In the era of nanotechnology, we notice the word microfiber everywhere from furniture to sportswear. But what is microfibre fabric, exactly? What makes microfiber fabric so versatile? Let’s have a look at all the details about microfiber.

Table Of Contents

What is microfiber fabric?

The word micro indicates Micron, whereas nanotechnology refers to 10−6, a micrometer. And Microfibre means extremely thin synthetic fiber. A microfibre must be finer than a denier of yarn to be exact. The fabric made with microfiber is popular as a microfiber fabric. There are several types of microfiber in the market, such as nylon, polyester, Kevlar, and so on. However, conventional microfiber is composed of polyester and polyamide.

|

Properties |

Details |

|

Fabric Name |

Microfiber Fabric |

|

Fabric Also Known As |

Micro denier Fabric, Microfiber Textile |

|

GSM Range |

80 - 250 GSM |

|

Composition Range |

80% - 100% Polyester, 0% - 20% Nylon or Polyamide |

|

Construction Range |

|

|

Possible Thread Count Variations |

180 - 800 threads per square inch |

|

Full Width |

57/58” or 59/60” |

|

Cuttable Width |

57” - 59” |

|

Fabric Breathability |

Moderate |

|

Additional Coating Variations |

Water-resistant, Anti-static, Anti-microbial |

|

Moisture-Wicking Abilities |

High |

|

Heat Retention Abilities |

Moderate to High |

|

Stretchability |

Low to Moderate (depends on blend) |

|

Prone to Pilling/Bubbling |

Moderate (especially with frequent washing) |

|

Country Where Fabric Was First Produced |

Japan |

|

Biggest Exporting Country Today |

China |

|

Recommended Washing Temperatures |

Cold to Warm (30°C - 40°C / 86°F - 104°F) |

|

Common Applications |

Swimming Shorts, Activewear, Cleaning cloths, Upholstery, Linings, Towels, Bedding |

Brief History

World scientists began experimenting in the 1950s with ultra-fine fibers, and then the production of this microfiber fabric actually began. In the late 1970s, microfiber fabric came to lead in textile applications, and it continued expanding until 1990. After 1990, several companies commercially developed microfiber to make easy-care fabrics for consumers. Since then, acceptance of the microfiber fabric has increased over the decades. Now, microfiber fabric is one of the largest segments of the multi-billion-dollar apparel industry.

Types of microfiber fabric:

There are different types of microfiber fabric made for various applications. Here are some of the most popular microfiber fabrics.

|

Weaving |

Composition |

Filament (F) |

Yarn Size (Denier) |

Thread Count (Warp × Weft) |

Weight (GSM) |

|

PLAIN |

100% Polyester |

144F |

75D × 150D |

148 × 76 |

95 |

|

PLAIN |

100% Polyester |

144F |

75D × 150D |

148 × 80 |

100 |

|

PLAIN |

100% Polyester |

288F |

75D × 150D |

148 × 83 |

105 |

|

TWILL |

100% Polyester |

144F |

75D × 150D |

148 × 88 |

110 |

|

TWILL |

100% Polyester |

144F |

75D × 150D |

148 × 100 |

120 |

|

TWILL |

100% Polyester |

144F |

75D × 150D/2 |

148 × 98 |

145 |

|

TWILL |

100% Polyester |

288F |

75D × 200D |

148 × 100 |

135 |

|

TWILL |

100% Polyester |

288F |

75D × 150D |

148 × 78 |

95 |

|

TWILL |

100% Polyester |

288F |

75D × 150D |

148 × 98 |

120 |

|

TWILL |

100% Polyester |

144F |

75D × 150D |

226 × 100 |

150 |

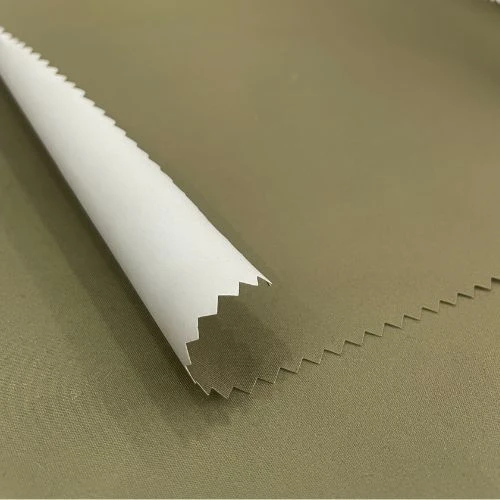

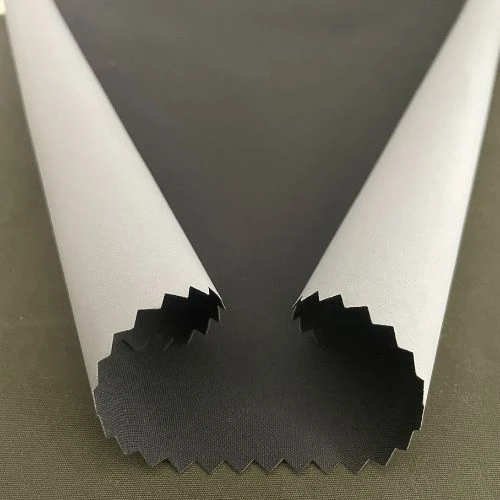

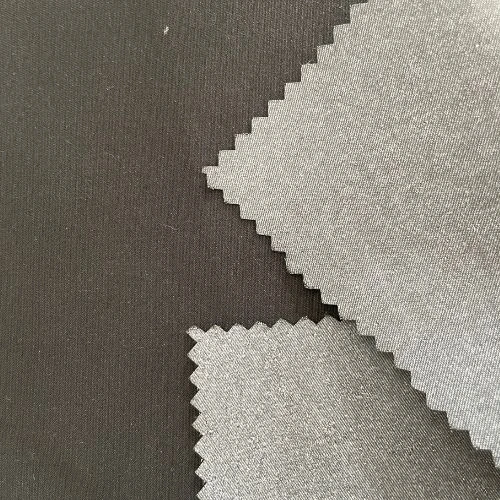

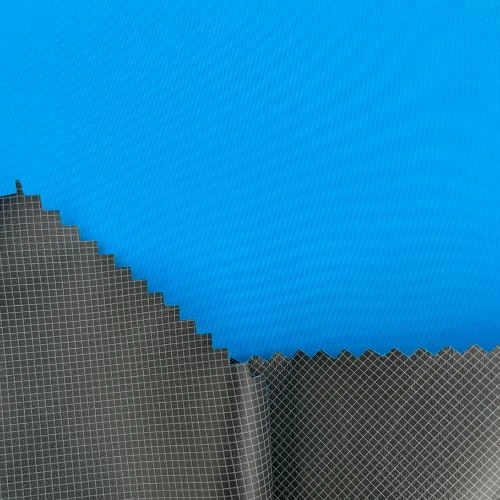

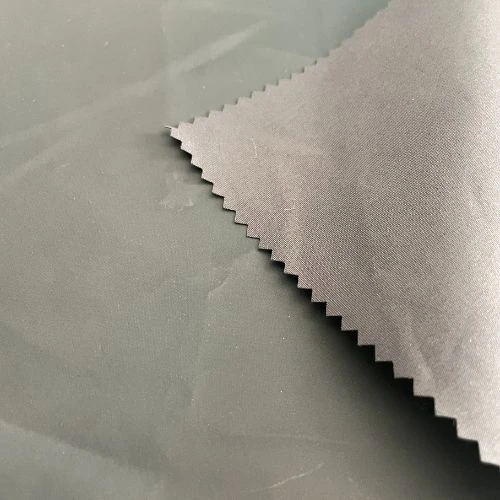

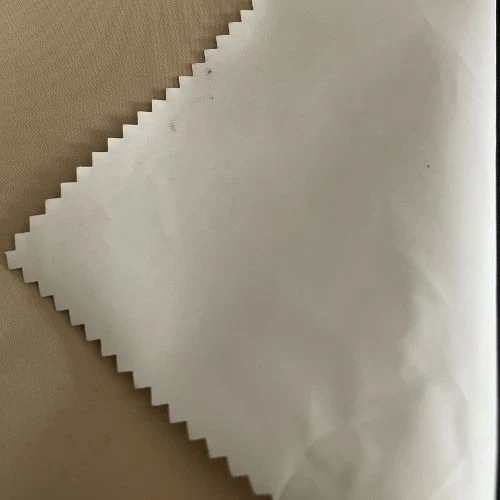

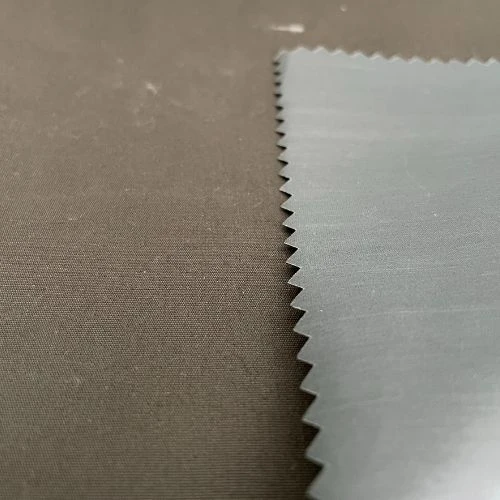

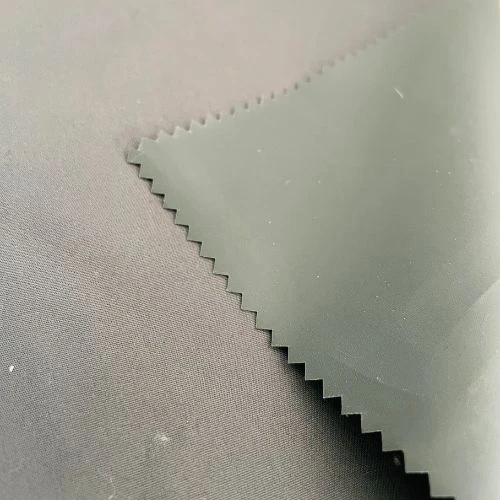

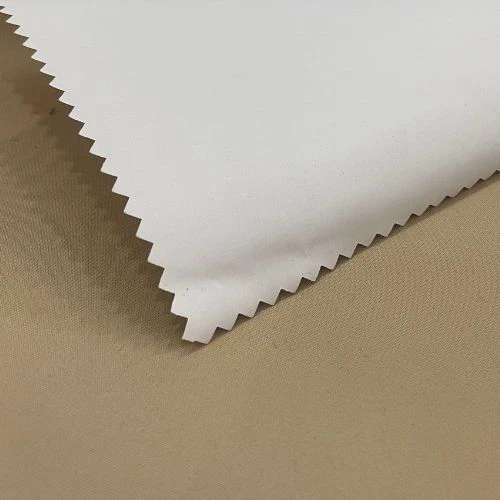

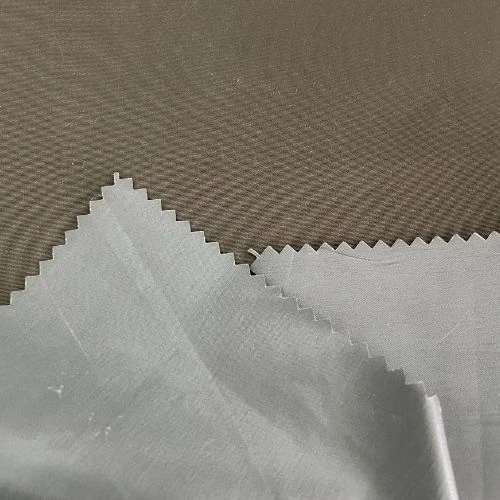

Plain and Twill Woven Microfiber:

The most common woven polyester microfiber fabrics are made using plain, twill, and satin weaves. The weight varies from 95 to 145 GSM. But the most common weight is 100 to 120 GSM, used to make swimshorts. Lightweight, woven polyester twill microfiber is an excellent choice for swimwear thanks to its added advantage of wicking moisture from the skin. This excellent characteristic makes it most suitable to use in the summer season.

Microsuede Fabric:

Microsuede fabric is a kind of plain polyester microfiber fabric, but it has a soft and smooth surface like suede and velvet. This kind of fabric has a noticeably low pile with almost the same feel as real suede in a cheaper option. It's more resistant to wear and stain than genuine suede. Microfiber suede can be woven, non-woven, and knitted. It's ideal for clothing, upholstery furniture, curtains, and footwear.

Microfleece Fabric:

Microfleece fabric is a type of knitted fleece fabric made of polyester microfiber. The main difference between fleece and microfleece lies in weight. Usually, fleece with less than 200 GSM is considered to be microfleece. It's super soft and highly absorbent, which makes it ideal for baby clothing, especially in diaper lining. This trendy soft fleece is widely used in making blankets, diapers, sanitary products, sweaters, and cleaning clothes.

Microterry Clothing:

One of the most popular microfiber fabrics is terry microfiber, which features the terry towel weave and knitted structure. Unlike regular terry towels made of other materials, micro terry is made of 100% polyester microfiber. The weight and pile height may vary depending upon the end use. It has high absorbency, making it suitable for making cleaning products like wipers and robes.

Characteristics of microfiber fabric

Microfiber is 30x finer than cotton, 10x finer than silk, 1/5th of human hair and invisible to the human naked eye. Consequently, microfiber fabric has versatile characteristics. Some of them are as follows:

- Exceptional strength, though the filaments are extremely fine.

- Improved breathability.

- Very soft and Luxurious.

- Excellent drape.

- Produce comfort with the blend of natural fibers.

- Non-abrasive, Hygienic, Durable.

- Absolutely appearance retention.

- Super absorbability, up to 25 times its weight.

- Could be made fabric windproof and water resistant.

- Super lightweight and so on.

What is microfiber fabric used for?

Microfiber fabric is used for its desirable properties, such as softness, absorbent, as well as diverse applications. Microfiber-made fabric is excellent for clothing cleaning fabric, furniture and sports gear. Microfiber can hold up to 7 times its weight in wet. The wet-absorbing quality makes microfibre a popular choice in the athletic wear manufacturing industry. Most of the common applications of microfibre fabric are producing cleaning products, especially cleaning fabric and mops.

The most powerful application of microfibre is that it can pick up bacteria from dirty surfaces. Consequently, microfibre fabric is often used for medical textile purposes. It can attract and rub bacteria & viruses from polluted surfaces. In this way, microfibre fabric can effectively catch and destroy bacteria. The use of microfiber fabric in the kitchen and hospital reduces the risk of germs and illnesses being spread. The tiny microfibers are non-abrasive, it can be used without damaging any surfaces, even when used with hard cleaning solutions.

When microfiber is used to manufacture regular apparel and furniture, the fibers don't split because it doesn’t need to be absorbent. It is simply soft, and comfortable. It could be used to create tough, but soft materials for clothing such as suits, jackets, skirts, and so on. Moreover, the ability to forge leather makes it a popular choice for the fashion industry.

Microfibre fabric Advantages

Some of the outstanding advantages of microfibers the following:

- Ultra-finer fabric like the most delicate silks or suede.

- Strong, Durable, as Cost Efficient

- Soft to the touch

- Having lightweight and High Wet Absorption properties

- Resists Shrinking and Stretching

- Easily could be treated with anti-bacterial chemicals

- Wrinkle and Lint Free

- Leaves no dust particles when rubbed with any surface

- Super-washed fabric, almost up to 500 times.

- Highly comfortable with insulation and breathability.

- No Fading in Color

- Long-lasting fabric

- Ease to care, etc.

Most artificial fabrics may not seem as eco-friendly as natural fabrics. But it could be called very sustainable. Case it doesn’t need so much water and chemicals during its production. No pesticides are used, and the dyeing methods never require huge water. But comparatively, cotton, the most popular fiber on the earth, requires a huge amount of water and is needed in the growing as well as the dyeing process and the other fiber also. In conclusion, it is super clear that microfiber will win in the following decades.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.