Table Of Contents

What is Mesh Fabric?

Mesh fabric is a loose-knit fabric available in a range of weights and thicknesses. It is a broad term for fabric characterized by open spaces between the yarns. In mesh fabric, yarns are knit together in a grid pattern to form lots of tiny holes. Its lightweight heft and permeable texture typifies it. A variety of different synthetic fiber types are used in mesh fiber compositions.

Mesh fabric is also known as Power mesh, tulle, or Powernet. It may be woven, knit, net, lace, crocheted, etc. It is known for its characteristic screen-like weave. Mesh fabric is a go-to for shirts, leggings, athletic jerseys, athletic shorts, lingerie, shapewear, workout apparel, screens for screen printing, net, and so on.

|

Fabric Name |

Mesh Fabric |

|

Reason for the Name |

Derived from its grid-like, perforated structure that resembles a mesh. |

|

Also Known As |

Netting Fabric, Spacer Mesh |

|

Manufacturing Process |

Warp knitting, Raschel knitting, or circular knitting; also includes weaving with perforations. |

|

Appearance |

Lightweight, grid-like holes, semi-transparent or opaque depending on construction. |

|

HPI (Hole Per Inch) |

20–60 HPI |

|

GSM Range |

50–350 GSM |

|

Composition Range |

100% Polyester, 100% Nylon, Polyester/Nylon blends, or Spandex blends. |

|

Construction Range |

Single-layer, double-layer, or sandwich construction for added thickness and durability. |

|

Functionality |

TPU (Thermoplastic Polyurethane), PU (Polyurethane), AC (Acrylic), W/R (Water-Resistant), PV (Polyvinyl), Flame Retardant. |

|

Count Variations |

75D–300D (Denier). |

|

Full Width |

57/58", 59/60", 71/73" |

|

Fabric Breathability |

Highly breathable due to perforations; air circulation optimized in open constructions. |

|

Moisture-Wicking Abilities |

High (especially with polyester and treated fabrics). |

|

Heat Retention Abilities |

Low (designed for ventilation rather than insulation). |

|

Stretchability |

Moderate to high when blended with Spandex or elastane. |

|

Prone to Pilling/Bubbling |

Low, especially in nylon and treated polyester variants. |

|

Country First Produced |

France (1830s), originally for tulle and netting. |

|

Biggest Exporter Country |

China (~65% of global exports). |

|

Recommended Washing Temps |

Cold to warm water (30–40°C) for standard polyester/nylon mesh. |

|

Applications |

Sportswear, athleisure, backpacks, automotive seat covers, medical fabrics, footwear linings, mosquito nets, industrial filtration, upholstery. |

Types of Mesh Fabric

Based on structure, there are a few https://texsuppliers.com/different-types-of-mesh-applicationhttps://texsuppliers.com/different-types-of-mesh-application, including weaving and knitting. Multiple terms are used to refer to the same mesh fabric variant. Based on design and structure, mesh fabric is classified into 4 categories.

- 2x2 Mesh

- 4x4 Mesh

- Tulle Mesh

- Power Mesh

- Versailles Mesh

- Hole Mesh

- Dobbie Mesh/ Dobby Mesh

- Pique Mesh

- Bird's Eye Mesh

2x2 Mesh

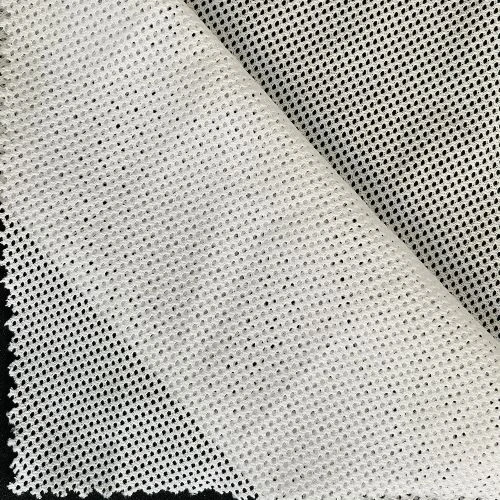

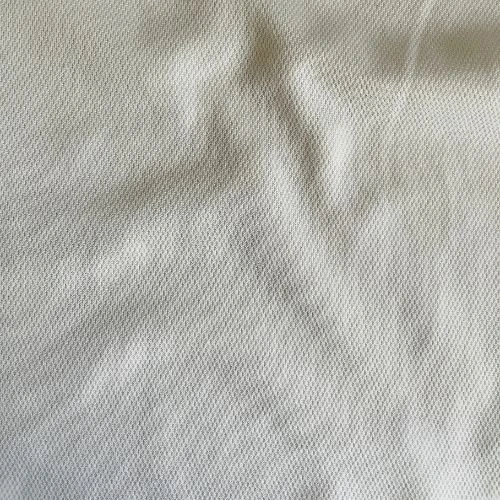

Figure: 2x2 Mesh Fabric

2X2 mesh indicates that there are two openings in one linear inch. It could be 100% polyester, which is cheaper and more affordable. It has good air permeability and is suitable for making summer clothes. This fabric is usually used for the lining of shorts, and sportswear.

4x4 Mesh Fabric

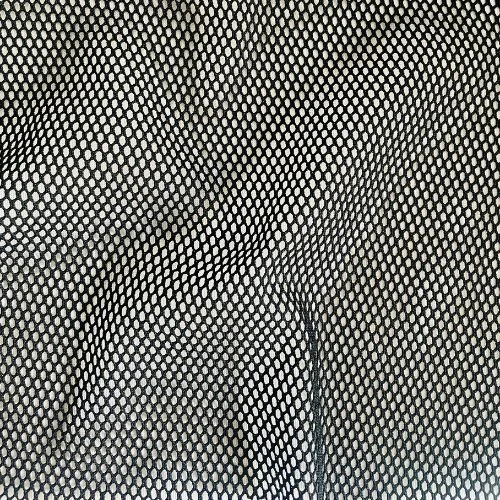

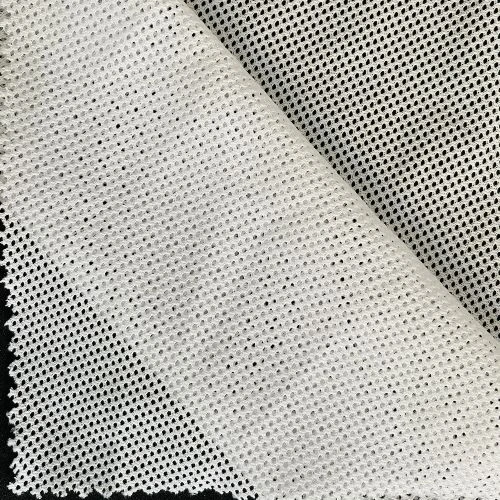

Figure: 4x4 Mesh Fabric

4x4 Mesh Fabric is a type of wire mesh where there are four openings per linear inch. It is very breathable and elastic, making it a popular choice for athletic wear and shapewear.

Tulle Fabric:

Tulle mesh fabric is most frequently used in brightly-colored dancewear clothing. In some special cases, tulle mesh fabric could be made from silk to mitigate the environmental impact of this type of mesh fabric.

Power Mesh Fabric:

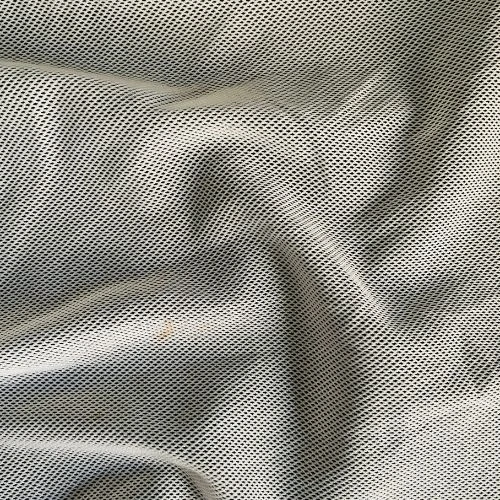

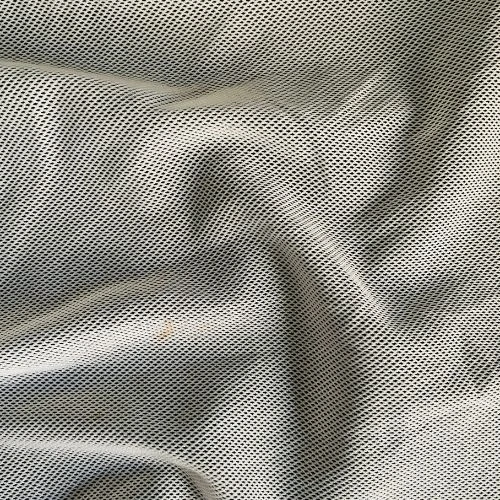

Figure: 100% Polyester Power Mesh Fabric

Power mesh has excellent compression abilities. It's composited of nylon-spandex material where that spandex percentage is high. That's why it's commonly used in a variety of sportswear and shapewear garments, where the wearer needs more movement. Sometimes power mesh fabric is also used in home decor.

Powernet mesh fabric has features of a relatively dense weave. It is commonly used in shaping apparel such as top tights, bras, lingerie, and control slips. In some cases, the term "powernet" fabric is used interchangeably with "power mesh fabric."

Versailles Mesh

Versailles Mesh fabric imparts an intricate interplay of extreme variation. The silvering moves from light to dark. The surface is broken by random streaking and spots, like that of an aged mirror.

Hole Mesh

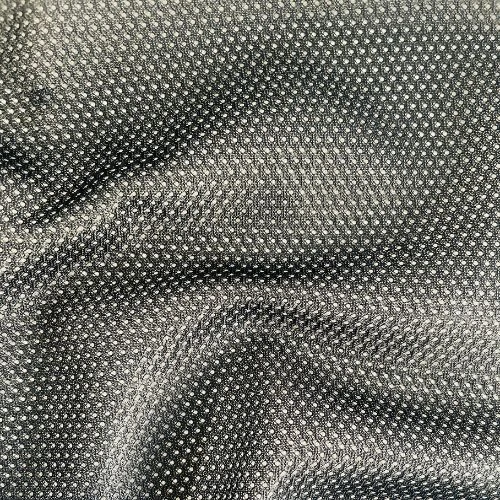

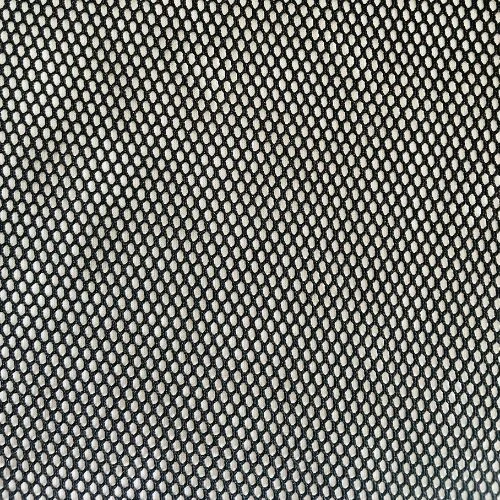

Figure: Polyester Hole Mesh Fabric

Roll mesh fabric is also known as wire mesh. It is produced on looms as mesh rolls. The meshes are stored on rolls. All further processing steps are then performed based on this roll material.

Dobby Mesh

Dobbie or Dobby mesh is produced on the dobby loom. Small geometric patterns and additional texture in the fabric characterize it. The warp and weft yarns could be the same color or different.

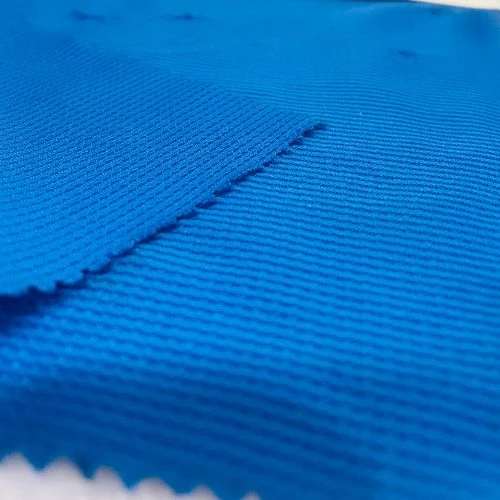

Pique Mesh

pk mesh is one of the most popular mesh fabrics. It is widely used in polo shirts and other sportswear. Pk mesh's ability to retain its colors and sustainable shape with time makes it great for athletic wear. Because of its water-resistant qualities, the pk mesh is also used in home textile products,

How is mesh fabric made?

- Extracting the polyamide monomer: Polyamide monomers are extracted from refined petroleum oil.

- Combining with other acids: These monomers are then reacted with various forms of acid to make polymers.

- Melting and Spinning: They are melted and forced through spinnerets to make polymer stands.

- Loading and shipping: Once these strands have cooled, they can be loaded onto spools and shipped to textile manufacturing facilities to be made into mesh fabric.

- Finishing: The manufacturing of mesh fabric will dye their polyester or nylon fibres before they wave them into the fabric.

- Weaving: Textile manufacturers can then weave these fibres in a number of different ways to create various forms of mesh.

What is mesh fabric made of?

Mesh fabric is typically made from polyester, polyamide, or nylon. The synthetic fibres are woven or knitted to create a flexible, net-like fabric that has a huge range of uses. Additionally, mesh structured materials can also be created from metals for a sturdy and more structured material, often for industrial purposes.

On the basis of components, mesh fabric could be classified into 3 types. These areas:

- Polyester Mesh

- Nylon Mesh

- Spandex ( Poly Spandex/ Nylon Spandex)

Polyester Mesh Fabric:

Polyester mesh fabrics are used to make most types of mesh-made sportswear and athletic clothing. Due to its incredibly lightweight, highly breathable, and noticeable ability to wick moisture, polyester mesh fabric mass-used in sportswear.

Nylon mesh Fabric:

Beekeeping veils are one of the most iconic applications of nylon mesh fabric. This particular type of mesh fabric is rarely used to make apparel. It is generally used to make items like beekeeping veils, tent screens, laundry bags, etc. Additionally, nylon mesh fabric is used to make lightweight garments like evening dresses and lingerie.

Splace Mesh fabric

Splace Mesh (Spacer mesh) fabric is known as 3D mesh and sandwich mesh is essentially 3 separate layers of fabric knit together. It could be Poly Spandex or Nylon Spandex. A face and a back are connected by a monofilament yarn to produce the “connecting cushion”. It is used for decorative purposes in interior design, and clothing design. It is usually used for visual merchandising, wall treatments in geotextiles, curtains, clothing or, shoe design, draping, etc.

Mesh Fabric Properties:

Nylon and polyester both could be used to mesh fabrics by knitting mesh fabric or weaving mesh fabric. Though each type is used to produce mesh solutions for many different purposes. As synthetic fibres are used in mesh fibre composites, it has several similar beneficial properties such as:

- Durability

- Very breathable

- Medium comfort moisture

- High Stretchability

- Low Heat retention abilities

- Lightweight

- Resistance to mildew

- Tear resistance

- Easy to clean, and so on.

Nylon Vs Polyester Mesh

Mesh fabric is typically made from polyester, polyamide, or nylon. But these two types of mesh don’t seem all that different. Both synthetics fibre-made fabric can be used for similar applications, though there are some differences between the two.

Nylon is a manmade fibre, made from polyamides. But polyester is composed of polyester materials and made using plant materials. Therefore, polyester is more fibrous to the touch and has the feel of nylon that resembles silk. Nylon has more stretch to it than polyester. Nylon is longer-lasting than polyester. Sustainable items may be the better option to go with nylon-made mesh fabric.

Application of Mesh Fabric

- Sportswear: Swiming wear

- Wedding Wear: Party/ Wedding Dress

- Tents and camping supplies: To manufacture products for activities like sports, camping, hunting and fishing, and more.

- Protective sports netting: Golf simulator, Volleyball impact screens and nets

- Occupational Safety equipment: Safety flags, High-visibility safety vests, Cut-resistant safety garments

- Geo Textile: Mops and squeegees, Tarps, Bags, Industrial filtration.

- Agriculture: Aquaculture, Horticulture,

- Aeronautics, Automotive Marine: Seat-mounted literature pockets, Safety harnesses, Cargo nets, Aviation curtains.

- Healthcare: Patient lift systems, Mesh curtains, IV bag support mesh, Orthopedic braces.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.