the DTG method. It does not require making, cleaning, or storing screens on multiple settings.

DTG Printing History

DTG printing brings a paradigm shift in the customized apparel sector. The first appearance of DTG can be traced back to the late 1990s. The first time, DTG printing attempts to print full-color images. The image then directly transfers onto textiles. Before DTG printing, screen printing was in great demand.

It still is but in limited edition, because of the traditional approach and time-consuming methods. DTG printing has high costs and technological limitations for the initial setup procedure. Even if there are drawbacks, DTG has been a potential method for both innovators and risk-takers. DTG printing is a practical, scalable, and groundbreaking technique for upcoming years.

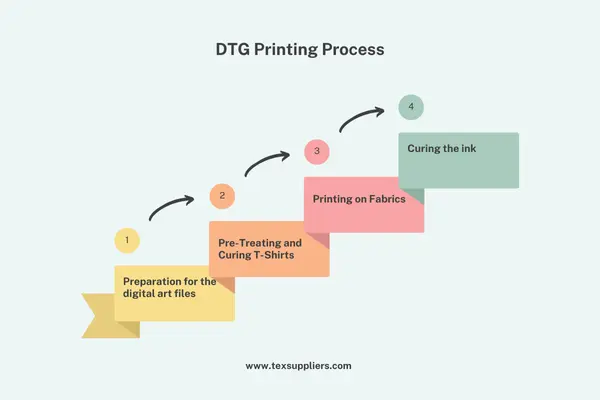

DTG Printing Process

DTG printing works in a couple of ways. Here is the entire procedure:

Requirements:

-

Print water-based inks

-

Digital art files

-

Fabric

Step-by-step process:

-

Step 1: Preparation for the digital art files: DTG serves the best on the PSG and PNG format graphics. It applies inks using the pattern based on the digital file. Photoshop software uses RGB (Red, Green, and Blue) color modes. Meanwhile, DTG uses models on the CMYB color modes. CMYB means, Cyan, Magenta, Yellow, and Black. So, if the file is in RGB mode, with the use of Raster Imaging Processor software, the file can be easily transferred to CMYK files.

-

Step 2: Pre-Treating and Curing T-Shirts: DTG printers work best with natural fibers. Natural fibers include cotton, hemp, and bamboo. The pre-treatment machine applies the solution of liquid to keep the white ink from soaking into the fabric. After this application, it is easy to cure with a heat press to make the fabric printing surface flatter.

-

Step 3: Printing on Fabrics: After pretreatment, place the fabric on a flat platform called a platen for printing. This base stabilizes the cloth, keeping it flat and aligned for ink application. Align the fabric by matching the neckline, shoulder seams, and side seams. After aligning the cloth, feed it into the printer to start the printing process.

-

Step 4: Curing the ink: After printing the fabric, it is critical to cure the ink so that it adheres well to the garment and remains durable after multiple washings. This method employs a heat press or forced air drier.

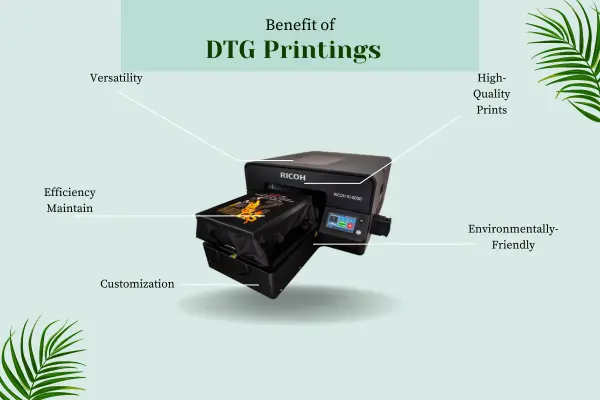

Benefits of DTG Printings

DTG printing helps in many ways due to the revolutionizing technology to custom apparel. Not only does it boost creativity but also DTG helps anyone to make an informed decision to avail the unique advantage. The benefits of DTG printing are below:

-

Versatility: DTG printing is suitable for cotton fabric only. But it works fine on light and dark-colored apparel. It provides flexibility to choose from a wide range of customized products. It is easy to incorporate any number of colors into the designs without any additional costs.

-

High-Quality Prints: DTG printing offers intricate designs. It provides detailed images to be printed onto the garments. The result of high-quality print is that it is vibrant and high-resolution.

-

Efficiency Maintain: DTG printing is optimal for orders that are low-volume in terms of quantity. Besides, it applies to one-offs as well. This efficiency makes the printing method an ideal tool for start-ups and business owners to check. DTG printing does not require an initial setup similar to screen printing. So, it provides quick results.

-

Environmentally-Friendly: DTG uses water-based ink technology. It is an eco-friendly method that produces less waste. Besides, it does not require screens for each color.

-

Customization: DTG printing uses full-color customization. It allows any business to create unique designs based on individual customers and specific events. That is why, customization is appealing for businesses in the industries of fashion mostly.

Conclusion

DTG printing has been a game-changer in the apparel industry. It is one of the newest arrival technologies for customization. DTG Printing uses apparel printing technology to ensure quality, and efficiency in the industry. DTG provides a cost-efficient way of production and customization of apparel.

Among its wide-ranging benefits, DTG printing handles multiple colors, image resolution, and photographic images. Overall, DTG is the factor that includes the production process with quality printing with zero to minimal environmental impact.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.