Spacer fabric has just entered into the innovative foam-coated fabric replacement with a 3-dimensional structure. The unique properties of the spacer ensure breathability, insulation, and properties of moisture-wicking. From cushions to other automotive textiles, spacer remains an ideal concern for use in wound care. The even distribution weight makes the fabric a comfortable choice.

Table Of Contents

What is Spacer Fabric?

Spacer fabric refers to the three-dimensional knitted sandwich fabric. It consists of two different knitted substrates. These remain in a compact version together. Sometimes, these substrates keep themselves apart by spacer yarns. The spacer is suitable to use for protective gear and bags.

The three-dimensional structured fabric is now an emerging field. Its features offer extensive conditions with varied applications.

What is Spacer Fabric made of?

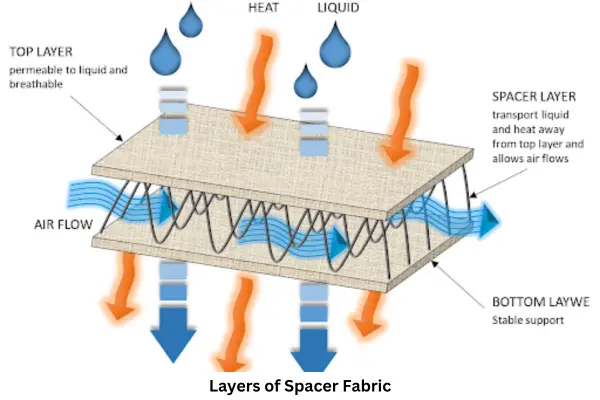

Spacer fabric is made of polyester, kevlar, polyamide, and microfiber. There are three layers in this fabric. The first layer refers to the hydrophilic nature, whereas, the second layer refers to the hygroscopic nature. The spacer layer is mono and multi-filament based.

Here is the table of Layers:

|

First Layer: Hydrophilic Nature Second Layer: Hygroscopic Nature Third Layer: Mono or Multi Filament |

Spacer fabric accelerates the discharge. The discharge of body heat, sweat, and moisture through the effect named siphoning, diffusion, and transmission. Air flows in the middle to form a cooling-like situation. It achieves dryness, cooling, heat conduction, and other comforting effects.

Spacer Fabric Manufacturing Process

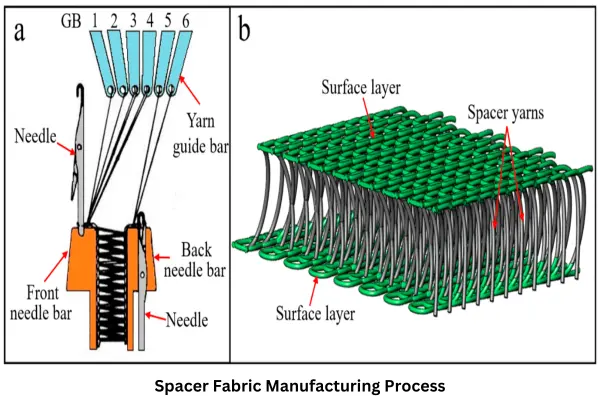

Spacer fabric follows circular knitting where the thickness is woven from 1mm to 5mm. It is breathable, 4-way stretch, and heat-insulating fabric. There are three dimensions, comprising an initial layer, an interior layer, and a third outer layer. The third layer of spacer’s mono-filaments can be polyester, polyamide, or polypropylene.

Besides, these fabrics are well-designed for airflow and cushioning. The ventilation provides the cool air. It also allows temperature control and maximum air circulation. The three-dimensional fabric is produced through technologies like knitting and weaving.

Properties of Spacer Fabric

|

Fabric Name |

Spacer, or Sandwich fabric |

|

Fabric Compression Elasticity |

Excellent |

|

Breathability |

Good |

|

Air Permeability |

Good |

|

Cushioning |

Good |

|

Fabric Vapor-Transport |

Adjustable |

|

Fanroc Height Preset |

Very between 1.5 to 5.5 mm |

Types of Spacer Fabric

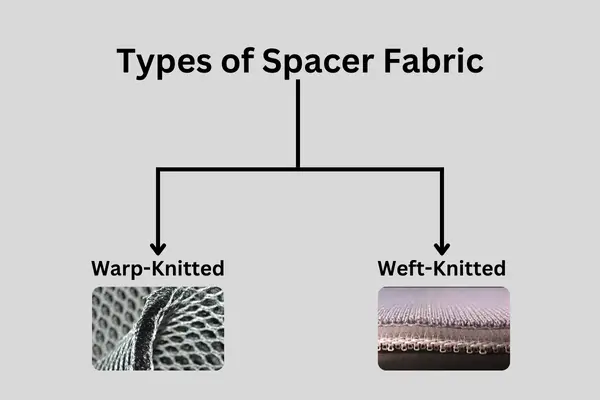

Spacer fabric has two types. They are: Warp-Knitted and Weft-Knitted.

-

Warp-Knitted: The Spacer is knitted on the rib raschel machine. It has two needle bars. It consists of two ground surfaces. These are bound through the pile yarns using stitches.

-

Weft-Knitted: Spacer gets knitted on a double jersey circular machine. It has a rotatable needle cylinder. It also has a needle dial. A circular knitting machine allows two-needle sets with the ability to create two individual layers. Weft knitted is produced using flat, purl, and v-bed machines.

Spacer Fabric Applications

The use of Spacer fabric is almost everywhere! It is there in tennis shoes, car seat cushions, backpacks, and other areas. The fabric allows the natural ventilation properties. It is perfect to use every day. The spacer has a soft, cushiony nature that ensures higher breathability.

-

Accessories: Cycle Helmets, Composites, Boot Soles, Medical Products, Firefighters’ Clothing, Seating, Body Armour, automobile, locomotive seat covers, and hard hat liners.

-

Upholstery: Bedding furniture, mattresses, cushions, sofas, and pads.

FAQs:

-

Why is Spacer Fabric called Sandwich Fabric?

Spacer fabric has a three-dimensional spacer structure. This structure works like a sandwich. The construction of this fabric consists of two separate fabric webs. These webs remained joined together by Spacer threads.

Conclusion

Spacer fabric is breathable, cushioned, and overall a multi-faceted fabric. Most application of this fabric goes to the practical making of a variety of products. It uses a microfilament yarn between two fabrics. Besides, the fabric creates a breathable microclimate between the layers. These layers make heat and vapor the way to pass through easily.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.