Table Of Contents

Why Zipper Tests Matter

A zipper sits between a product’s promise and the customer’s frustration. One failed zipper can ruin a jacket, backpack, or pair of boots. Brands face returns, warranty claims, and a dent in reputation. Labs and factories run tests to prevent that outcome.

Industry wants two things from zippers: reliable strength and long life. Strength means the zipper resists sudden force. Durability means the zipper still works after repeated use and rough conditions.

Quick numbers to hold in mind: many product teams aim for 10,000 cycles for high-end luggage and 1,000–5,000 cycles for garments. Those numbers guide test plans.

Real-world failure modes

- Teeth break or deform.

- The slider detaches or strips the teeth.

- Tape tears away from fabric.

- Corrosion causes a seizure.

- Dirt or sand causes jamming.

Who cares: brands, labs, end users

- Outdoor and luggage brands care most.

- Apparel teams care about comfort and function.

- Testing labs provide objective pass/fail data.

- Consumers demand value and reliability.

Core tests for zipper strength

Pull (tensile) test

%20test_1762770419.webp)

Purpose: measure the maximum force that zipper components withstand before failure.

Procedure overview:

- Clamp zipper tape ends in a tensile tester.

- Pull at constant speed (e.g., 50 mm/min) until failure.

- Record peak load in Newtons or kilograms-force.

What to watch:

- Mode of failure: tape tear, teeth break, or slider slip.

- Peak load value. That number guides design margins.

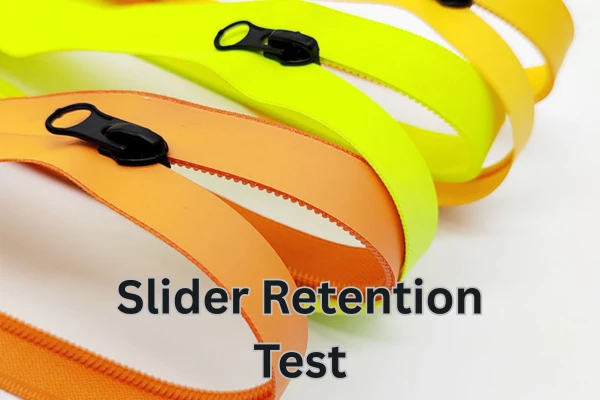

Slider retention test

Purpose: check the slider keeps teeth engaged under load.

Procedure overview:

- Engage the zipper in the closed position.

- Apply a transverse force on the slider or on the tape while pulling.

- Observe the slider pop-off or track misalignment.

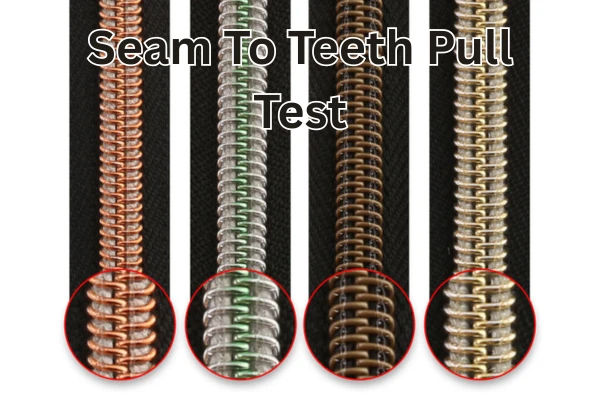

Seam-to-teeth pull test

Purpose: measure the attachment strength of zipper tape to garment fabric or seam.

Procedure overview:

- Mount the sewn sample in the clamp.

- Pull perpendicular to the seam.

- Note the force where the tape separates from the fabric or the seam opens.

This test prevents failures where the garment fails before the zipper.

Core tests for zipper durability

Cycle (fatigue) test

Purpose: simulate repeated open/close cycles.

Procedure overview:

- Use a motorized cycle tester.

- Run a set number of cycles (e.g., 1,000; 5,000; 10,000).

- Inspect at intervals for wear, jamming, and slider loosening.

Results:

- Count cycles until failure.

- Record change in pull force and operational smoothness.

Corrosion and environment test

Purpose: evaluate performance after exposure to moisture, salt, or chemicals.

Procedure overview:

- Expose the sample to salt spray, humidity, or UV.

- Perform function and visual checks.

- Rate appearance and function loss.

Abrasion and snag test

Purpose: measure resistance to grit and friction.

Procedure overview:

- Rub tape or teeth under controlled load using an abrasion tester.

- Inspect for tooth wear, tape fuzz, or jamming.

How to set pass/fail criteria

Risk-based thresholds

Set thresholds based on product type:

- Luggage: high threshold (10k cycles, high pull strength).

- Lightweight apparel: moderate threshold (1–3k cycles).

- Kidswear: lower threshold but must resist tape pull-out.

Sample size and statistics

Use simple stats to reduce risk:

- Test at least 5–10 samples per batch for small runs.

- For large runs, use AQL sampling or statistical plans.

- Report mean, median, and standard deviation. One failure in 10 may not doom a batch, but it signals a root cause.

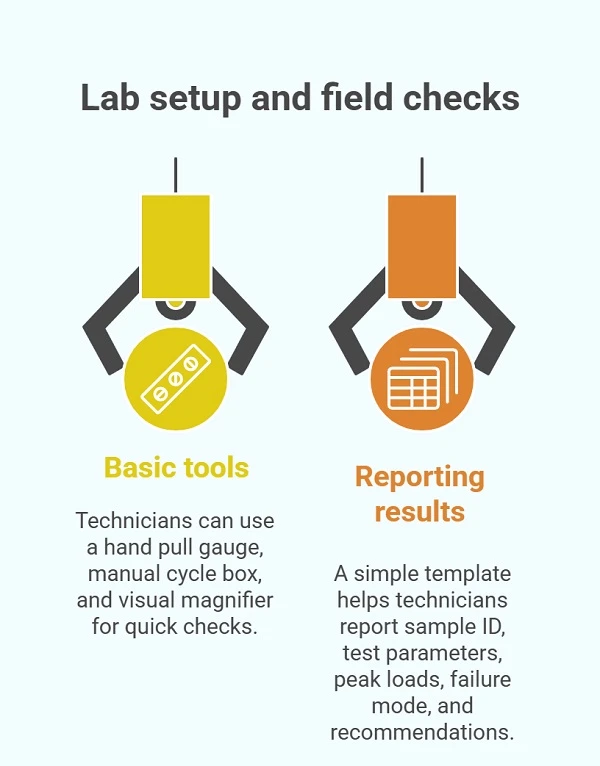

Practical lab setup and inexpensive field checks

Basic tools for quick checks

If lab gear is not available, technicians can use:

- Hand pull gauge (measure force manually).

- Manual cycle box (count cycles with motor or hand crank).

- Visual magnifier and marker for pre/post-inspection.

How technicians report results

A simple template helps:

- Sample ID.

- Test type and parameters.

- Peak loads or cycle counts.

- Failure mode and photos.

- Recommendation (accept, rework, reject).

Good reports speed decisions and fix problems fast.

Conclusion

Zipper performance depends on both strength and durability. Run a mix of tensile, cycle, corrosion, and abrasion tests. Use risk-based thresholds. Apply basic statistics to avoid bad batches. Keep records and adjust specs when field returns rise. A small test now saves a big recall later.

FAQs

1. How often should a zipper undergo cycle tests?

For new designs, run full cycle tests during validation: 1 sample at 1,000 cycles, another at 5,000, and one at 10,000 if the product targets heavy use.

2. Does a metal or plastic zipper last longer?

No single answer. Metal teeth offer higher raw strength. Plastic teeth resist corrosion and tolerate grit better. Choose by product use.

3. Can a field technician perform a reliable pull test?

Yes. A simple handheld pull gauge provides useful relative data. For certification, use a calibrated tensile tester.

4. What number signals immediate failure in cycle tests?

If a zipper fails within 10% of target cycles, treat that as serious. For example, a 10k-target zipper failing at 9k needs root cause work.

5. How to prevent corrosion in coastal conditions?

Use plastic teeth or stainless-coated metal, apply protective coatings, and design drainage in product construction.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.