Every garment tells a story. Some stories look sharp. Some feel soft. A lot of this magic starts with small details. Piping and binding trim create most of that difference. You see both in shirts, jackets, dresses, lingerie, sportswear, and bags. They look similar, but the purpose is not the same. A buyer often asks this question. A junior merchandiser often hesitates. A sewing operator even mixes them up on a busy day. Let’s clear the air.

Table Of Contents

What Is Piping Trim?

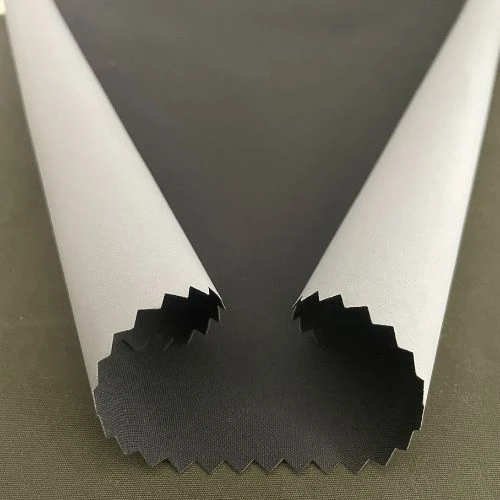

Piping trim is a narrow fabric strip with a cord inside. The cord gives it shape. It forms a raised edge. Most piping widths fall between 3 mm to 8 mm. Around 70% of piping uses cotton or polyester cores. Many brands use piping to create sharp outlines that stand out on a garment.

Key Features of Piping

- A cord stays inside the strip.

- It forms a round edge.

- It sits between two fabric panels.

- It adds structure and definition.

- It shows a strong contrast effect.

Uses of Piping in Garments

Piping appears in many categories.

- Home textiles: Cushions, pillow covers, quilts.

- Formal wear: Suits, blazers, collars, and lapels.

- Ethnic wear: Kurta necklines, sleeves.

- Bags: Wallet edges, travel bags, backpacks.

A 2023 apparel survey shows that over 40% of decorative trims in home textiles use piping because of its durability.

Advantages of Piping

- Adds a premium look.

- Increases edge strength.

- Creates bold contrast.

- Enhances shape retention.

What Is Binding Trim?

Binding trim is a flat strip used to finish raw edges. No cord. No raised shape. Just a clean, neat edge. The binding width ranges from 12 mm to 30 mm. Many factories use knit binding for stretch garments and woven binding for structured products.

Key Features of Binding

- No internal filler.

- Fully covers raw fabric edges.

- Offers a smooth, flat finish.

- Can match or contrast the garment surface.

Uses of Binding in Garments

Binding works everywhere.

- Necklines and armholes

- Hems

- Waistbands

- Seam finishing

- Activewear edge control

More than 55% of knit sportswear necklines use binding because it holds shape under stress.

Advantages of Binding

- Prevents fraying.

- Improves fabric durability.

- Produces a clean and professional edge.

- Flexible across woven and knit garments.

Main Difference Between Piping and Binding Trim

This is the part most people look for. Piping and binding play two different roles. One decorates. One protects. One stands out. One blends in. Both matter.

Structural Differences

|

Feature |

Piping |

Binding |

|

Shape |

Raised, rounded |

Flat |

|

Internal Cord |

Yes |

No |

|

Width |

3–8 mm (approx.) |

12–30 mm (approx.) |

The cord alone changes the whole identity. That small filler creates a dimension that binding never gives.

Functional Differences

- Piping adds decoration.

- Binding finishes edges.

If you want a clean finish, go for binding. If you want a bold highlight line, piping wins.

Visual and Aesthetic Differences

- A garment with piping looks sharper. A garment with a binding looks neater.

- Piping creates a 3D accent.

- The binding stays subtle and smooth.

- Both elevate the garment, but in different ways.

How to Choose Between Piping and Binding

A designer chooses based on function, fabric, and price. A production team checks ease of sewing and strength. A buyer checks the final aesthetics.

Points to Consider

Fabric Type

- Light fabrics suit binding.

- Medium and heavy fabrics suit piping.

Garment Category

- Sportswear prefers binding.

- Blazers and bags prefer piping.

Strength Requirement

If you need stronger edges, piping works well because of the cord core. If you only need clean edges, binding is enough.

Conclusion

Piping and binding trims look simple, but they make a huge difference. Piping adds drama. Binding adds order. Piping stands out. Binding blends in. One decorates. One protects the edges. Once you know the difference, trim selection becomes easier. Your garment quality improves. Your design confidence grows. Even your QC team breathes easier. Small parts, big impact.

FAQs

1. Why do designers use piping instead of binding?

Designers use piping when they want a raised accent line that stands out.

2. Which trim is stronger: piping or binding?

Piping offers better strength due to the cord inside. Binding protects edges but stays flat.

3. Can binding replace piping?

No. Binding covers edges, while piping decorates seams. They serve different functions.

4. What fabric works best for piping?

Cotton and polyester blends work well. They hold shape better around the cord.

5. Does binding work for both woven and knit garments?

Yes. Knit binding suits stretch garments. Woven binding suits structured garments

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.