You’ve probably seen twill tape without realizing it. It hides inside your jacket seams, holds your apron strings, and keeps your workwear looking sharp. But what exactly is twill tape? Let’s break it down in simple terms.

Table Of Contents

Basics of Twill Tape

Definition and Structure

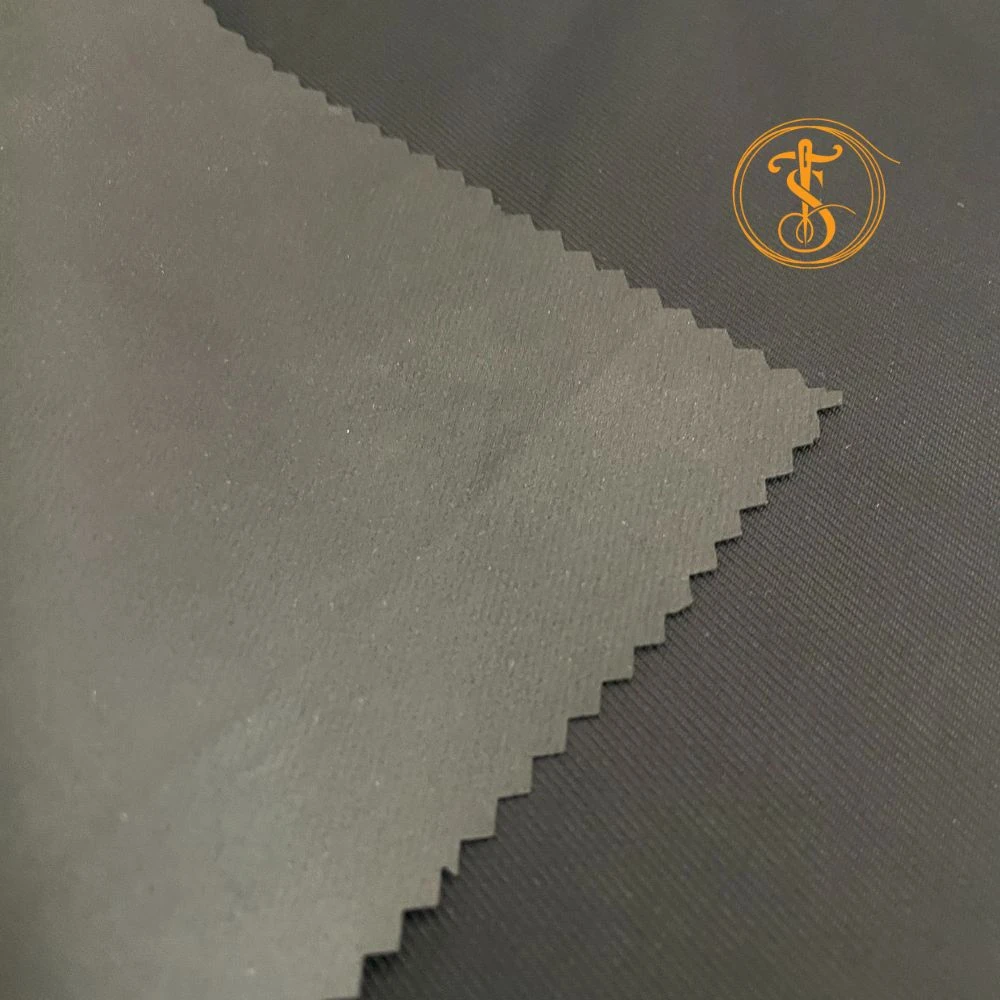

Twill tape is a flat woven fabric ribbon made using a twill weave pattern—those signature diagonal ribs you see on jeans or chinos. It’s not elastic like bias tape but is much stronger and more stable. The weave structure, usually 2/2 or 3/1 twill. It gives it both durability and a soft, flexible hand feel.

How Twill Tape Differs from Other Tapes

Unlike grosgrain (which has a ribbed surface) or bias tape (which is cut diagonally), twill tape is woven straight on the grain. This makes it less stretchy and perfect for reinforcement.

For example, a 1-inch cotton twill tape can withstand around 70–90 pounds of tension before breaking—something ordinary tapes can’t handle.

Types of Twill Tape Based on Material

Cotton Twill Tape

Cotton twill tape is the classic choice. Soft, breathable, and easy to dye—it’s the go-to for garments, aprons, and craft projects. Cotton versions often have widths ranging from 0.25 to 2 inches, depending on the use.

Polyester Twill Tape

Polyester twill tape is more resistant to moisture and abrasion. It’s common in sportswear and utility uniforms where strength matters more than comfort.

Nylon Twill Tape

When extreme toughness is needed—like in outdoor gear or military clothing—nylon twill tape steps in. It resists UV light, heat, and tearing better than cotton.

Key Features and Characteristics

Durability and Strength

The diagonal weave increases tensile strength by roughly 25–30% compared to plain-weave tapes. This makes it ideal for high-stress areas in clothing.

Flexibility and Soft Texture

Despite being strong, twill tape bends smoothly. It’s flexible enough for curves and edges—like necklines or hems—without puckering the fabric.

Availability in Various Widths and Colors

Manufacturers produce twill tape in more than 50 color shades and multiple widths (from 6 mm to 50 mm). That flexibility allows designers to match both function and style.

Common Applications

Seam Reinforcement and Binding Edges

Twill tape acts like a secret bodyguard for your garment’s seams. It reinforces the shoulders, necklines, or waist areas—preventing stretching and distortion after multiple washes.

Waistbands, Straps, and Drawstrings

Ever pulled the drawstring on your hoodie? That’s often twill tape in action. It’s strong, doesn’t twist easily, and maintains its shape even after hundreds of tugs.

Decorative Trims and Finishing Touches

Designers also use colored twill tapes as minimalist trims. Whether outlining denim pockets or adding a pop of contrast on a tote bag, it’s a stylish and functional element.

Twill Tape in Utility Wear and Industrial Applications

Protective and Functional Use

In heavy-duty garments like coveralls and lab coats, twill tape binds edges and reinforces closures. It prevents tearing under stress, increasing garment lifespan by an estimated 20–25%.

Military, Workwear, and Outdoor Gear

Twill tape is also used in tactical belts, military patches, and backpack handles. Nylon and polyester versions are especially popular in military-grade gear for their heat resistance and non-fraying edges.

How to Sew and Handle Twill Tape Properly

Cutting, Stitching, and Maintenance Tips

Cut twill tape with sharp scissors or a hot knife (for synthetics) to prevent fraying. Use a straight stitch with medium tension.

If you’re sewing cotton twill tape, prewash it—it can shrink up to 5–8%. Polyester and nylon variants don’t need prewashing.

For washing, keep temperatures below 40°C to maintain texture and prevent color fade.

Why Twill Tape Remains a Fashion Essential

Twill tape may seem humble, but it’s one of fashion’s unsung heroes. It strengthens, decorates, and simplifies. In an age of fast fashion, its durability supports sustainability—fewer replacements, less waste. A small strip of twill tape can literally extend a garment’s life.

Conclusion

Twill tape isn’t just a piece of fabric—it’s the backbone of quality construction. Whether reinforcing a shoulder seam, finishing a waistband, or adding charm to a dress, it blends function with finesse. It’s proof that even the simplest details can make a garment stand strong and last longer.

FAQs

1. Is twill tape the same as bias tape?

No. Bias tape is cut diagonally and stretches, while twill tape is woven straight with a diagonal pattern for strength.

2. Can I dye cotton twill tape?

Yes, cotton twill tape absorbs dye easily. Just prewash it first to remove any starch or finishing chemicals.

3. Where is twill tape used in uniforms?

It’s commonly used for reinforcing seams, waistbands, and attaching name labels in military and industrial uniforms.

4. How do I stop twill tape from fraying?

Use a lighter (for synthetics), fabric glue, or fold and stitch the ends to seal them neatly.

5. Is twill tape eco-friendly?

Cotton twill tape is biodegradable and recyclable, making it more sustainable than synthetic options.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.