Looking for more stability in fabric areas? If yes, you should look at “Interlining”, the essential garment element. Well, interlining is an extra fabric that has an addition to a garment. There is a need to provide more warmth in a winter fabric or a lighter-weight fabric. Interlining, applied by sewing and bonding, is a well-constructed lining from the actual garment. Sometimes, finishing becomes a necessary instrument to improve the properties. Looking out for what is interlining in details available in the textile industry in this article.

Table Of Contents

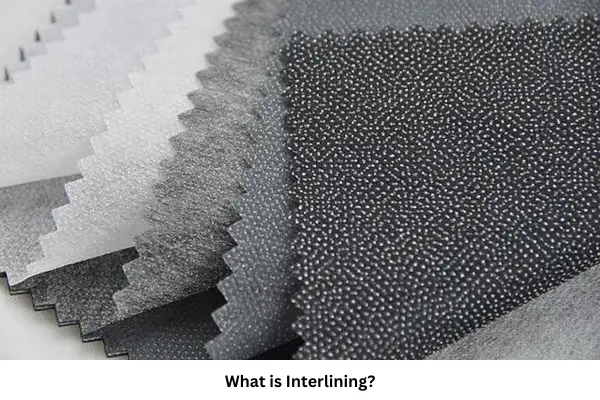

What is Interlining?

Interlining refers to the supporting fabric used between the two layers. This interlining or supporting fabric gets attached to garments through the sewing process or alternative methods.

Objective of Interlining

The actual purpose of this interlining is to retain, control, and support specific areas of garments. Also, there is a need to keep the real shape. Several interlinings are removable. They separate from a specific garment and attach to the finished garment. Interlining has a criterion of getting used in heavy or rigid fabrics.

That is why, for interlining, we always support canvas and non-woven fabrics.

Types of Interlining

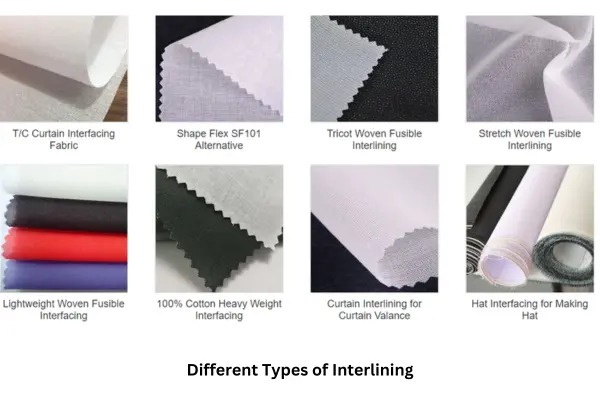

Selecting a suitable interlining type is difficult. To help decide the interlining type, one must evaluate hid needs, material condition, and care instruction. There are distinct types of layering methods, for instance, Spun and wet-laid, linear laying, and cross-laid. Other bonding methods are chemical with binders and mechanical with needles.

Interlinings have classification into diverse types. These are:

1. Based on Fabric Structure:

a. Woven Interlining

Woven interlining is there to support coats and cloaks. The fabric material is 100% cotton which makes the fabric stiff. There is an application of starch and non-fusible interlinings. The biggest advantages are strength and stability. The woven has plain weaves. The disadvantages are that the woven interlining is expensive for casual garments.

b. Non-Woven Interlining

There is no involvement of yarn in making the fabric. This interlining happens from the fiber to fabric stage. The non-woven interlining lacks strength for apparel use. However versatility and flexible application are the best techniques for this interlining.

c. Knitting Interlining

Knitting interlining has variations to impart flexibility and stability. The interlining is lightweight and has a soft hand feel. The use is to find bulked filaments. The interlining is expensive in nature, and the application area is fashionable outfits.

2. Based on application point:

- Fusible

- Non-Fusible or Sewn Interlining

Description of the Interlinings on based one application point:

a. Fusible Interlining:

This interlining gets used between different layers of fabrics by sewing. For that reason, it knows as sewn interlining. There is a requirement for heat and pressure. This interlining is the most used one for any apparel type. Fusible interlining is a usable area of a “ready to wear” garment. Fusible interlining has both advantages and disadvantages. These are:

Advantages of Fusible Interlining:

- Availability is higher

- Easy to apply process

- Higher productivity

- Less fusing time

- Budget-Friendly

Disadvantages of Fusible Interlining:

- The requirement of High temperature

- The need for exceptional care

Fusible Interlining Types:

Fusible interlining is available in the following types based on the resin coating and its properties. They are:

Polyethylene coated

It is used in a resin coating. The resin coating provides a greater resistance ability.

Polyamide coated

Polyamides are widely used in cleanable garments. The temperature remains at 60 degrees Celsius.

PVC coated

Poly Polyvinyl chloride is resin-coated and suitable for cleanable garments.

Polyester coated

Polyester-coated interlining is usable in any type of garment. It is an ideal and available garment with a high price.

Polypropylene coated

The resin is polyethylene coated. The fabric is an “attached” thing to the interlining process.

PVA coated

Poly Vinyl Acetate is a resin coating use thing with limited washability.

b. Non-Fusible Interlining:

There is no such difference from the fusible interlining. Just a bit different is, this interlining has a use between the two layers of fabric without any heat and pressure. To get better preparation for this non-fusible interlining, fabrics must have treated with starch. Then, it must get dry and then sewn with the main fabric. This interlining is available to use in the “Flame Retardant” apparel.

Advantages of Non-Fusible Interlining

- Making flame-retardant garments

- Easy techniques

- No elaboration on the machine

- Using in the steel industry

Disadvantages of Non-Fusible Interlining

- Not a better quality

- Not a suitable thing for large production

- Availability is low

- Heavy workload

- Labor cost is high.

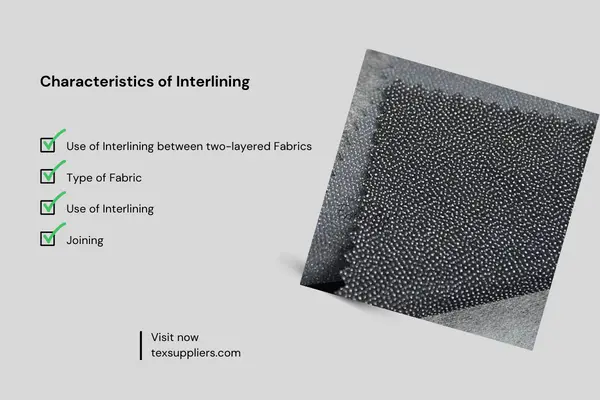

Characteristics of Interlining

Interlining is a bit different from the usual lining terms. Here are some characteristics mentioned below:

Use of Interlining between Two-layered Fabrics

Interlining is an accessory that can be usable between the fabric’s two layers.

Type of Fabric

The fabrics are made of cotton, polyester, nylon, viscose, and wool in interlining. Also, fabric types like canvas, flannel, and non-woven fabric can use interlining.

Use of Interlining

The use of interlining is in the collar, cuffs, jacket’s front part, and in coats. Interlining is also there to support the control area of the garments as well as to hold the actual shape.

Joining

Interlining gets joined by fusing and sewing.

Functions and The Application of Interlining

Functions and interlining application areas are quite different. Let us introduce you to the following functions and uses of interlining in the following section.

Functions of the Interlining:

- Supporting the garment.

- Controlling the garment shape.

- Controlling the apparel area.

- Reinforcing the garment’s components

- Making the apparel attractive.

- Ensuring an anticipated quality of the fabric.

- Improving garment performance.

The Application Areas of Interlining:

Interlinings are available for use in collars, waistbands, cuffs, front facing, outwear, blazers, jackets, plackets, etc. Interlining is nothing but a lining between the pre-existed lining and the fabric outside part in a sewing manner. Mostly, dressmakers add the interlinings to the neckline areas and the front parts of the coats. Interlining does not have any notices as it remains inside the garment.

Advantages of Interlining

The advantages of interlining have several numbers. Hear them out in the following part:

- Cannot be seen from the outside

- Maintaining the structure of the garment.

- Making the garment stiffer.

- Remaining in the outer fabric.

- Made from Non-Woven fabrics.

- Better dry cleanability

- Perfect for garment dyeing

- Easy fusing with hard ire.

- Comparatively low stream reaction.

Disadvantages of Interlining

- Steam fusing capability is absent

- There is no such high-frequency fusing capability

- Hardening of the fabric handle

- Taflon belts’ contamination.

Conclusion

We have already guessed that what is interlining, is a textile layer used between fabric layers. It imparts strength and stability to the outer part of the fabric. For instance, men’s shirts use fusible interlining in collar areas to hold the stiffness. While becoming fused to the fabric’s outer shell, interlining acts as a composite. It improves the fused part’s longevity. Interlinings can be a disadvantageous mechanism if fabric requires flexibility and the feel of a soft hand.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.